Performance detection equipment for heat dissipation material and detection method thereof

A heat-dissipating material and testing equipment technology, applied in the field of performance testing equipment for heat-dissipating materials, can solve problems such as inaccurate detection of heat-dissipating materials and detection errors, and achieve the effects of ensuring reputation, avoiding detection errors, and ensuring accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be described in detail below in conjunction with various embodiments shown in the drawings. However, these embodiments do not limit the present invention, and structural, method, or functional changes made by those skilled in the art according to these embodiments are included in the protection scope of the present invention.

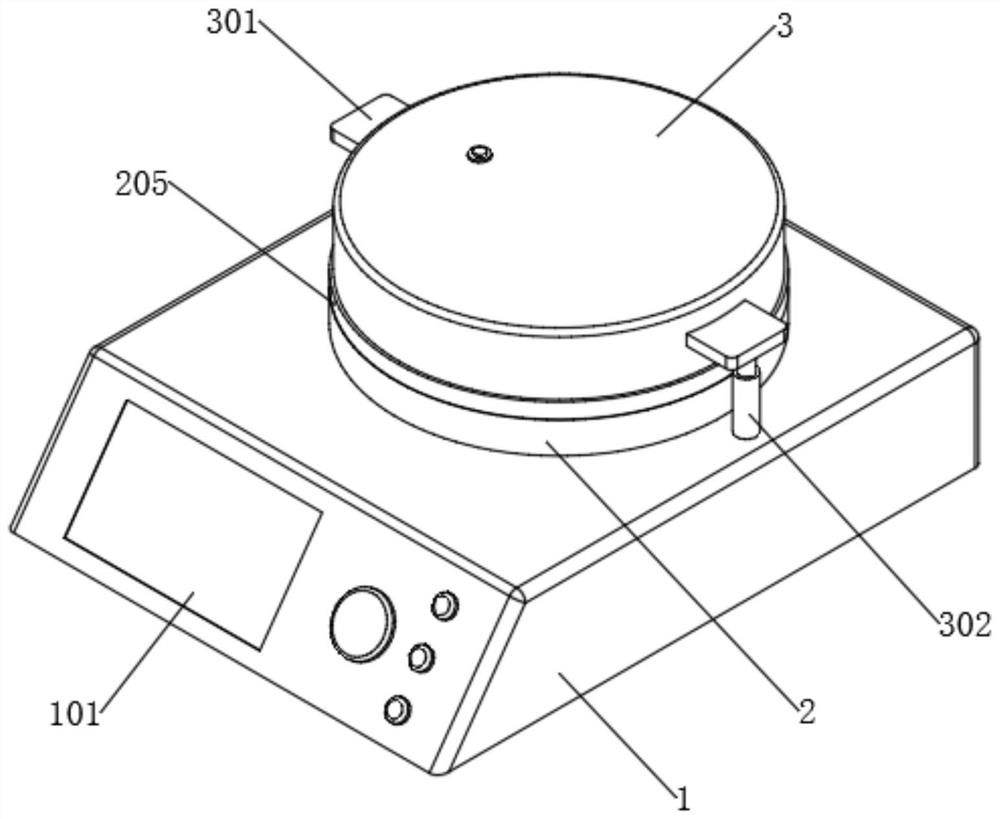

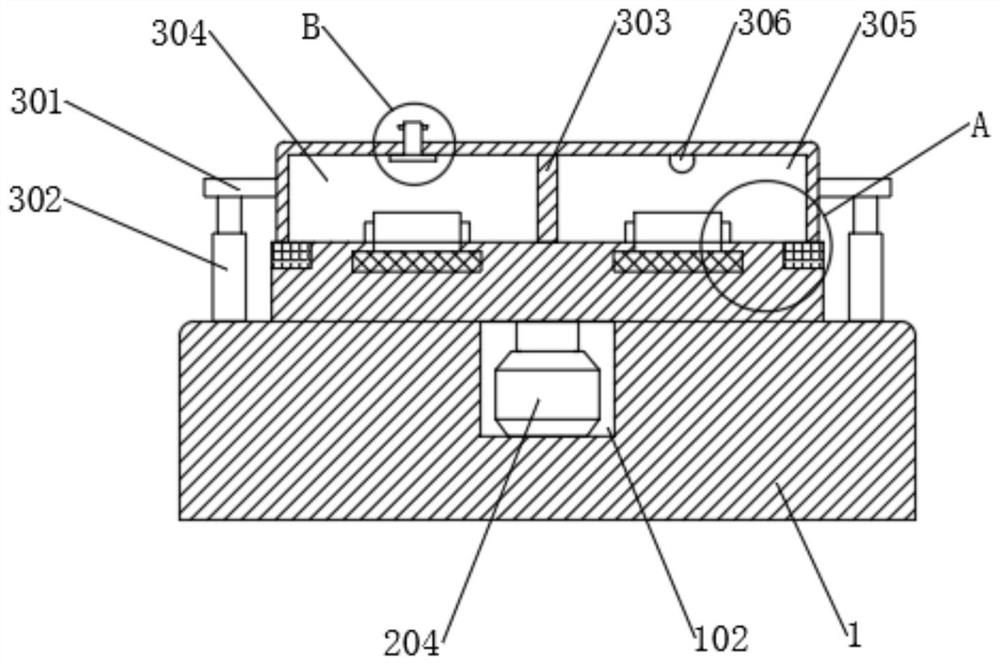

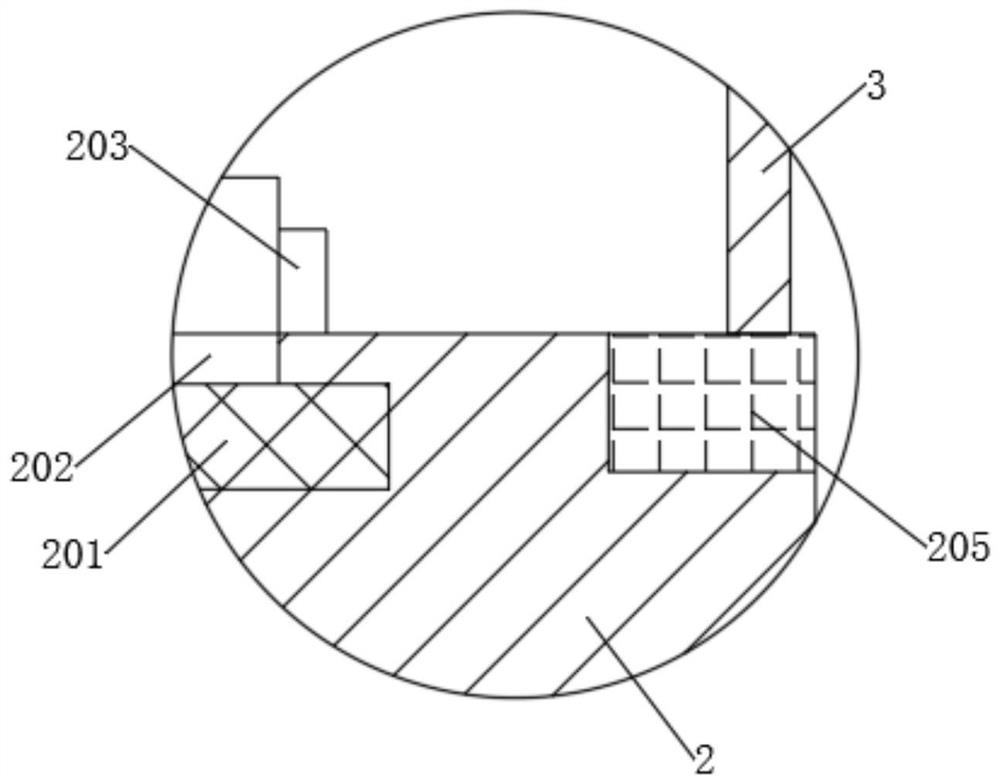

[0036] The invention discloses a performance testing device for heat dissipation materials and a testing method thereof, referring to Figure 1-Figure 7 As shown, it includes a base 1 , a testing platform 2 and a sealing cover 3 .

[0037] Wherein, a control panel 101 is installed on the base 1 , which is convenient for inspectors to control, including the running state of the heating plate 201 , the rotation direction of the motor 204 , the telescopic state of the telescopic member 302 and the operation of the sensor 306 .

[0038] In addition, an installation cavity 102 is provided at the center of the base 1 for ins...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com