Grinding roller based on bionic diamond drill bit

A diamond drill bit and grinding roller technology, applied in the field of grinding rollers, can solve the problems of low replacement efficiency, affecting the normal use of equipment, etc., and achieve the effects of convenient disassembly and maintenance, reduction of labor cost and time cost, and easy installation and disassembly.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

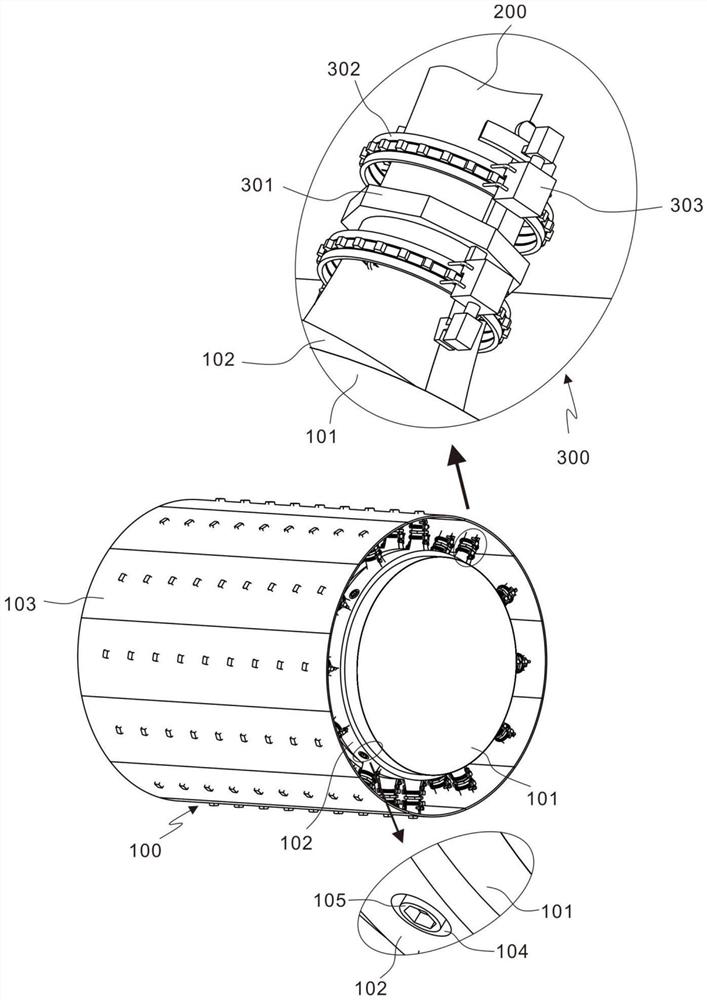

[0026] refer to figure 1 , 2 , is the first embodiment of the present invention, which provides a grinding roller based on a bionic diamond drill bit, including a grinding roller mechanism 100, and,

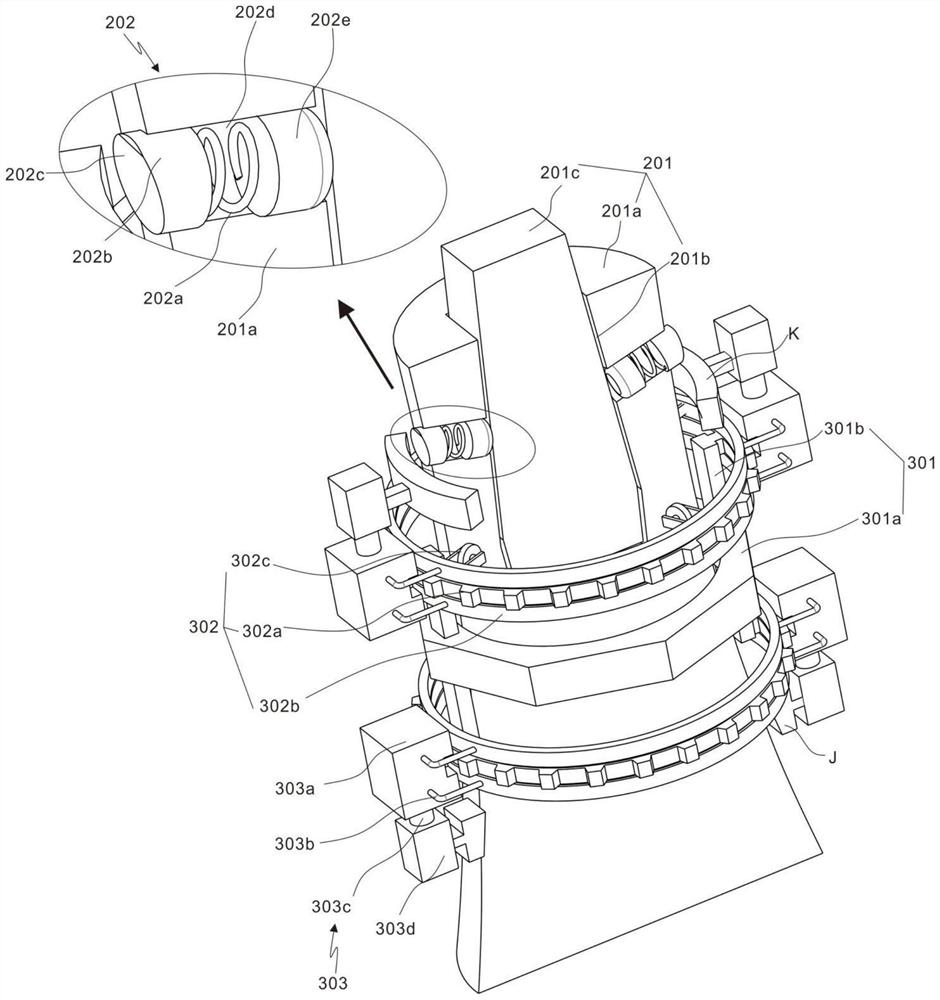

[0027] The drill bit installation module 200, the drill bit installation module 200 is movably connected with the grinding roller mechanism 100, the drill bit installation module 200 is arranged at the grinding roller mechanism 100, and is used to install and fix the diamond bit, and the grinding roller mechanism 100 is connected to the driving equipment, and the operation process Among them, the grinding operation is carried out through a diamond drill bit. The hardness of the diamond drill bit is higher than that of the grinding roller, so that the grinding effect is better and the service life of the grinding roller is effectively improved. The drill bit installation module 200 includes an installation assembly 201 and an extrusion assembly 202. It is movably connected with t...

Embodiment 2

[0030] refer to Figure 1~3 , is the second embodiment of the present invention, which is based on the previous embodiment.

[0031] The grinding roller mechanism 100 includes an inner grinding roller main body 101, a mounting ring 102 and an outer grinding roller arc plate 103, the mounting ring 102 is linearly arranged on the surface of the inner grinding roller main body 101, and the outer grinding roller arc plates 103 are arranged in a circular array on the inner grinding roller On the outer side of the surface of the main body 101, the outer grinding roller arc plates 103 are spliced to form an arc-shaped cylinder. The outer grinding roller arc plates 103 are installed independently. When it is necessary to disassemble and replace the drill bit for maintenance, just disassemble the corresponding outer grinding roller arc plate 103 For replacement, there is no need to disassemble the whole device, and the installation ring 102 is connected to the installation assembly 2...

Embodiment 3

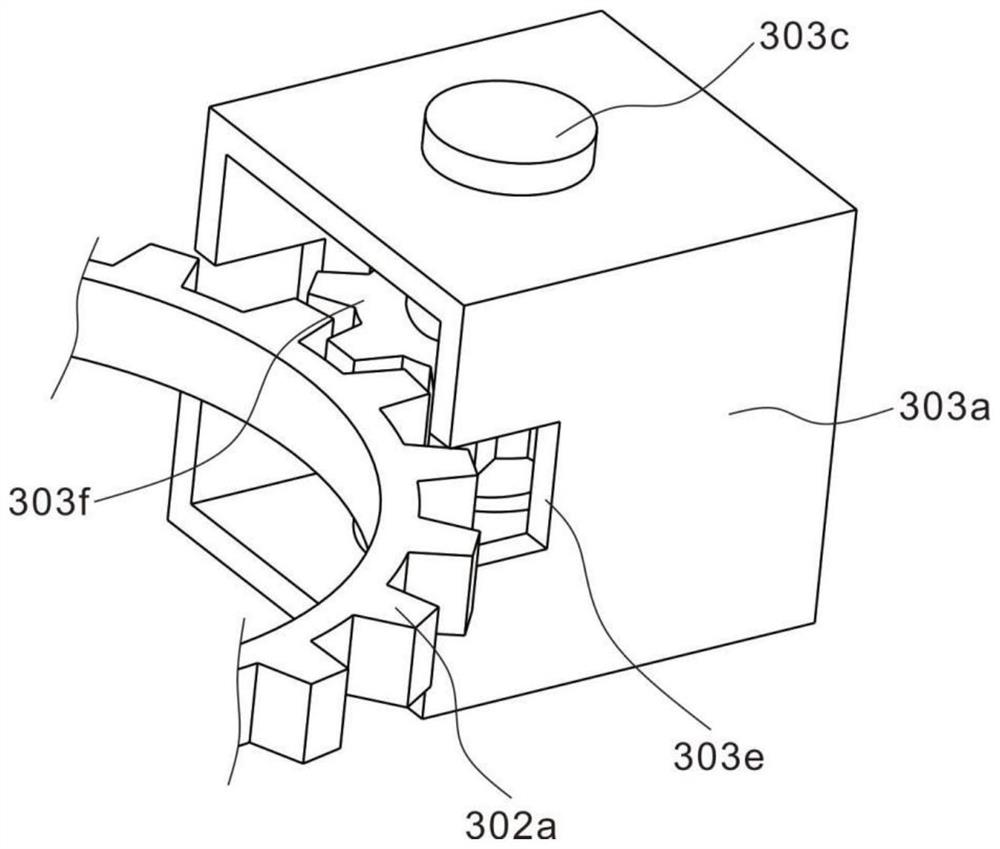

[0038] refer to Figure 1~3 , is the third embodiment of the present invention, which is based on the above two embodiments.

[0039] The extension and compression assembly 303 also includes a threaded block 303d. The inner wall of the threaded block 303d is threadedly connected with the outer surface of the screw rod 303c. The bump J and the arc-shaped pressing plate K move to make them press and fix. When the screw rod 303c rotates, the threaded block 303d is driven to rotate, and the trapezoidal bump J and the arc-shaped pressing plate K are driven by the rotation of the threaded block 303d. Rotate, the trapezoidal projection J and the arc-shaped pressing plate K rotate and stop after contacting the surface of the mounting block 201a, and the rotation of the screw rod 303c continues, so that the threaded block 303d changes from rotation to movement, thereby driving the trapezoidal projection J and the arc-shaped pressing plate K moves, the trapezoidal projection J moves to...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap