Film supply device

A technology for film supply and mounting board, which is applied in packaging, transportation and packaging, and thin material processing, etc. It can solve the problems of poor user experience, inconvenience, and long time for adding film for operators, and achieve the effect of improving user experience and comfortable operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

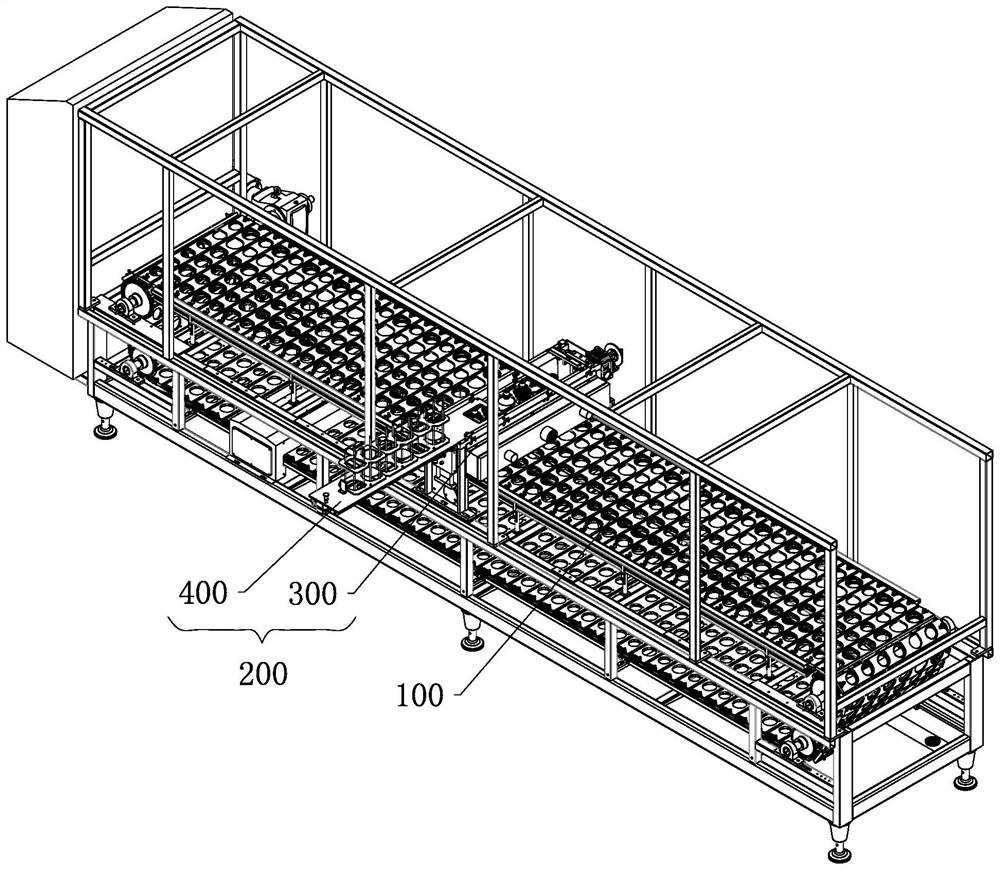

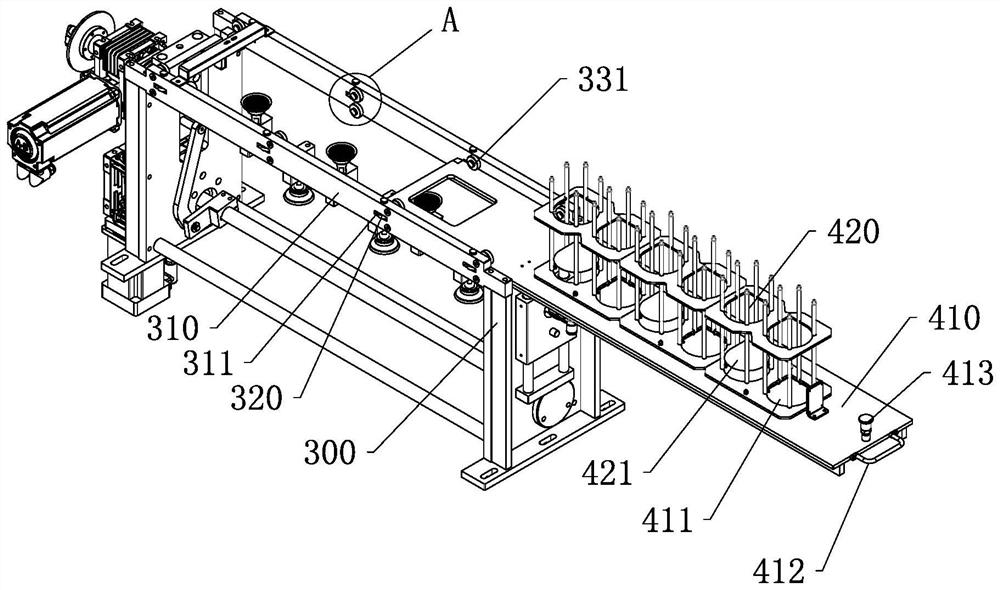

[0037] A film supply device, such as Figure 1 to Figure 3 As shown, it includes a transmission mechanism 100 and a film supply mechanism 200. The transmission mechanism 100 is used to transport unsealed packaging cups, and the film supply mechanism 200 is provided above the transmission mechanism 100 for supplying the packaging cups on the transmission mechanism 100. film, that is, place the sealing film 421 at the mouth of the packaging cup.

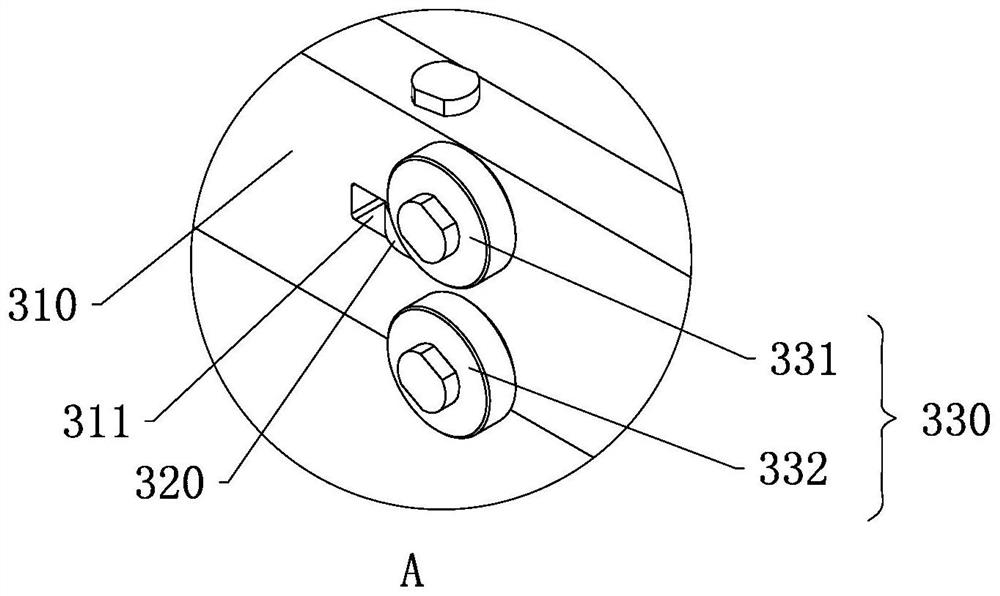

[0038] like figure 2As shown, the film supply mechanism 200 includes a mounting bracket 300 and a mounting plate 400, the mounting plate 400 is horizontally arranged on the mounting bracket 300 for placing the sealing film 421, the mounting bracket 300 is fixed above the transmission mechanism 100, and the mounting plate 400 is slidably connected On the mounting bracket 300 , the mounting plate 400 can be laterally slid relative to the mounting bracket 300 . When the film supplying device is working, the mounting plate 400 is in the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com