Buffer structure for lifting strength training equipment

A technology of training equipment and cushioning structure, applied in the field of training equipment, can solve problems such as easy vibration, rope wear, breakage, etc., and achieve the effect of avoiding damage to equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

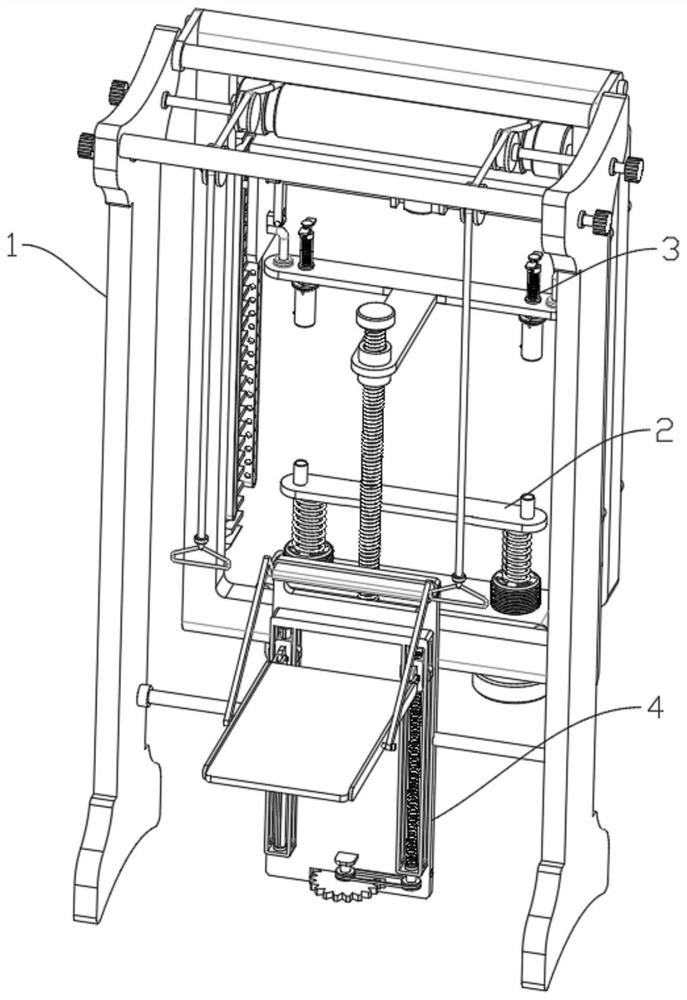

[0034] Please refer to figure 2 As shown, a buffer structure for lifting strength training equipment includes a gantry frame 1, the rear end of the gantry frame 1 is provided with an anti-fall pulling mechanism 2, and the left end of the anti-fall pulling mechanism 2 is provided with a drop buffering lever mechanism 3 , The lower end of the anti-fall pulling mechanism 2 is provided with a standing and sitting training adjustment mechanism 4 .

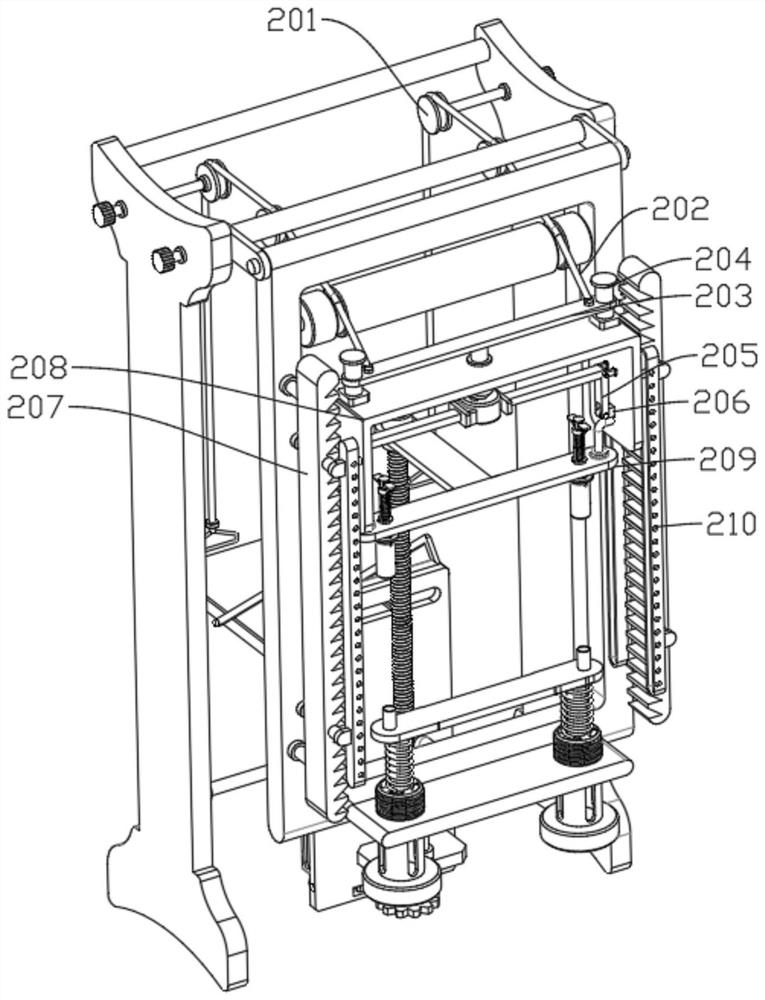

[0035]Preferably, the anti-fall pulling mechanism 2 includes a positioning roller 201, a pulling rope 202, a spring long plate 203, a dynamic positioning rod 204, a bending rod 205, a slope positioning rod 206, a plane sawtooth plate 207, and the inner walls of the left and right ends of the gantry 1 A positioning roller mechanism 201 is rotatably connected to each other, and a pull rope 202 is slidably connected to the outer surface of one end of the positioning roller 201. A groove shell 208 is fixedly connected to the lower end of ...

Embodiment 2

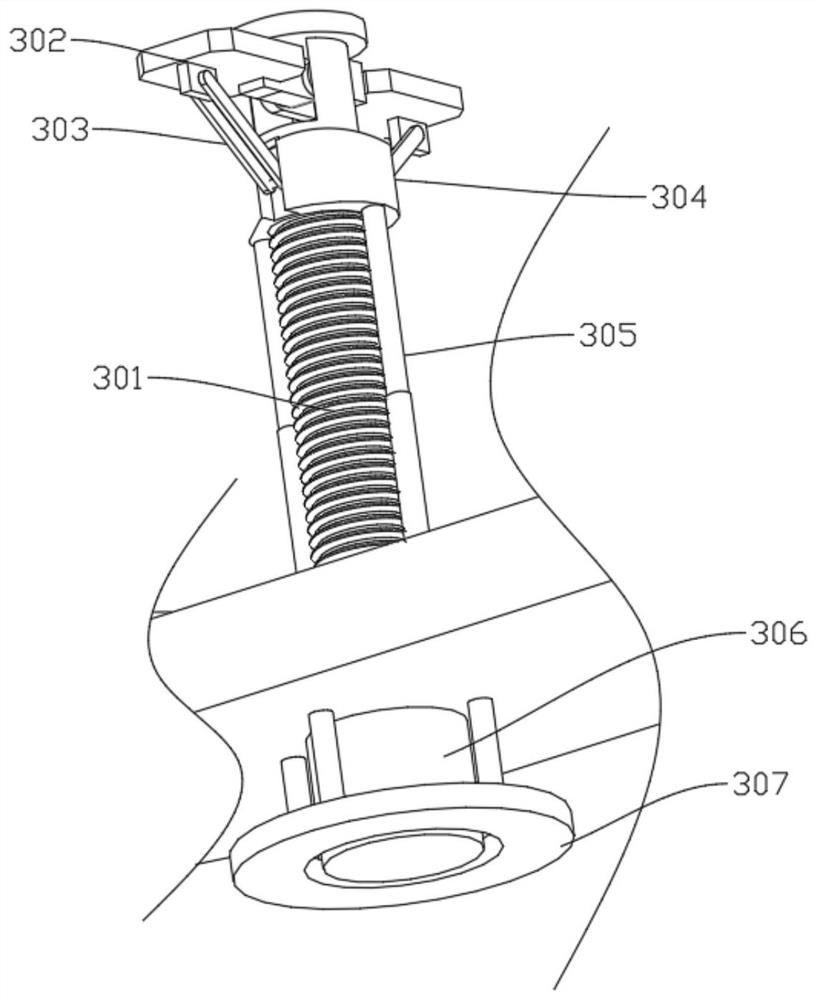

[0038] Please refer to image 3 Figure 4 and Figure 5 and Image 6 and Figure 7 As shown, the drop buffer opening mechanism 3 includes a short screw 301, a grid baffle 302, a support rod 303, a power internal thread sleeve 304, a telescopic rod 305, a turning plate 306, a positioning ring 307, and the left and right ends of the counterweight plate 209 are fixed. A short screw 301 is connected, the upper end of the short screw 301 is rotatably connected with a grid baffle 302, the front and rear ends of the grid baffle 302 are rotatably connected with a support rod 303, and the lower end of the support rod 303 is rotatably connected with a power internal thread sleeve 304, a power internal thread sleeve The lower end of 304 is fixedly connected with a telescopic rod 305, the lower end of the telescopic rod 305 is fixedly connected with a rotating plate 306, the lower end of the rotating plate 306 is rotatably connected to the left and right ends of the counterweight plate...

Embodiment 3

[0041] Please refer to Figure 8 Figure 9 and Figure 10 and Figure 11 As shown, the standing and sitting training adjustment mechanism 4 includes a power threaded rod 402, a drive positioning plate 403, a first groove opening 404, a second groove rod 405, a first gear 406, a second gear 407, and the left end of the weight plate 209. The inner thread driving plate 401 is fixedly connected, the left end of the inner thread driving plate 401 is threadedly connected with a power threaded rod 402, the lower end of the power threaded rod 402 is rotatably connected with a driving positioning plate 403, and the lower end of the driving positioning plate 403 is provided with a first groove opening 404, The lower end of the first groove opening 404 is provided with a second groove rod 405, the lower end of the second groove rod 405 is fixedly connected with a first gear 406, the left end of the first gear 406 is engaged with a second gear 407, and the upper end of the second gear 4...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com