Miniature LED chip detection structure and preparation method thereof

A technology for LED chips and detection structures, which is applied in semiconductor/solid-state device testing/measurement, electrical components, electric solid-state devices, etc. Crystal points are not on the same plane, etc., to achieve the effect of improving the quality of the eutectic

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

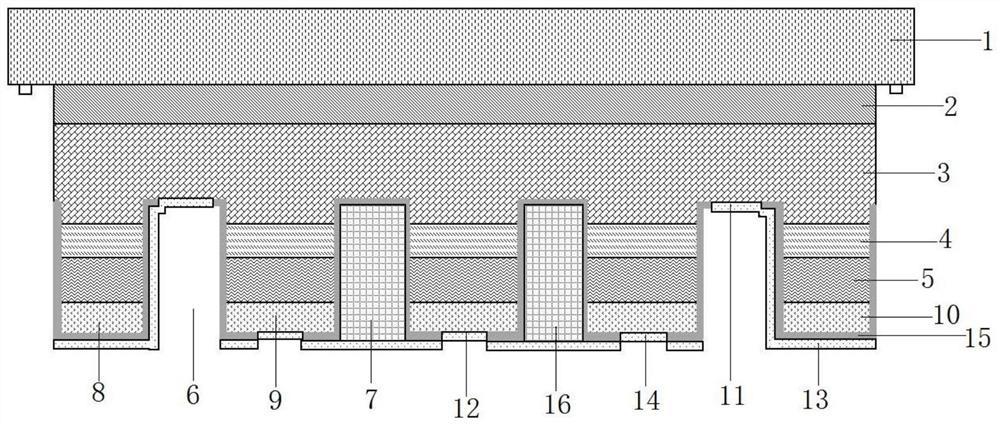

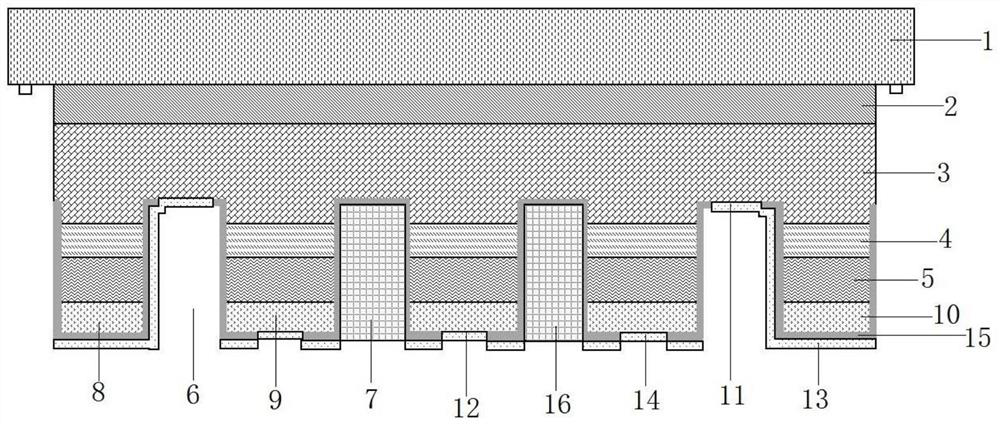

[0067] refer to figure 1 . The detection structure of the micro-LED chip in this embodiment is a common cathode and common anode structure, which includes a substrate 1, and a U-type gallium nitride layer 2 extending outward from one side of the substrate 1, and an N-type gallium nitride layer. Gallium layer 3, light-emitting layer 4 and P-type gallium nitride layer 5; the surface of the P-type gallium nitride layer 5 has a concave first groove 6 and a second groove formed deep into the N-type gallium nitride layer 2 Groove 7, the periphery of the first groove 6 is a first protrusion 8, the inner circle of the first groove 6 is a plurality of second protrusions 9, and a plurality of second protrusions 9 pass through the second concave grooves 7 intervals; the P-type gallium nitride layer 5 has an insulating layer 10, the insulating layer 10 has a first opening 11 at the first groove 6, and the insulating layer 10 has a first opening 11 at the second convex There is a second ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com