Magneto-rheological shock absorber

A magneto-rheological shock absorber and magneto-rheological fluid technology, applied in shock absorbers, springs/shock absorbers, shock absorbers, etc., can solve problems such as inability to apply impact loads and inability to alleviate impact loads

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with accompanying drawing.

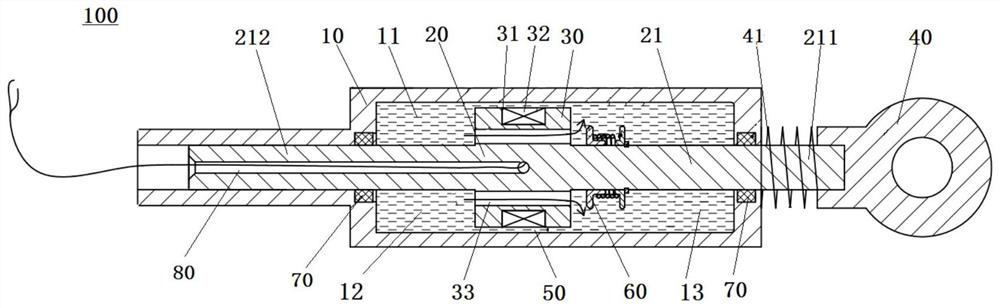

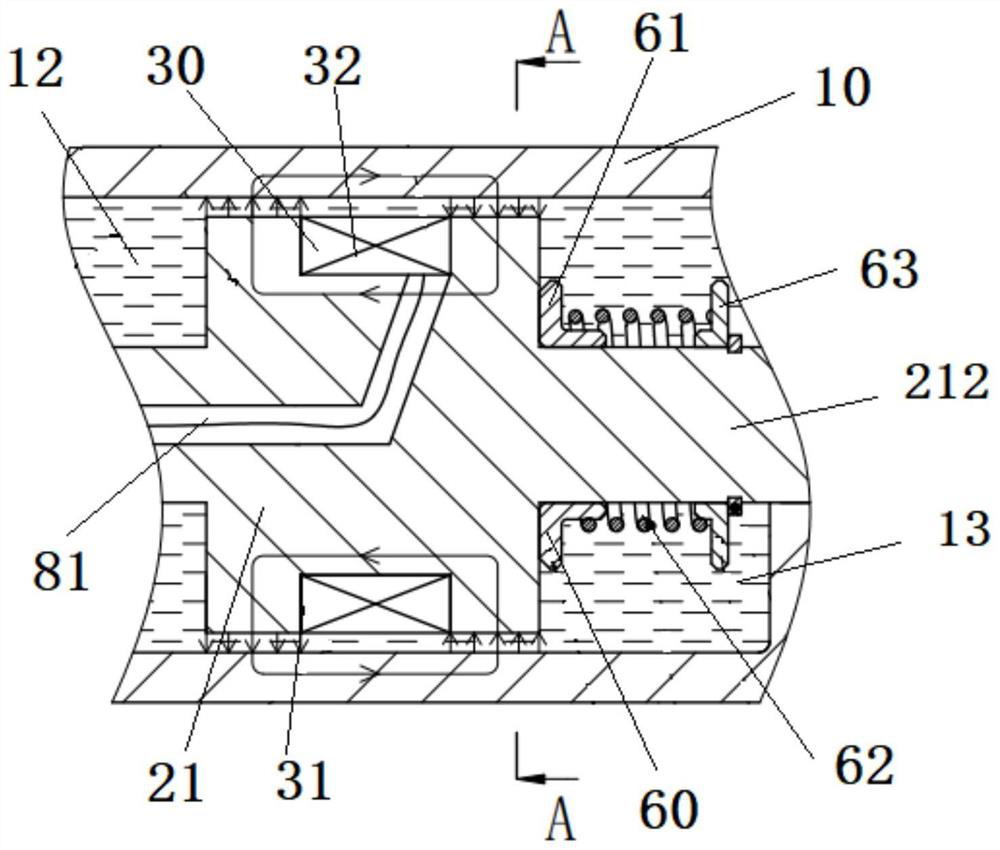

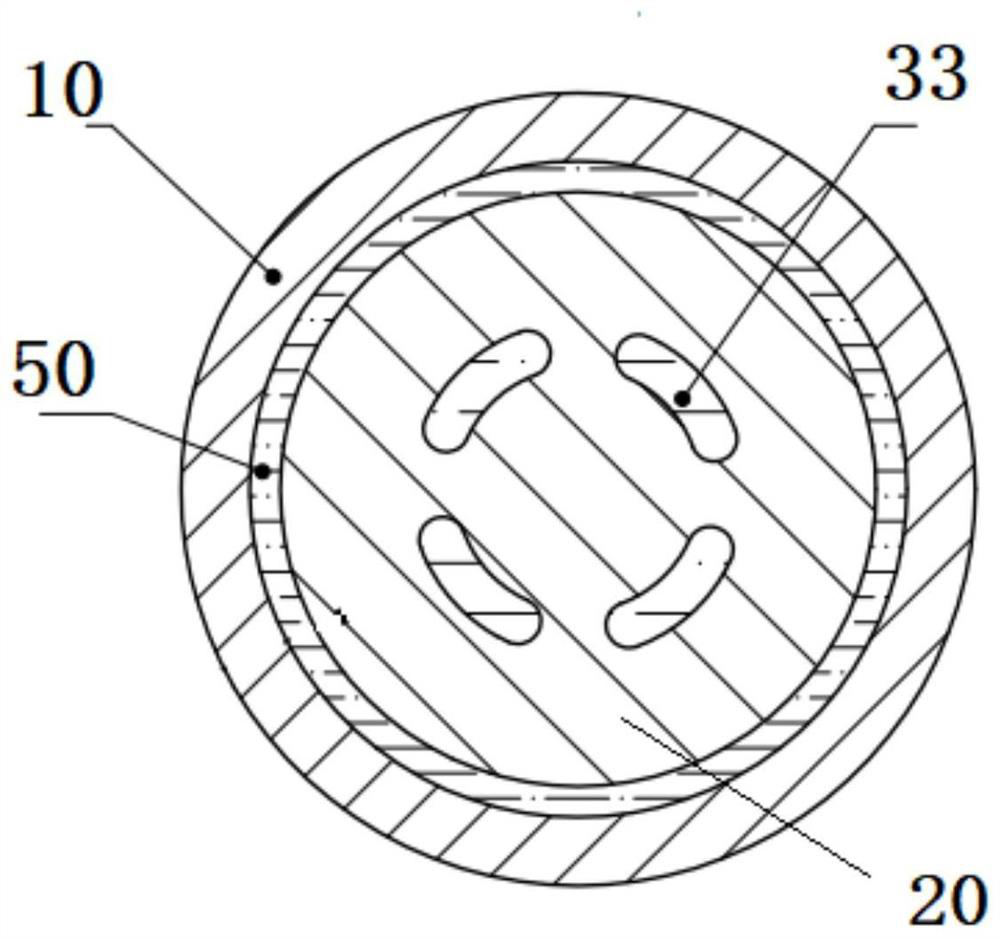

[0020] figure 1 The structure of the magneto-rheological shock absorber 100 according to the present invention is schematically shown. like figure 1 As shown, the magneto-rheological shock absorber 100 according to the present invention includes a cylinder 10 and a piston unit 20 . Therein, the cylinder body 10 is configured as a hollow sleeve, and a chamber 11 is formed in the cylinder body 10 . Chamber 11 is used to accommodate magnetorheological fluid (not shown). The piston unit 20 is disposed within the chamber 11 of the cylinder 10 and is capable of reciprocating movement within the chamber 11 of the cylinder 10 . Magneto-rheological fluid (MRF) is a new type of intelligent liquid material, which is mainly composed of non-magnetic liquid and high magnetic permeability and low hysteresis micro-magnetic particles uniformly dispersed in it. Under the action of a mag...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com