Sleeve deformation area detection system based on machine vision

A machine vision, deformation zone technology, applied in instruments, measuring devices, devices using optical methods, etc., can solve the problems of large workload, long time, low efficiency, etc., to solve the problem of large workload, improve functionalization and intelligence the effect of

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

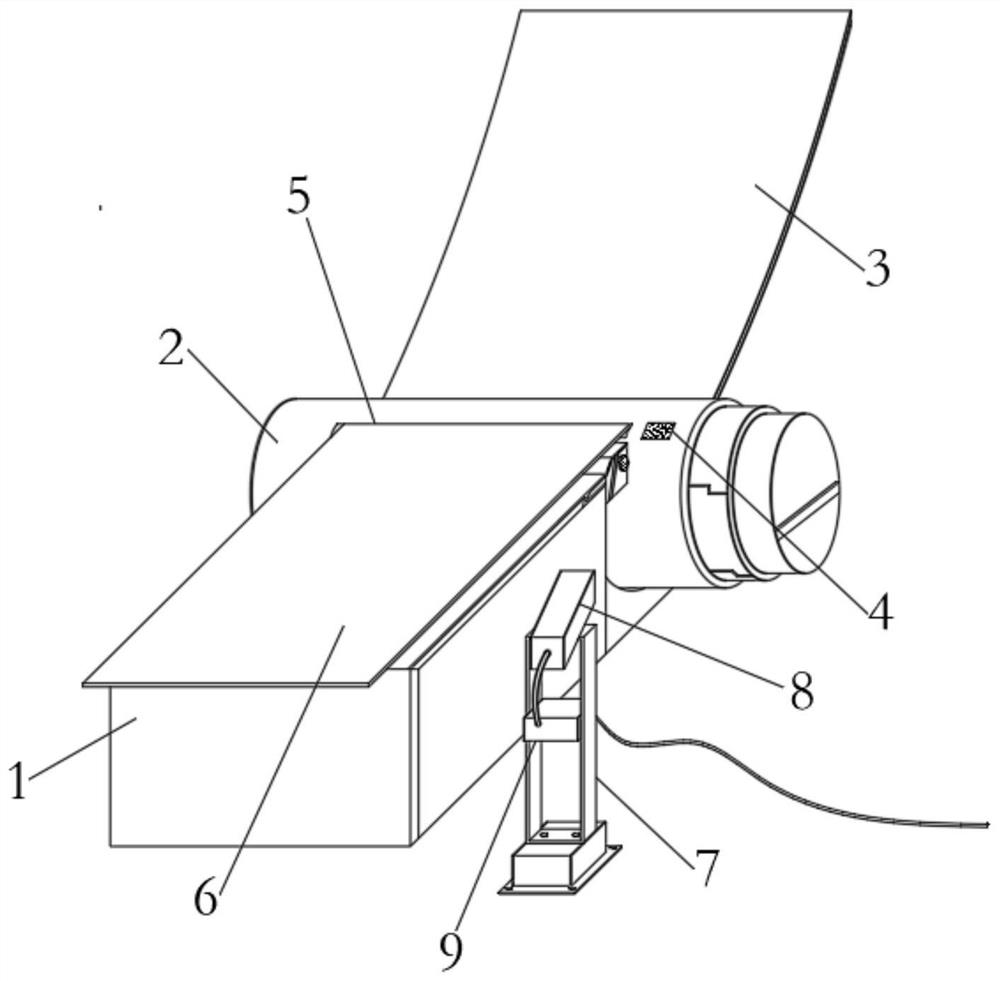

[0019] see Figure 1-3 , the present invention provides a kind of technical scheme:

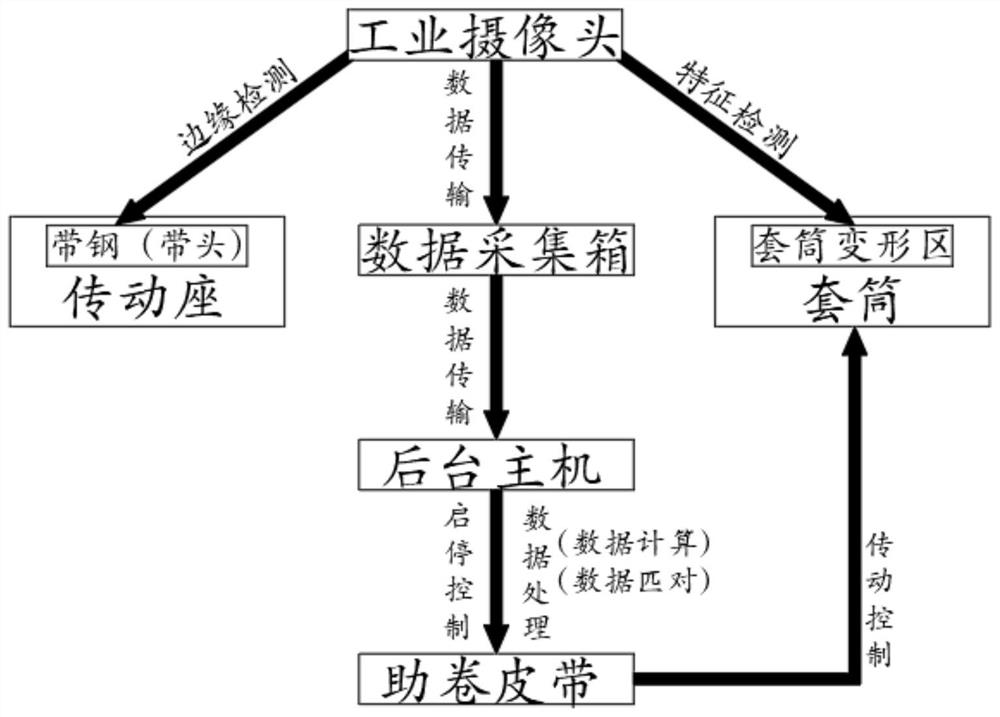

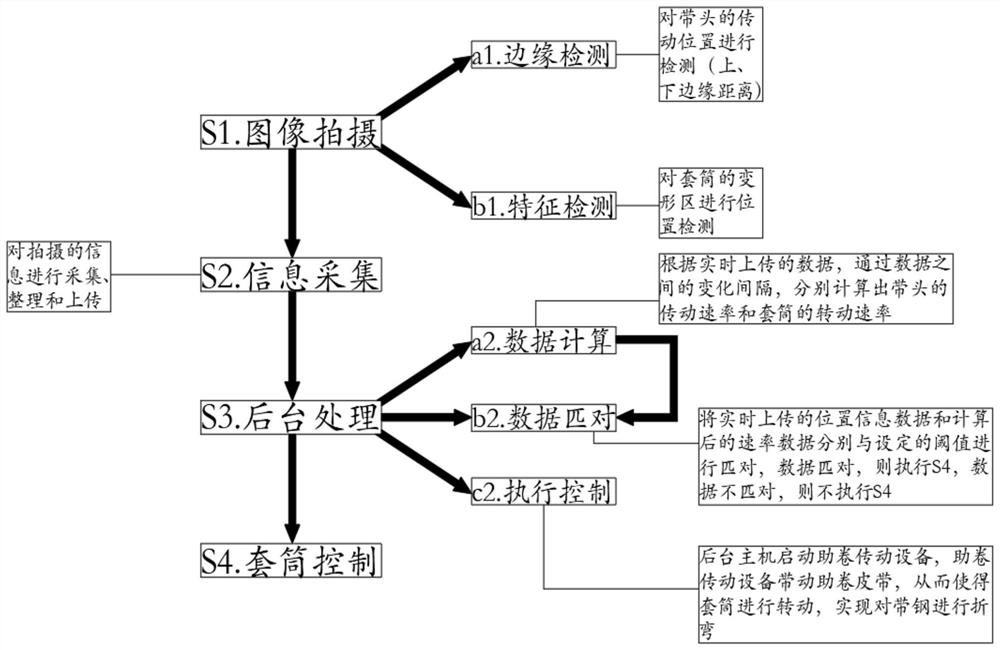

[0020] A detection system for sleeve deformation zone based on machine vision, including sleeve equipment, detection equipment and background equipment, the sleeve equipment includes a transmission base 1, a sleeve 2 and a winding belt 3, and the transmission base 1 is provided with a strip steel 6. The sleeve 2 is provided with a sleeve deformation area 4 and a roll fold 5. The sleeve deformation area 4 is located on one side of the roll fold 5. One end of the roll-assisting belt 3 is connected to the transmission end of the sleeve 2, and the other end is fixed to the auxiliary belt. On the drive roller of the roll transmission equipment, the detection equipment includes a bracket 7, an industrial camera 8 and a data acquisition box 9. The industrial camera 8 and the data acquisition box 9 are both fixed on the bracket 7. The background device is the background host, and the industrial camer...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com