Cable bridge for electromechanical equipment

A technology for cable trays and electromechanical equipment, which is applied in the field of cable trays for electromechanical equipment, which can solve problems such as potential safety hazards, easy spread, and low safety performance, and achieve the effects of good safety, preventing fire from spreading, and improving safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

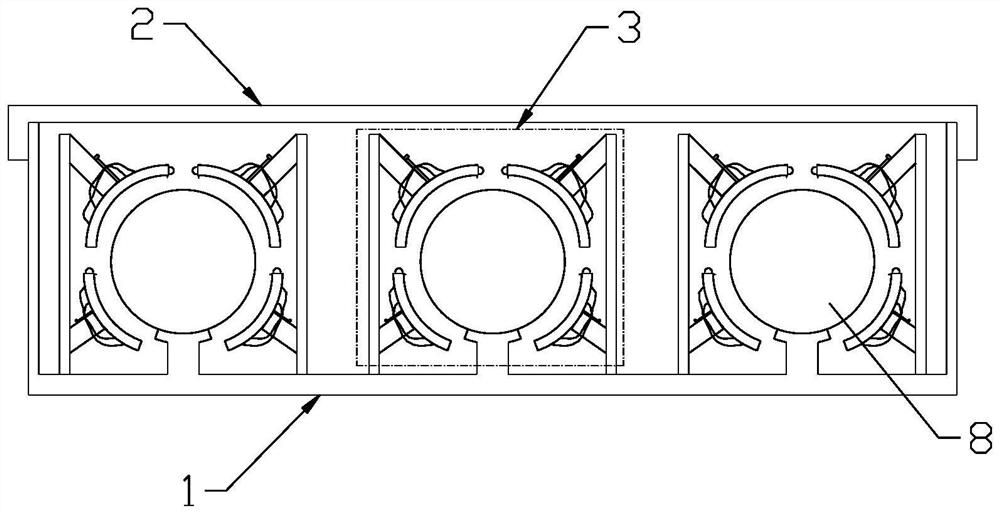

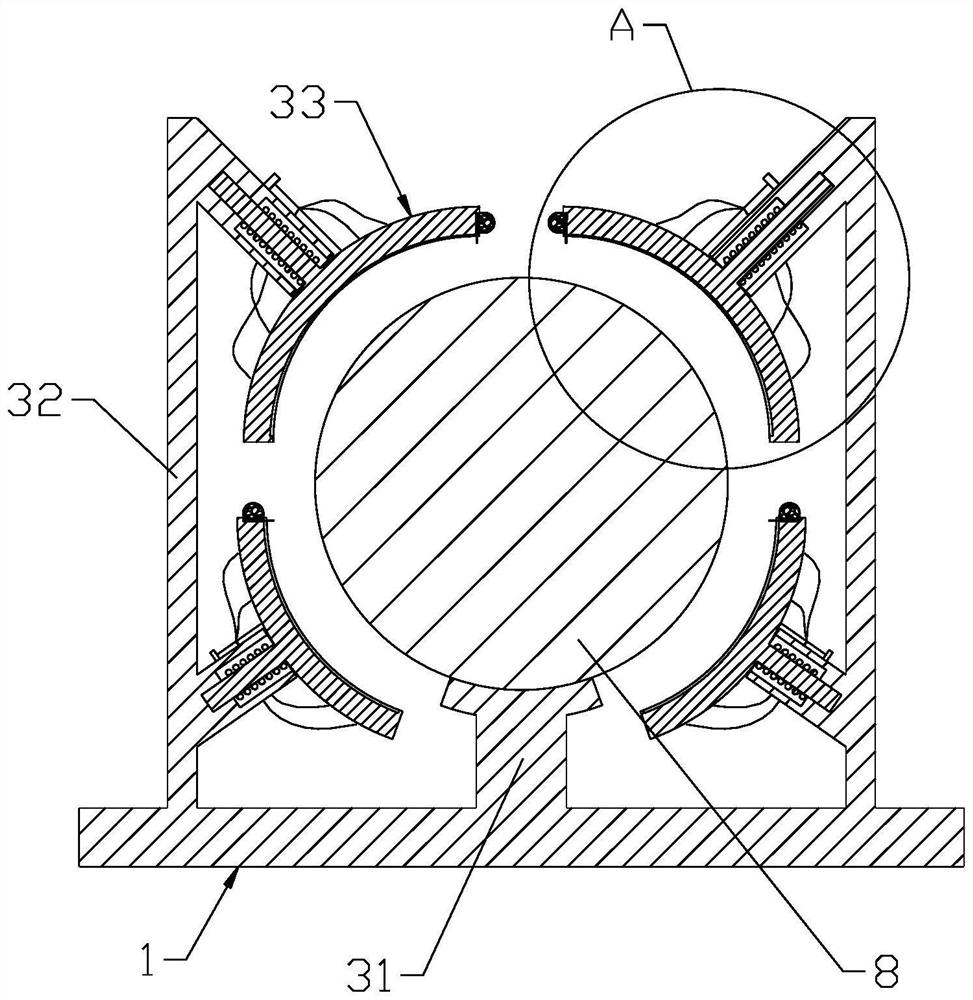

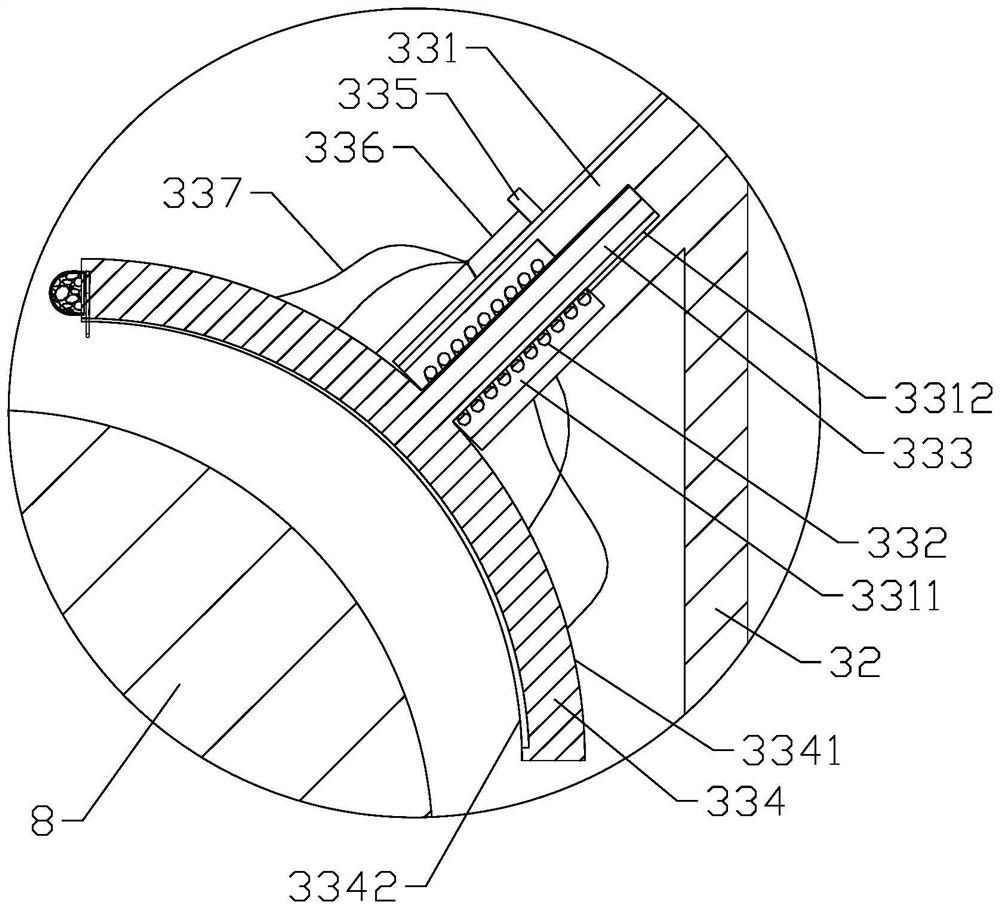

[0033] Embodiment one: if Figure 1-4As shown, a cable tray for electromechanical equipment includes a cable tray 1 and a protective cover 2, the protective cover 2 is covered on the cable tray 1, and the cable tray 1 is provided with at least two paving units for passing cables 8 3. The paving unit 3 includes a base 31 for supporting the cable 8 and two side plates 32, the two side plates 32 are distributed on both sides of the base 31, and two fire extinguishing assemblies 33 distributed up and down are arranged on the side plates 32 The fire extinguishing assembly 33 includes a mounting rod 331, a compression spring 332, a sliding rod 333, an arc plate 334, a positioning block 335, a thermal fuse 336 and a plurality of heat conducting wires 337, and one end of the mounting rod 331 is fixedly connected to the side plate 32, and the installation The other end of the rod 331 faces the position where the cable 8 is located. The other end of the mounting rod 331 is provided with...

Embodiment 2

[0041] Embodiment two: if Figure 7-11 As shown, the remaining parts are the same as in Embodiment 1, except that the two ends of the arc-shaped plate 334 along the circumferential direction are defined as the first end face 3344 and the second end face 3345, and the height of the first end face 3344 is higher than that of the second end face. At the height of the end face 3345, the first end face 3344 is provided with a first accommodating groove 3346, the first accommodating groove 3346 is provided with a fire extinguishing agent 4, and the inner concave arc surface 3342 of the arc plate 334 is provided with a second accommodating Groove 3347, the groove bottom of the second accommodating groove 3347 is provided with the groove 3348 that communicates with the first accommodating groove 3346, and the groove 3348 is located at the highest point of the second accommodating groove 3347, and the elastic member 5 is arranged in the groove 3348 And the slide plate 6, the slide plat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com