Miniature LED chip, preparation method thereof and eutectic structure comprising miniature LED chip

A LED chip, miniature technology, applied in the direction of semiconductor devices, electrical components, circuits, etc., can solve the problems that the positive and negative electrodes are not on the same plane, the metal eutectic point of the negative electrode and the positive electrode are not on the same plane, and the eutectic effect cannot be achieved.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

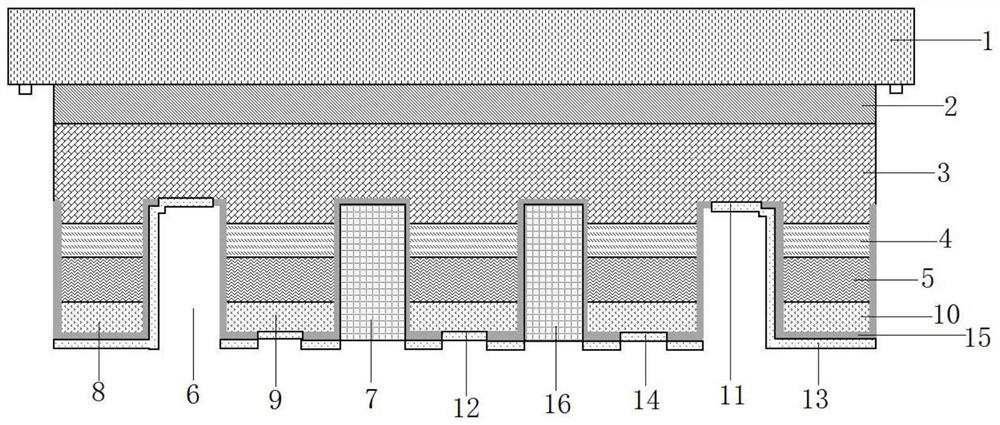

[0057] refer to figure 1 . The micro-LED chip of this embodiment includes a substrate 1, and a U-type gallium nitride layer 2, an N-type gallium nitride layer 3, a light-emitting layer 4, and a P-type gallium nitride layer extending outward from one side of the substrate 1 in sequence. Gallium nitride layer 5; the surface of the P-type gallium nitride layer 5 has a first groove 6 and a second groove 7 formed concavely and deep into the N-type gallium nitride layer 2, the first groove The periphery of 6 is a first protrusion 8, and the inner ring of the first groove 6 is a plurality of second protrusions 9, and the plurality of second protrusions 9 are separated by the second groove 7; the P-type nitride There is an insulating layer 10 on the gallium layer 5, the insulating layer 10 has a first opening 11 at the first groove 6, and the insulating layer 10 has a second opening 12 at the second protrusion 9; There is an N electrode layer 13 at the first opening 11, which is in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com