Teaching robot moving device with anti-collision function

A teaching robot and mobile device technology, applied to teaching models, instruments, manipulators, etc., can solve problems such as teaching accidents, lack of educational resources, and easy collision of intelligent robotic arms with students, so as to ensure safety, prevent failure to avoid, and ensure teaching safe effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

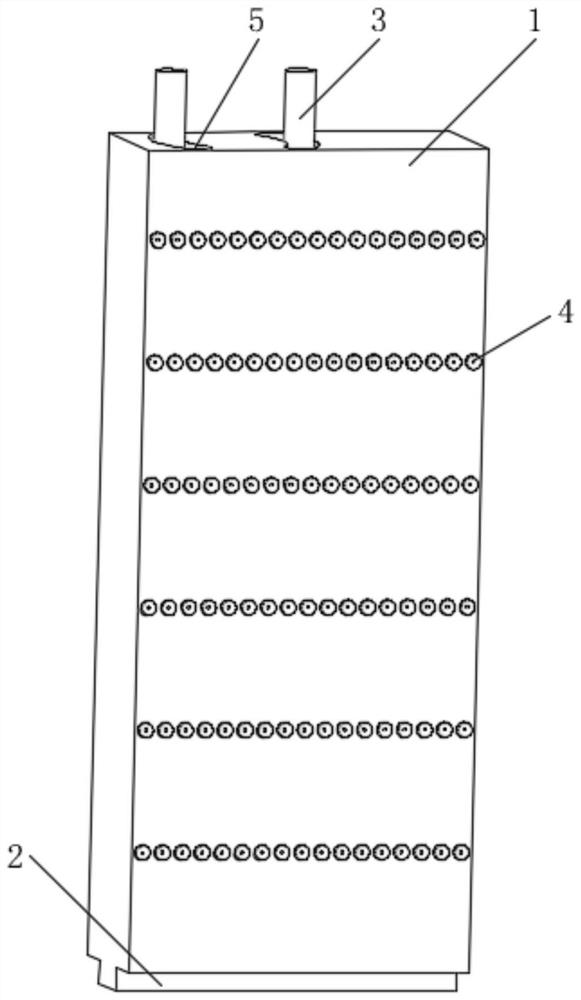

[0032] see Figure 1-2 , a teaching robot mobile device with anti-collision function, including a mechanical arm 1, the bottom of the mechanical arm 1 is fixedly connected to the clamping piece installation port 2, the top of the mechanical arm 1 is installed with a power rod 3, there are two power rods 3, one The root is located at the center of the top of the robotic arm 1, and the other is located on the side of the top of the robotic arm 1. The power rod 3 is divided into two upper and lower sections, and the two sections are connected by bearings;

[0033] A sensing mechanism 4 for predicting collision is arranged on the outer surface of the robotic arm 1 that is perpendicular to its own running track;

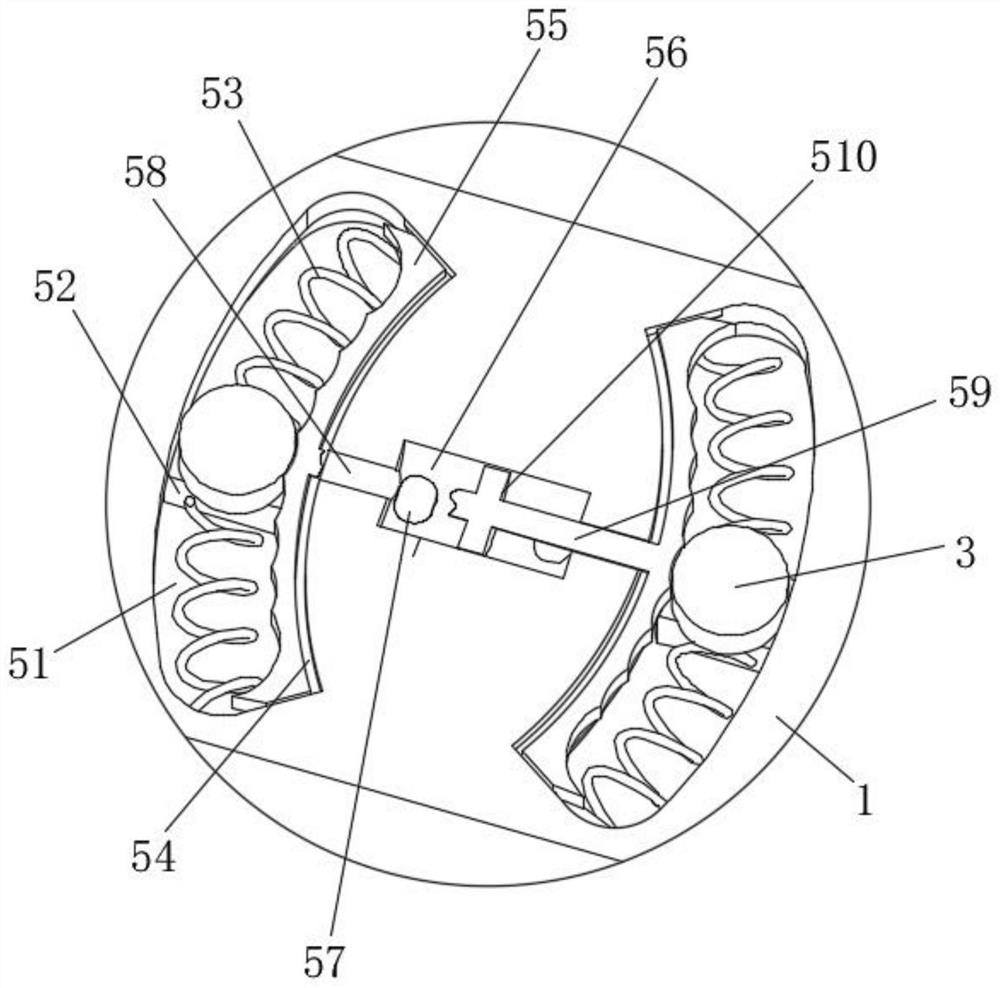

[0034] An avoidance mechanism 5 that reduces the impact of collision is installed between the robot arm 1 and the power rod 3 .

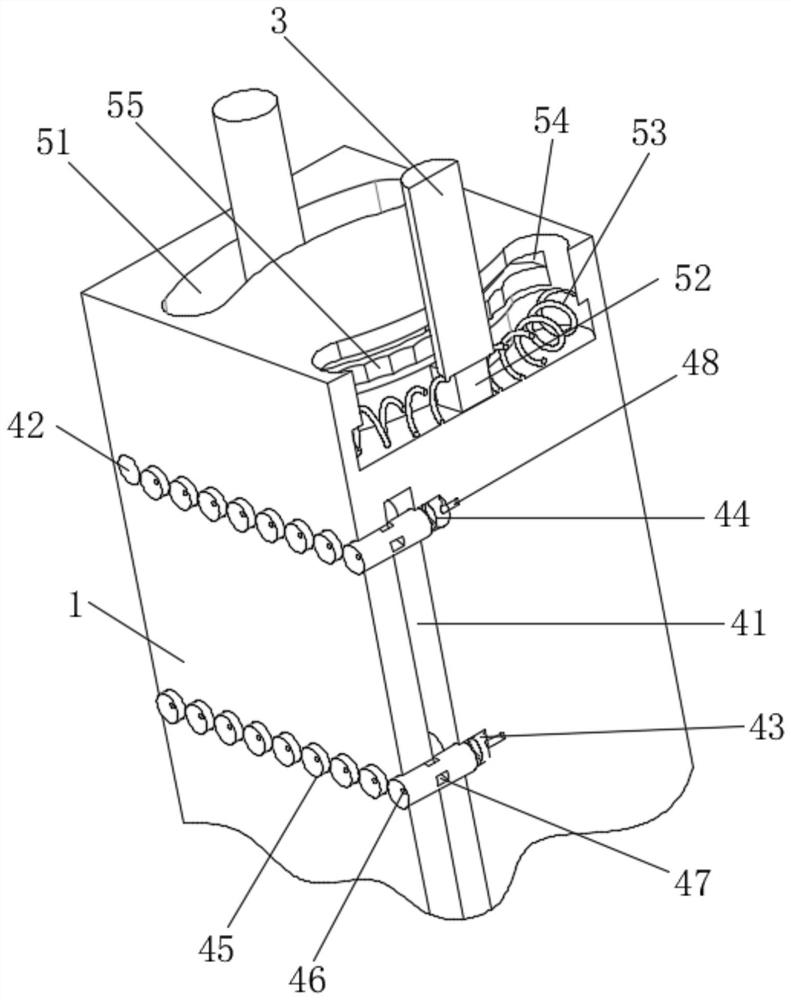

[0035] The induction mechanism 4 includes an air cavity 41 opened on the inner side of the mechanical arm 1;

[0036] The induction mechanis...

Embodiment 2

[0044] see Figure 1-2 , a teaching robot mobile device with anti-collision function, including a mechanical arm 1, the bottom of the mechanical arm 1 is fixedly connected to the clamping piece installation port 2, the top of the mechanical arm 1 is installed with a power rod 3, there are two power rods 3, one The root is located at the center of the top of the robotic arm 1, and the other is located on the side of the top of the robotic arm 1. The power rod 3 is divided into two upper and lower sections, and the two sections are connected by bearings;

[0045] A sensing mechanism 4 for predicting collision is arranged on the outer surface of the robotic arm 1 that is perpendicular to its own running track;

[0046] An avoidance mechanism 5 that reduces the impact of collision is installed between the robot arm 1 and the power rod 3 .

[0047] The induction mechanism 4 includes an air cavity 41 opened on the inner side of the mechanical arm 1;

[0048] The induction mechanis...

Embodiment 3

[0058] see Figure 1-3 , a teaching robot mobile device with anti-collision function, including a mechanical arm 1, the bottom of the mechanical arm 1 is fixedly connected to the clamping piece installation port 2, the top of the mechanical arm 1 is installed with a power rod 3, there are two power rods 3, one The root is located at the center of the top of the robotic arm 1, and the other is located on the side of the top of the robotic arm 1. The power rod 3 is divided into two upper and lower sections, and the two sections are connected by bearings;

[0059] A sensing mechanism 4 for predicting collision is arranged on the outer surface of the robotic arm 1 that is perpendicular to its own running track;

[0060] An avoidance mechanism 5 that reduces the impact of collision is installed between the robot arm 1 and the power rod 3 .

[0061] The induction mechanism 4 includes an air cavity 41 opened on the inner side of the mechanical arm 1;

[0062] The induction mechanis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com