Explosion-proof evaluation system for power equipment

A technology for evaluating systems and power equipment, applied in signal transmission systems, instruments, measuring devices, etc., can solve the problems of large differences in shape and volume of electrical equipment, large differences in actual use locations, uneven gas distribution, etc., and achieve installation swing Simple and convenient to put, safe and convenient to use, simple to adjust

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

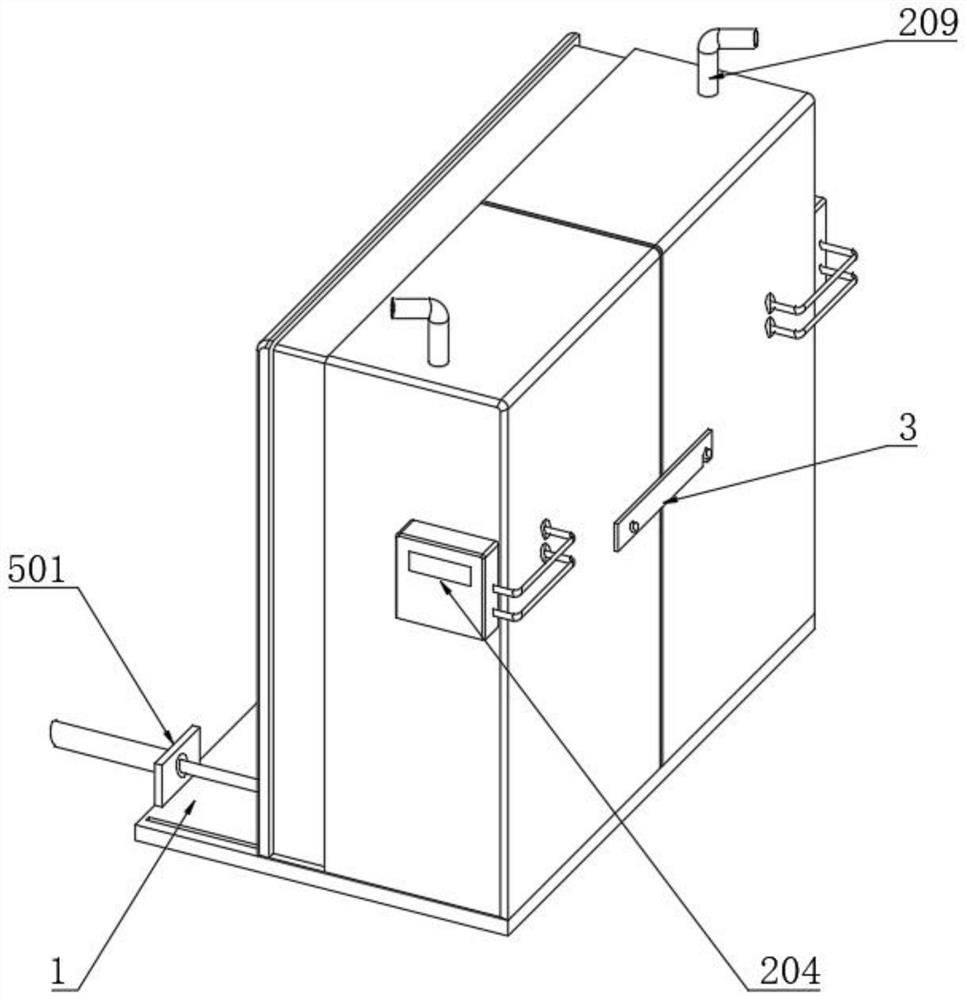

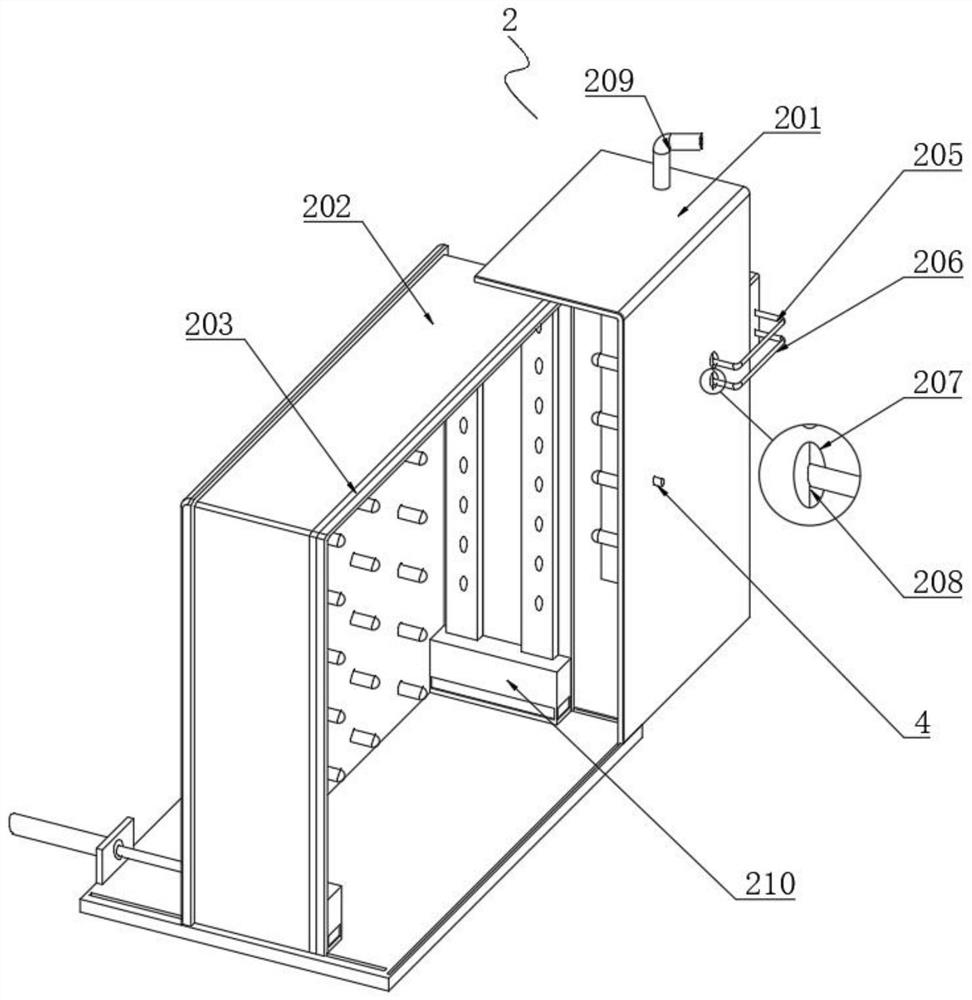

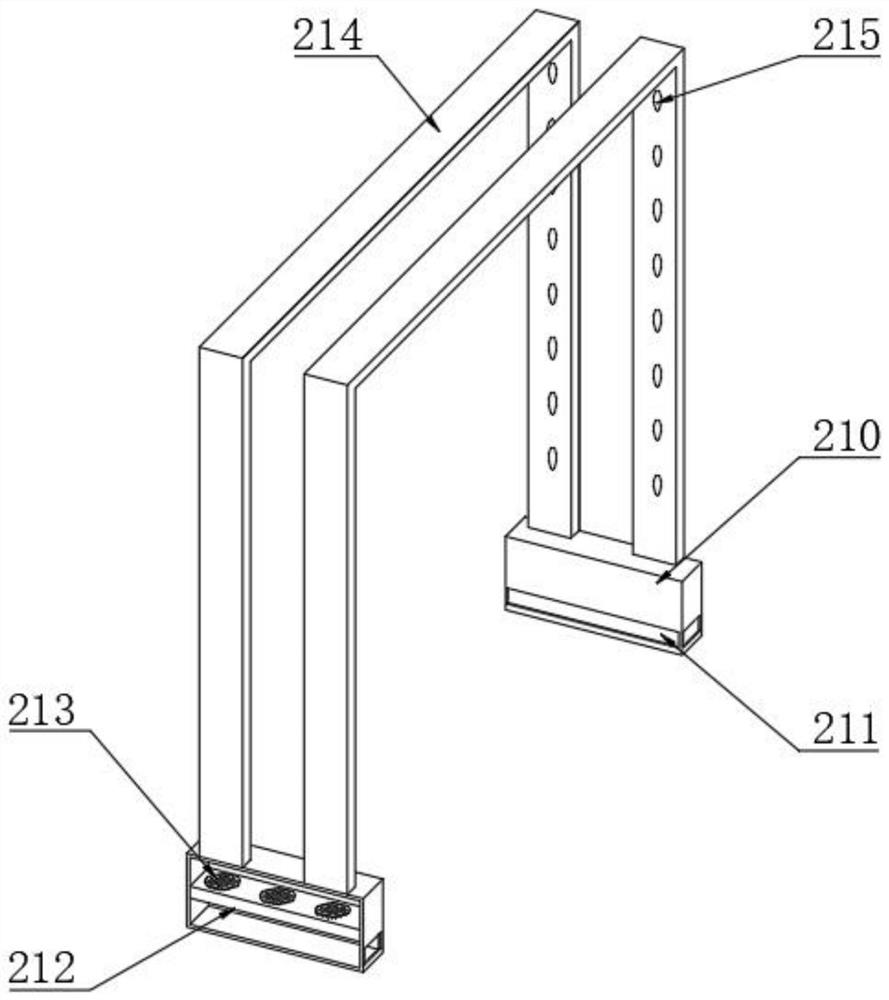

[0035] Example: such as Figure 1-5 As shown, the present invention provides a technical solution for an explosion-proof evaluation system of electric equipment, including a bottom plate 1, an explosion-proof detection component 2 is installed on the top surface of the bottom plate 1, and the explosion-proof detection component 2 includes a sliding side cover 201, an adjustment cover 202, and a rubber strip 203 , detection box 204, outer probe line 205, inner probe line 206, threading hole 207, semicircle sealing block 208, air inlet pipe 209, air inlet box 210, air inlet 211, dividing plate 212, fan 213, 冂 type pipe 214 and Air outlet 215;

[0036] The bottom ends of the two sliding side covers 201 are symmetrically slid and embedded on both sides of the bottom plate 1, the middle part of one sliding side cover 201 is equipped with a clamping plate 3 through a rotating shaft, and a clamping post 4 is installed at a position corresponding to the clamping plate 3 of one sliding...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com