Prestressed PBL stiffening-type steel box concrete composite beam and construction method thereof

A steel box concrete and stiffening technology, which is applied in bridges, bridge construction, erection/assembly of bridges, etc., can solve problems such as poor coordination between beams and floors, increased self-weight, and easy local buckling, so as to improve bearing capacity and resistance. Effects of bending stiffness, increasing degree of restraint, and reducing interface slip

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

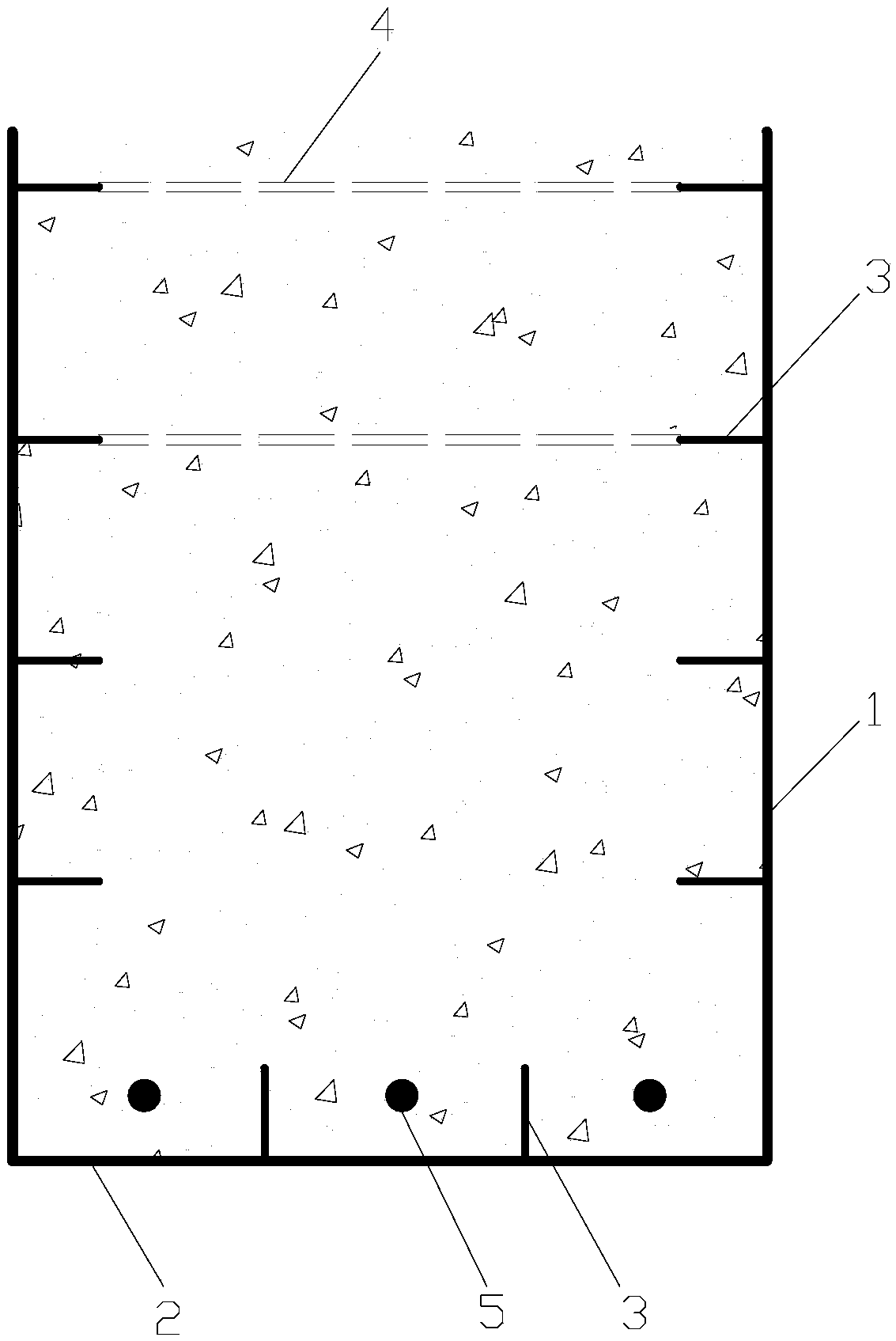

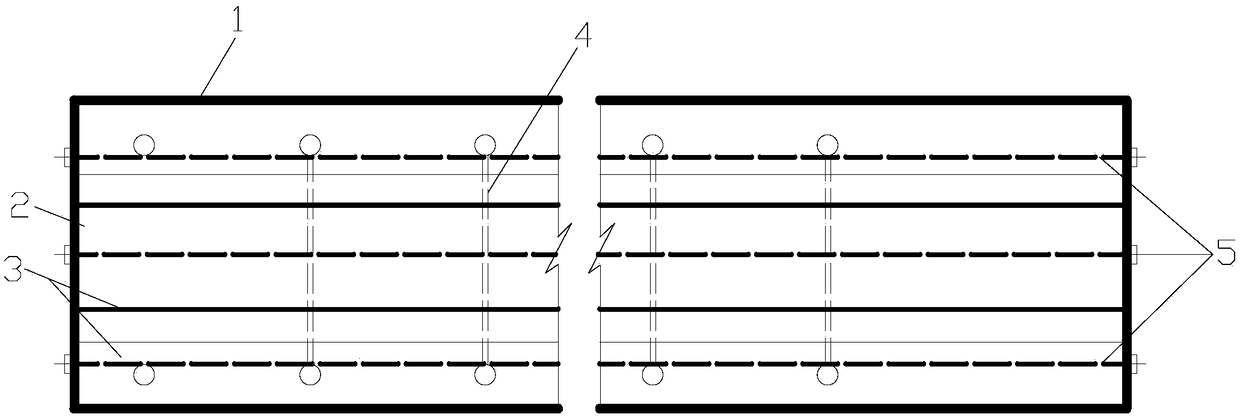

[0020] like figure 1 , figure 2 As shown, a prestressed PBL reinforced steel box concrete composite beam of the present invention includes a web 1 and a bottom plate 2, the web 1 and the bottom plate 2 form a box chamber for filling concrete, and the top of the box chamber is an opening shape, the inner surface of the web 1 and the upper surface of the bottom plate 2 are provided with PBL stiffeners 3, and the PBL stiffeners 3 corresponding to the compression area of the box chamber are connected by transverse tie rods 4, and the tension area of the box chamber Axial prestressing tendons 5 are provided.

[0021] The transverse direction represents the width direction of the beam, and the axial direction represents the span direction of the beam. The compression area and tension area refer to the part below the neutral axis when the flexural membe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com