Concrete column and steel beam connecting structure

A technology for concrete columns and connecting structures, which is applied in truss structures, columns, joists, etc., can solve the problems of poor connection between steel beams and concrete, low connection structure strength, complicated construction process, etc., and achieves high overall connection structure strength. , Reduce the construction process and improve the effect of shear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

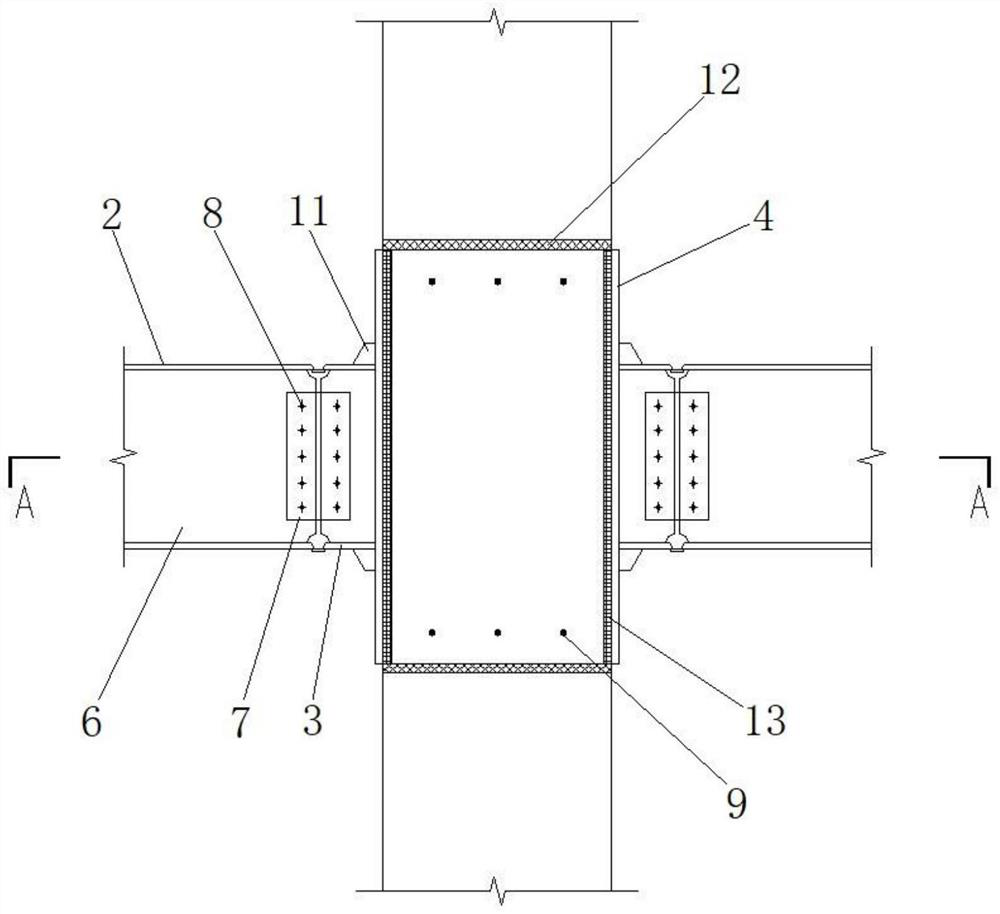

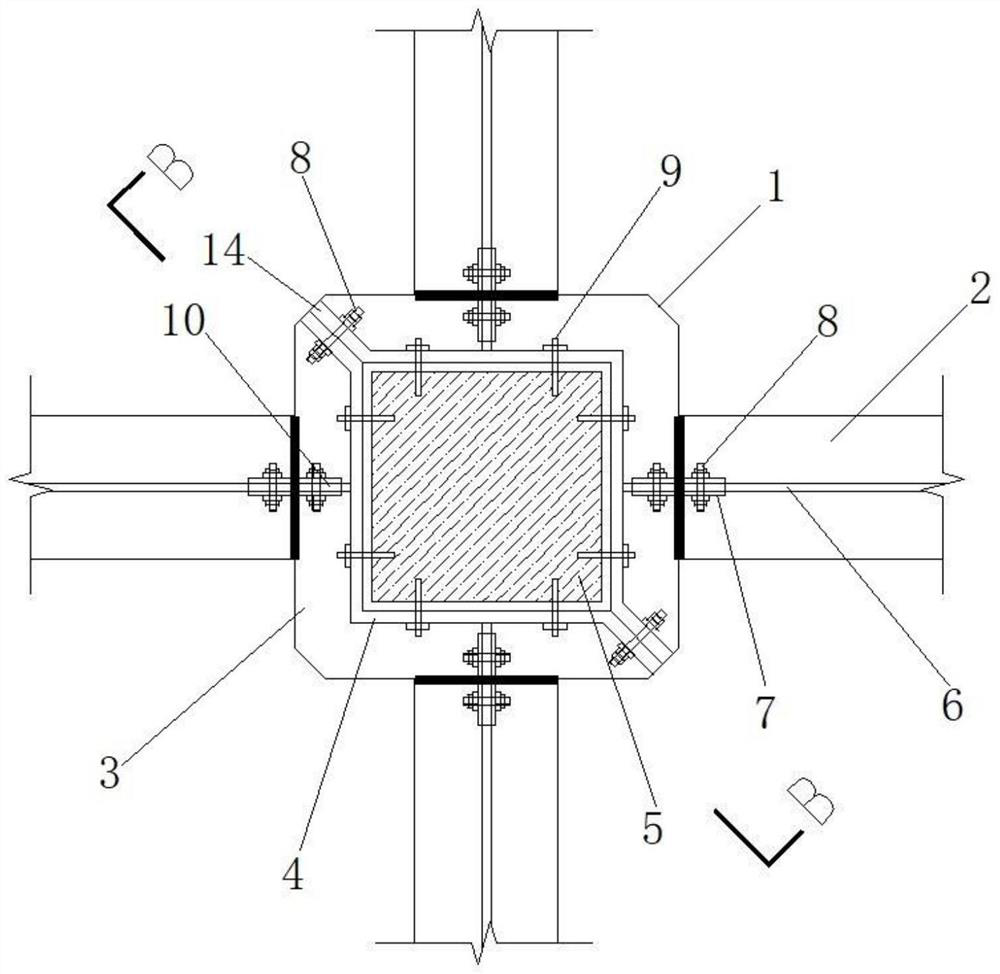

[0034] see Figure 1 to Figure 3 , the present invention provides a concrete column and steel beam connection structure, including a concrete column 5, a connection mechanism 1 and a steel beam 2, the concrete column 5 is square, the connection mechanism 1 is set outside the concrete column 5, the steel beam 2 and the connection mechanism 1. Fixed connection, the connection mechanism 1 includes two connecting end plates 4 symmetrically wrapped on the outside of the concrete column 5, and several anchor bolts 9 are evenly spaced between the upper and lower ends of the connecting end plate 4 and the concrete column 5, and the connecting end plates 4 It is L-shaped, and an assembled rib 14 extends outward from the joint of the two connecting end plates 4. The assembled rib 14 at the joint of the two connecting end plates 4 is fixedly connected by connecting bolts 8, and the connecting end plate 4 and the concrete column 5 are connected. There is a gap between the upper and lower ...

Embodiment 2

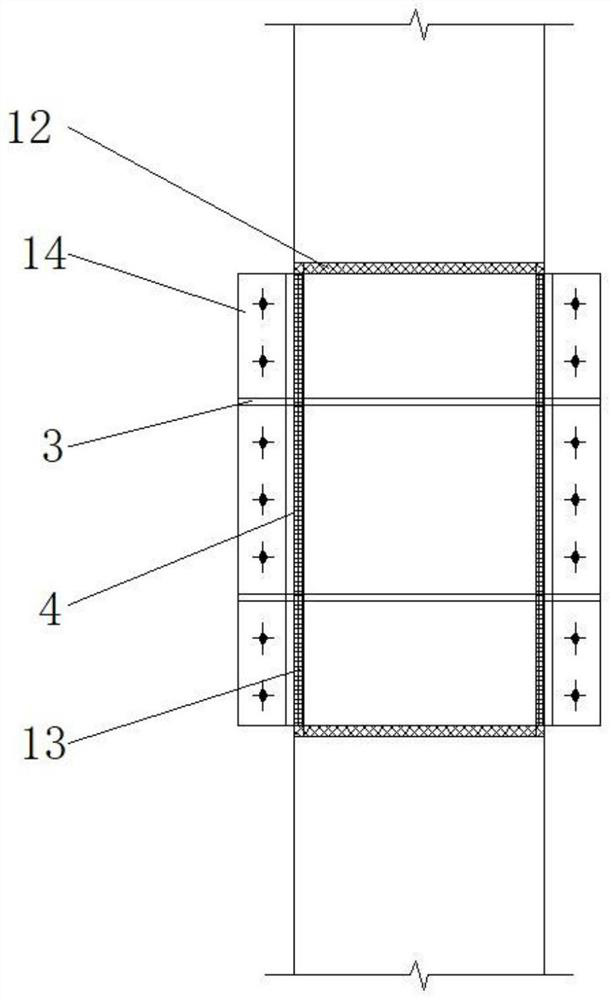

[0036] see Figure 4 to Figure 6, the present invention provides a concrete column and steel beam connection structure, including a concrete column 5, a connection mechanism 1 and a steel beam 2, the concrete column 5 is square, the connection mechanism 1 is set on the outer surface of the concrete column 5, and the steel beam 2 is connected with The mechanism 1 is fixedly connected, and the connection mechanism 1 includes two connecting end plates 4 symmetrically covered on the outer surface of the concrete column 5. Several anchor bolts 9 are evenly spaced between the upper and lower ends of the connecting end plate 4 and the concrete column 5. The plate 4 is semi-circular, and there are assembled rib plates 14 extending outward from the joints of the two connecting end plates 4. The assembled rib plates 14 at the joints of the two connecting end plates 4 are fixedly connected by connecting bolts 8, and the connecting end plates 4 are connected with the concrete. There is a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com