Water supply system and control method for mobile capsule coffee machine

A technology for water supply system and coffee machine, which is applied to beverage preparation devices, kitchen utensils, home utensils, etc., can solve the problems of limited heating capacity, inability to maintain heat preservation function, etc., and achieve the effect of maintaining heat preservation function

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

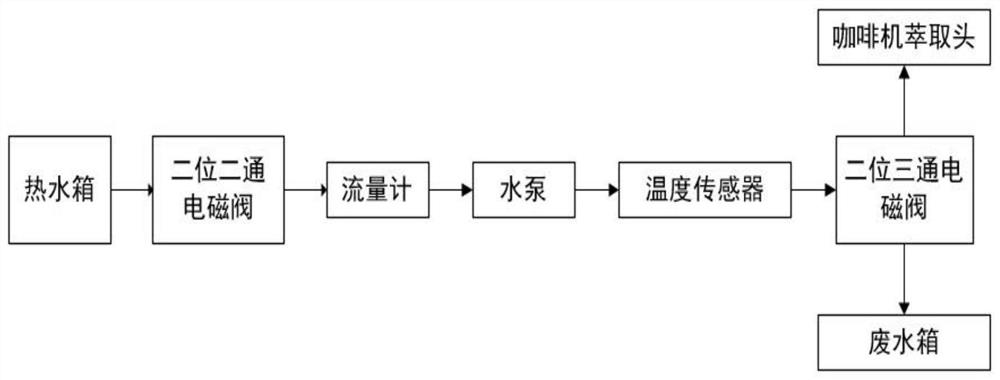

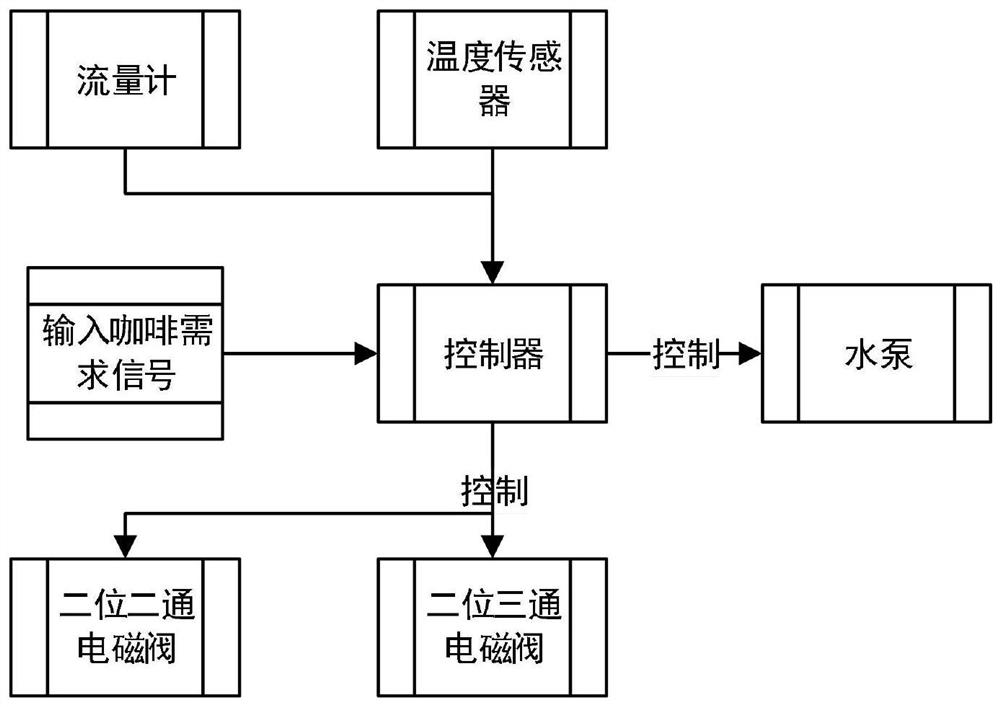

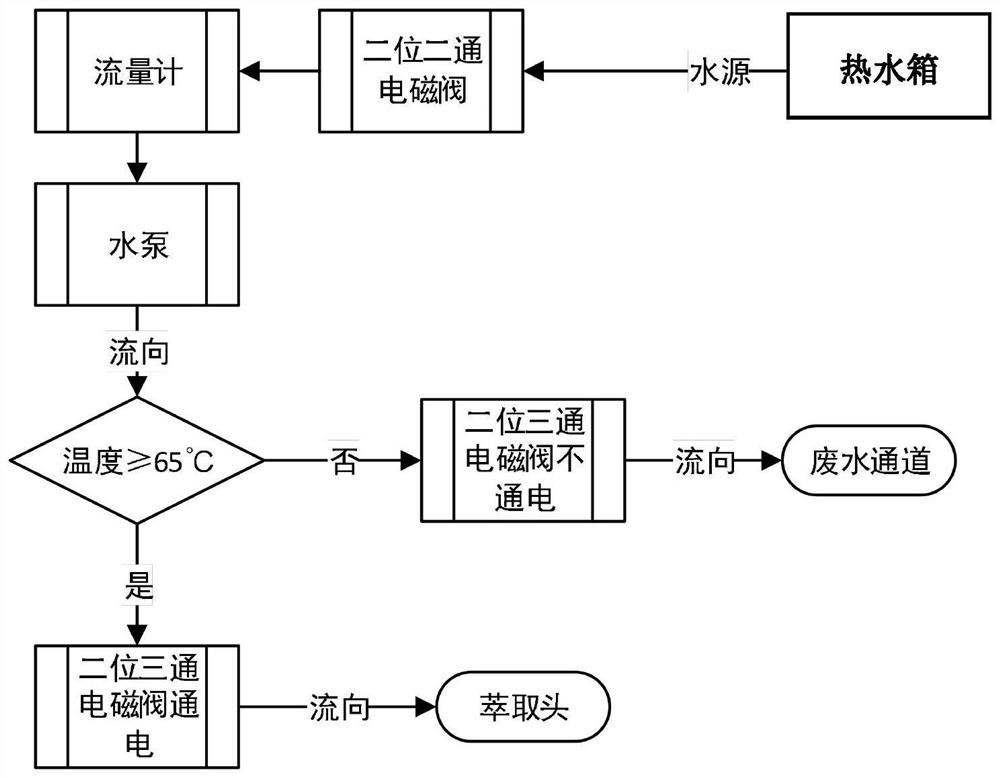

[0022] The present invention adopts the following technical solutions: provide a mobile capsule coffee machine water supply system, including a mobile capsule coffee machine body and a water supply system, such as figure 1 As shown, the water supply system includes a hot water tank. The hot water tank has its own water level sensor. When the water level in the hot water tank is lower than the set height, the capsule coffee machine is moved back to the charging position for water replenishment and heating. The solenoid valve includes a two-position, two-way solenoid valve and a two-position, three-way solenoid valve. The solenoid valve is used to switch the liquid circuit on and off or change the direction of the liquid flow. The input port of the two-position, two-way solenoid valve is connected to a hot water The output port is connected to the flow meter; the input port of the two-position three-way solenoid valve is connected to a temperature sensor, and the first output por...

Embodiment approach 2

[0026] Provide another mobile capsule coffee machine water supply heating system, including the mobile capsule coffee machine body and water supply heating system, such as Figure 4 As shown, the water supply heating system includes a hot water tank. The hot water tank has its own water level sensor. When the water level in the hot water tank is lower than the set height, the capsule coffee machine is moved back to the charging position to replenish water. Solenoid valve, the solenoid valve includes two-position two-way solenoid valve and two-position three-way solenoid valve, the input port of the two-position two-way solenoid valve is connected to a hot water tank, and the output port is connected to a flowmeter; the two-position three-way The input port of the solenoid valve is connected to a temperature sensor, and the first output port is connected to the extraction head of the capsule coffee machine body. Flow meters, water pumps, temperature sensors and pipelines, and h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com