Cigar rolling device

A technology of cigar rolls and driving devices, which is applied in the manufacture of cigars, applications, tobacco, etc. It can solve the problems of box flatness difference, poor aesthetics, and affect customers' purchase experience, and achieve the effect of improving consistency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The core of the present invention is to disclose a cigar rolling device to improve the consistency of the size of the same batch of cigars.

[0040] In order to enable those in the technical field to better understand the present invention, the following embodiments of the present invention are described with reference to the accompanying drawings. Further, the embodiments shown below do not have any restrictive effect on the content of the invention recorded in the claims. Further, the entire content of the composition expressed in the following embodiments is not limited to the solution necessary as a solution to the invention recorded in the claims.

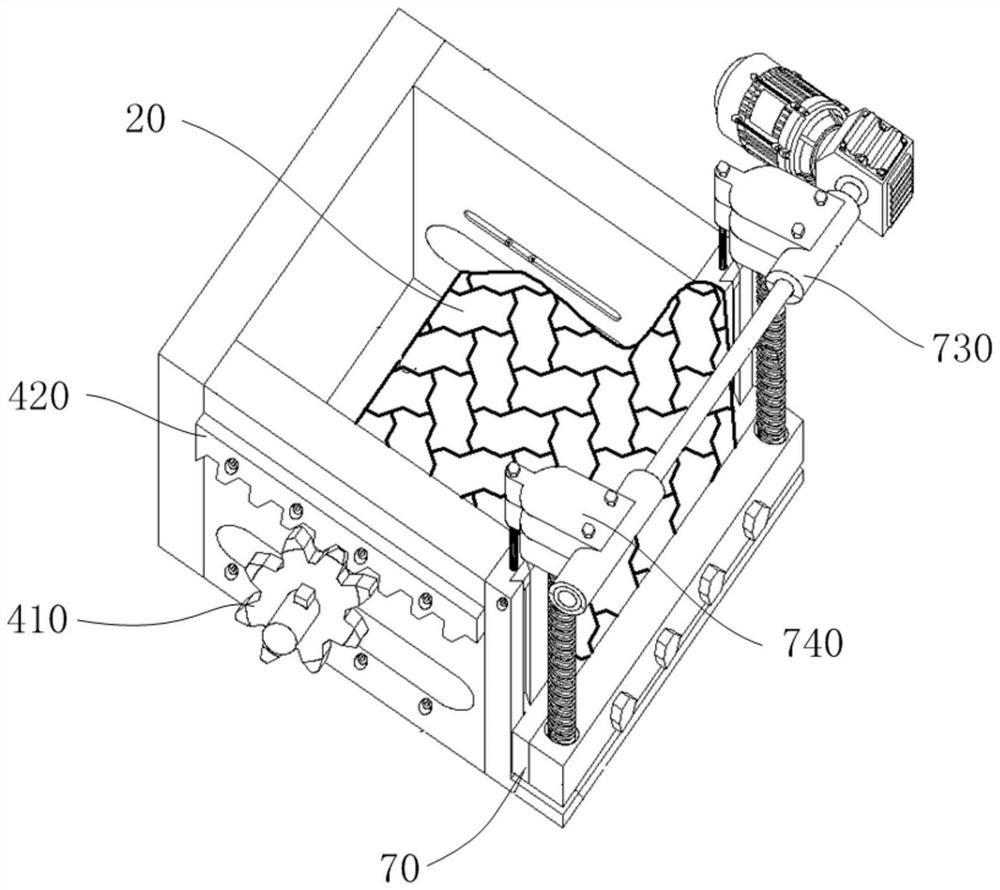

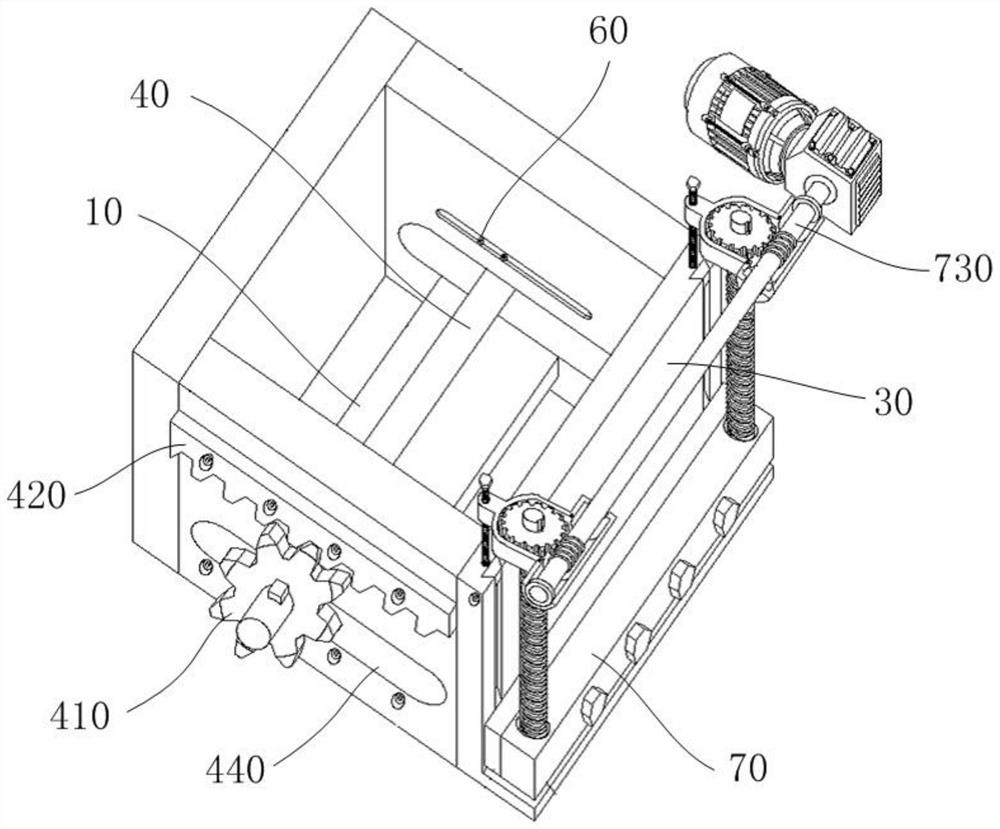

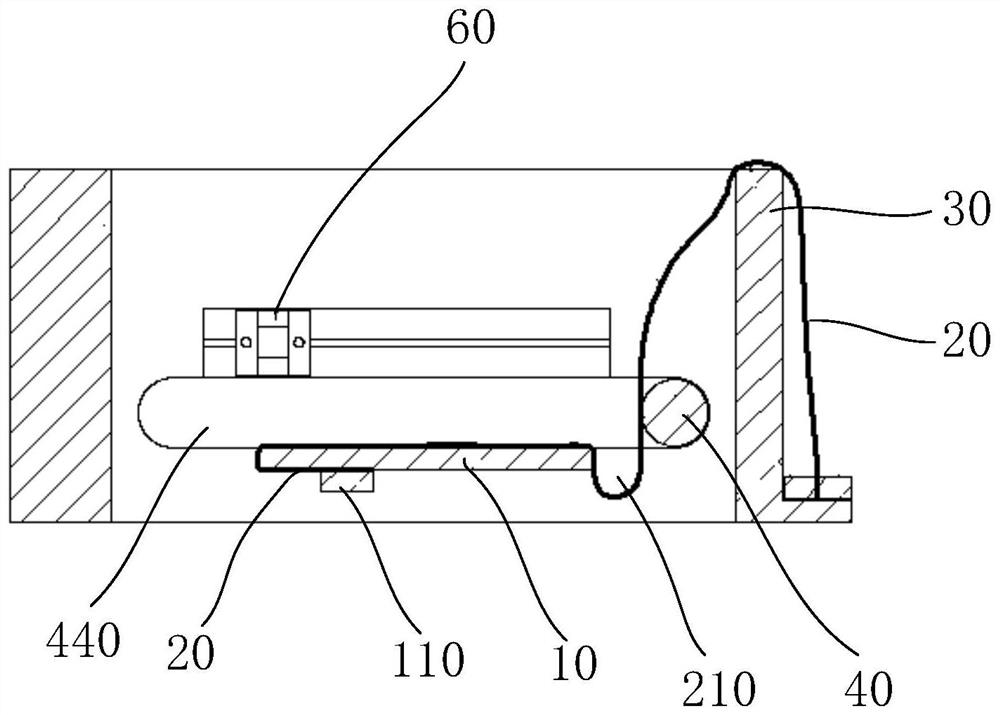

[0041] as Figure 1 、 Figure 2 、 Figure 3 and Figure 5As shown, the cigar rolling apparatus provided by the present invention, comprising a load plate 10, a mesh blanket 20, a tailgate 30, a rolling shaft 40 and a first drive device 50, wherein the mesh blanket 20 is laid on the first surface of the load-bearing plate 10, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com