PVC pipeline cutting device

A technology for pipe cutting and cutting discs, which is applied in cleaning methods and utensils, cleaning hollow objects, chemical instruments and methods, etc., can solve the problems of PVC pipe cutting surface not smooth enough, butt joint PVC pipe leakage, etc., to achieve enhanced cutting effect and guarantee Cleanliness and the effect of increasing the fixing force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

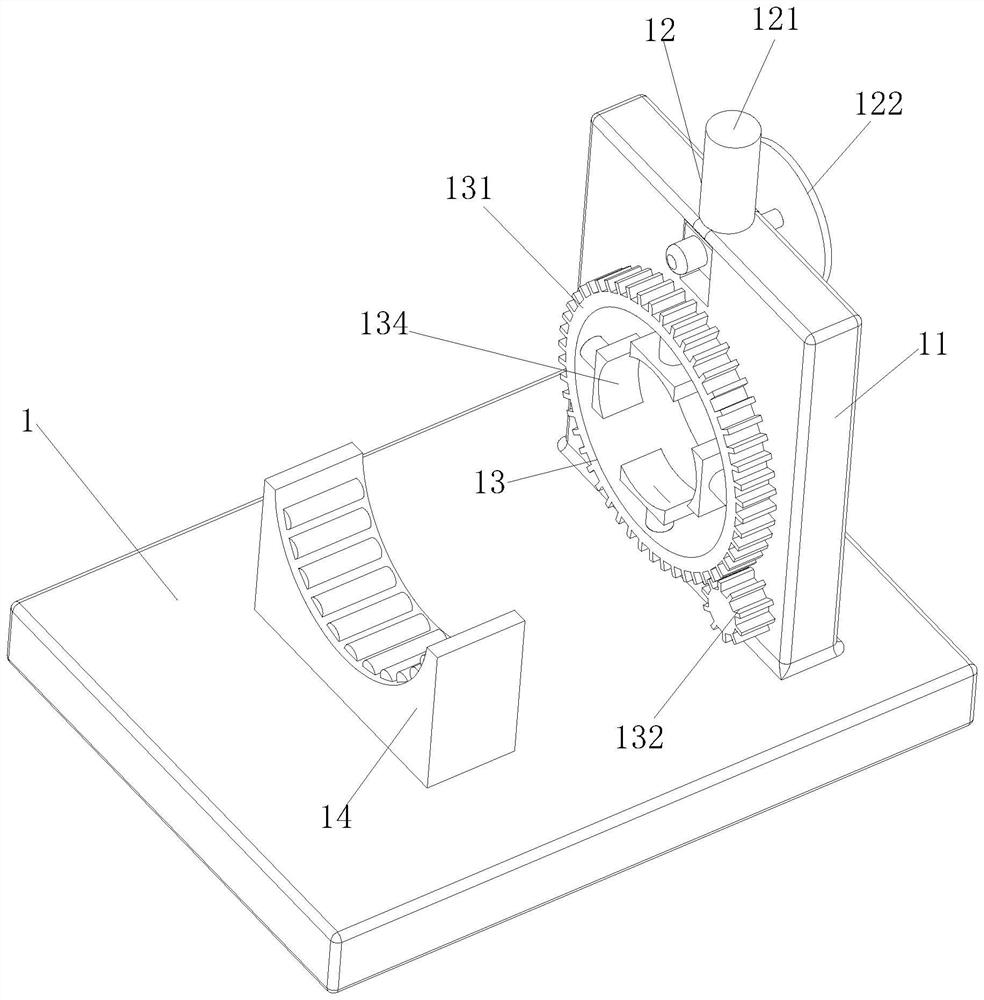

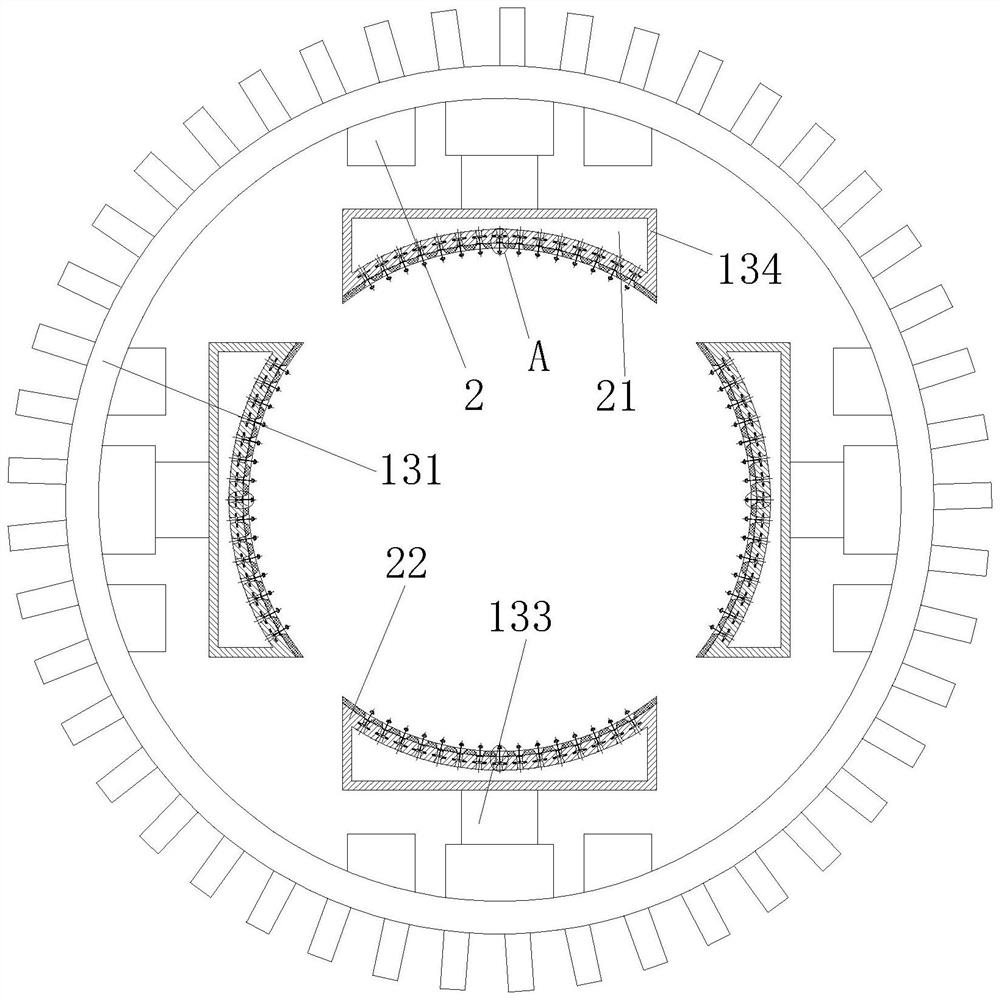

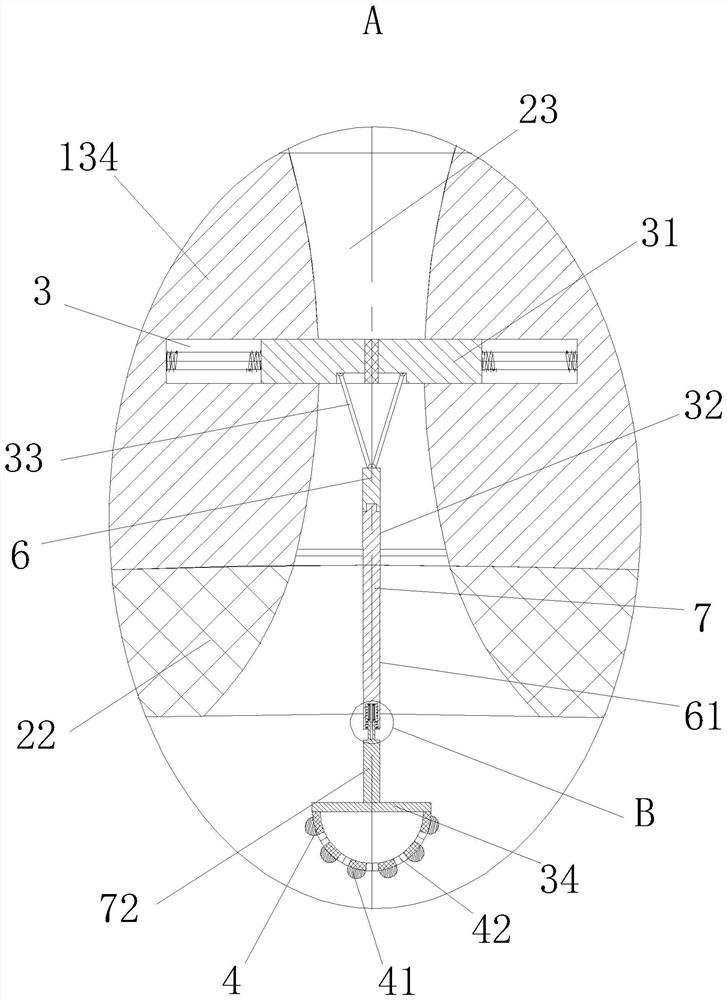

[0030] As an embodiment of the invention, the side wall of the clamping block 134 close to the center point of the gear disc 131 is an arc wall; A first cavity 21 is opened in the clamping block 134; The gear disc 131 is fixedly connected with a set of negative pressure machines 2; The arc wall of the clamping block 134 is fixedly connected with a first rubber layer 22; The side wall of the first cavity 21 close to the arc wall of the clamping block 134 is provided with a first through hole 23; The first through hole 23 penetrates the first rubber layer 22; The negative pressure machine 2 and the first cavity 21 are connected with each other; During operation, the outer surface of the PVC pipe itself is relatively smooth. When the clamping block 134 clamps and fixes the PVC pipe, it is necessary to apply a large extrusion force to ensure the fixing effect of the clamping block 134 on the PVC pipe and prevent the PVC pipe from slipping. However, the large extrusion force is easy to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com