Vehicle radar mounting structure and assembling method

A technology for installation structure and radar, applied in superstructure, superstructure sub-assembly, motor vehicles, etc., can solve the problems of poor versatility and stability, achieve good structural stability, reduce design and manufacturing costs, and improve installation positioning accuracy Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

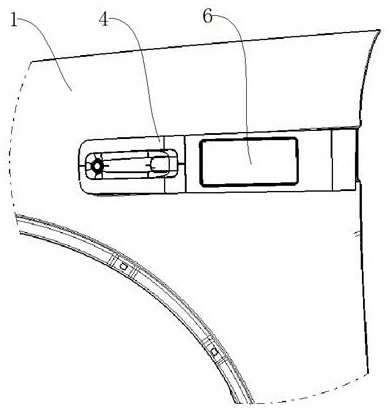

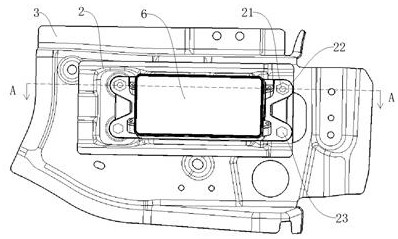

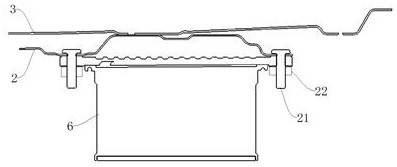

[0044] See Figure 1-Figure 3 with Figure 5 , a vehicle radar mounting structure, comprising a fender 1 fixedly connected to the outer surface of the car body 3, the fender 1 is provided with a mounting hole 11, and an adapter bracket 2 is provided in the mounting hole 11, and the adapter The bracket 2 is fixedly connected with the vehicle body 3, and the side of the adapter bracket 2 away from the vehicle body 3 is fixedly provided with two fixed studs 21, and the free ends of the fixed studs 21 extend outward along the width direction of the vehicle body 3;

[0045]The vehicle radar 6 is installed in the installation hole 11, and the detection end of the vehicle radar 6 is arranged outwardly along the width direction of the vehicle body 3. The vehicle radar 6 is penetrated with two fixing holes, and the two fixing studs 21 are one-to-one. Located in the two fixing holes; the fixing stud 21 is threadedly connected with a locking nut 22, the vehicle radar 6 is located betwee...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com