Multifunctional centrifugal fan and operation method

A centrifugal fan and centrifugal fan technology, which are applied in the cleaning methods, chemical instruments and methods, cleaning methods and utensils using gas flow, etc., can solve the problems of no air supply and dust removal, pollution of the workshop environment, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

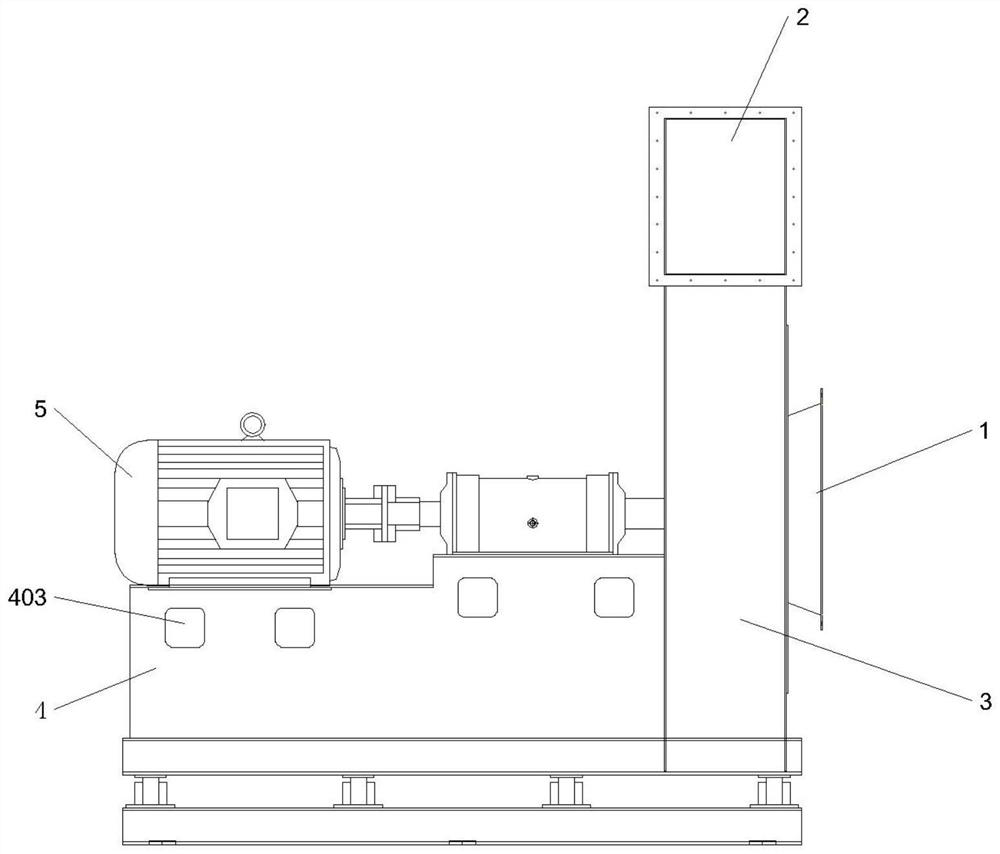

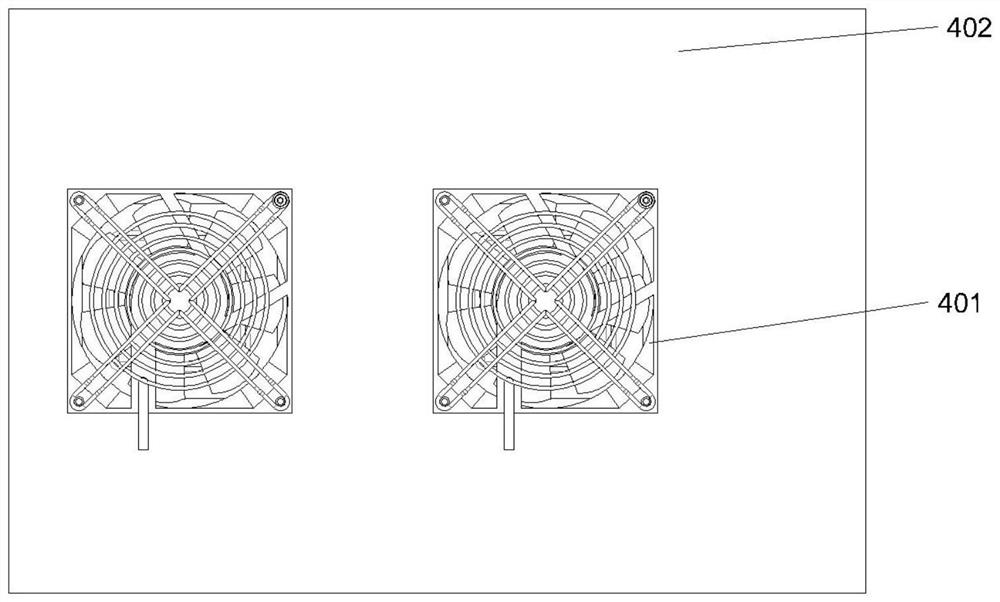

[0034] Such as Figure 1 ~ Figure 2 As shown, the present invention provides a multifunctional centrifugal fan, including a centrifugal fan 3, the centrifugal fan 3 is provided with an air outlet 2 and an air inlet 1, and the braking element 5 provided on the centrifugal fan 3 is installed on heat sink 4.

[0035] The heat dissipation device 4 includes a heat dissipation fan 401, the heat dissipation fan 401 is installed on the heat dissipation wind cover 402, and the side of the heat dissipation wind cover 402 is uniformly provided with heat dissipation holes 403, and the braking element 5 is installed on the heat dissipation wind cover 402 And the connection position is provided with ventilation holes.

[0036] The device can help the brake element 5 provided in the centrifugal fan 3 to dissipate heat.

Embodiment 2

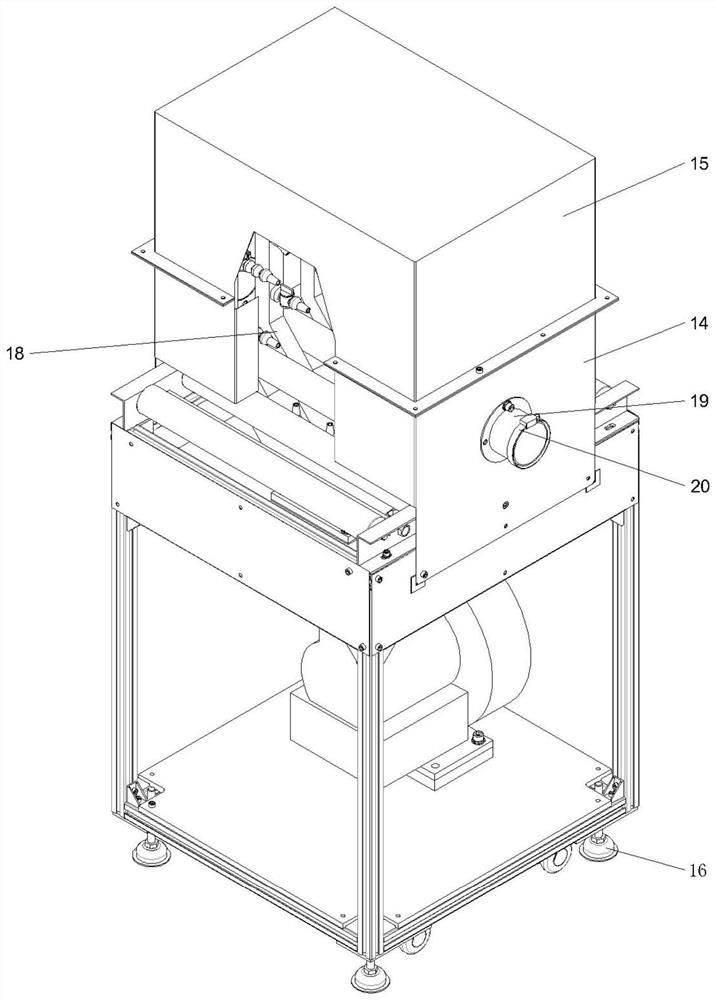

[0038] Such as Figure 3 ~ Figure 5 As shown, the centrifugal fan also includes a frame 6, the frame 6 is assembled from aluminum profiles, the frame 6 is provided with a partition 17, and a partition is placed on the partition 17, and the centrifugal The blower fan 3 is placed on the bottom of the frame 6, the connecting pipe 8 is installed on the bottom surface of the partition, and the connecting pipe 8 is connected with the centrifugal fan 3 through the ventilation pipe 7, and the omnidirectional air supply device is installed on the top surface of the partition and is located on the connecting pipe. 8 directly above, and the connection position between the omni-directional air supply device and the partition is a through hole.

[0039] The omni-directional air supply device comprises an annular square tube 9 evenly installed on the partition through a square tube mounting seat 13, and the connection position between the annular square tube 9 and the partition is a through...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com