Screening equipment capable of pre-weighing and used for screening concrete raw materials

A technology for screening equipment and concrete, which is applied in the fields of filtration, solid separation, chemical instruments and methods, etc. It can solve the problems of a large amount of dust, pulley damage, affecting use, etc., and achieve the effect of facilitating subsequent use and improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

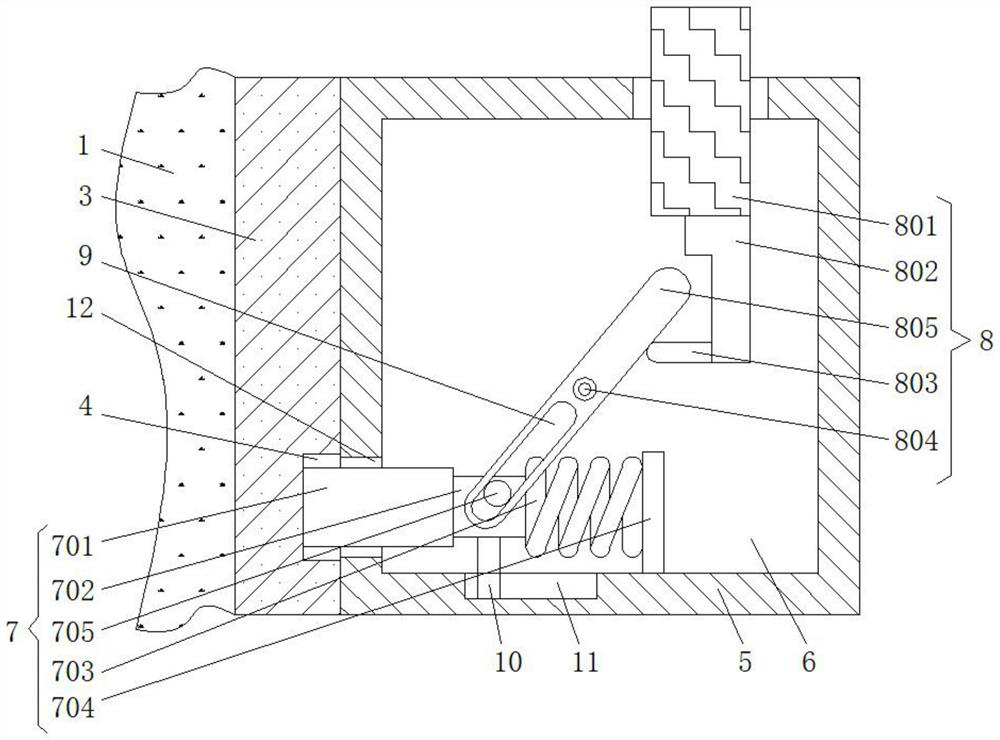

[0021] In order to further understand the content, features and effects of the present invention, the following examples are given, and detailed descriptions are given below with reference to the accompanying drawings.

[0022] The structure of the present invention will be described in detail below in conjunction with the accompanying drawings.

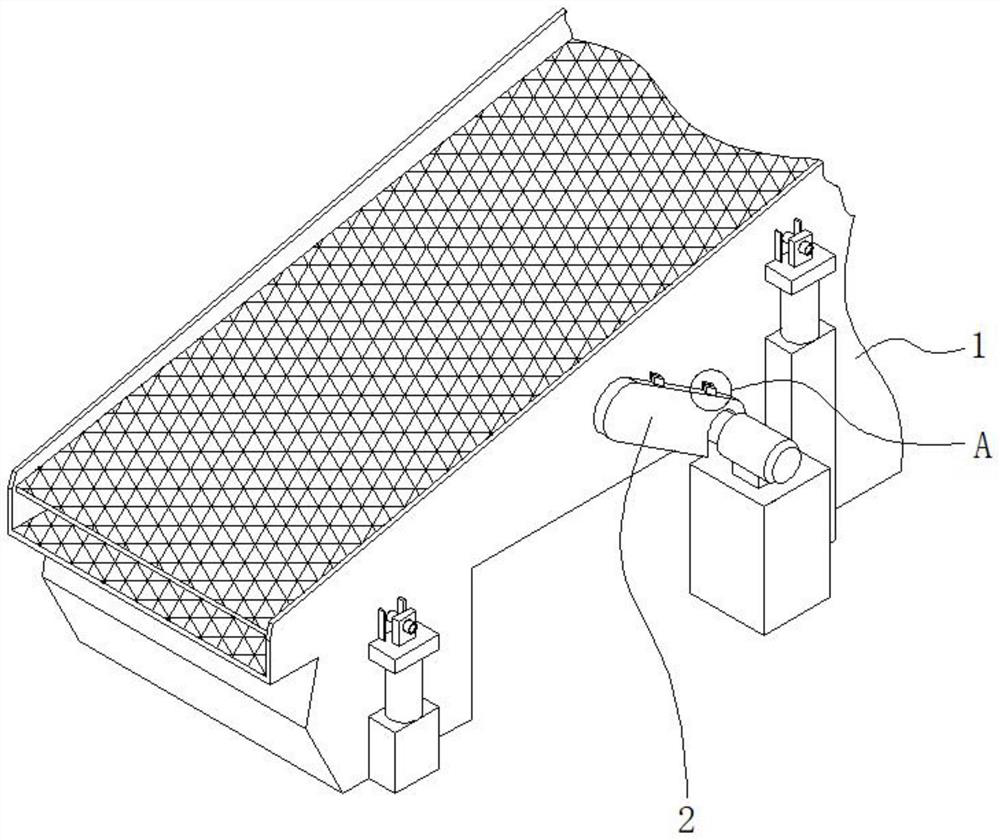

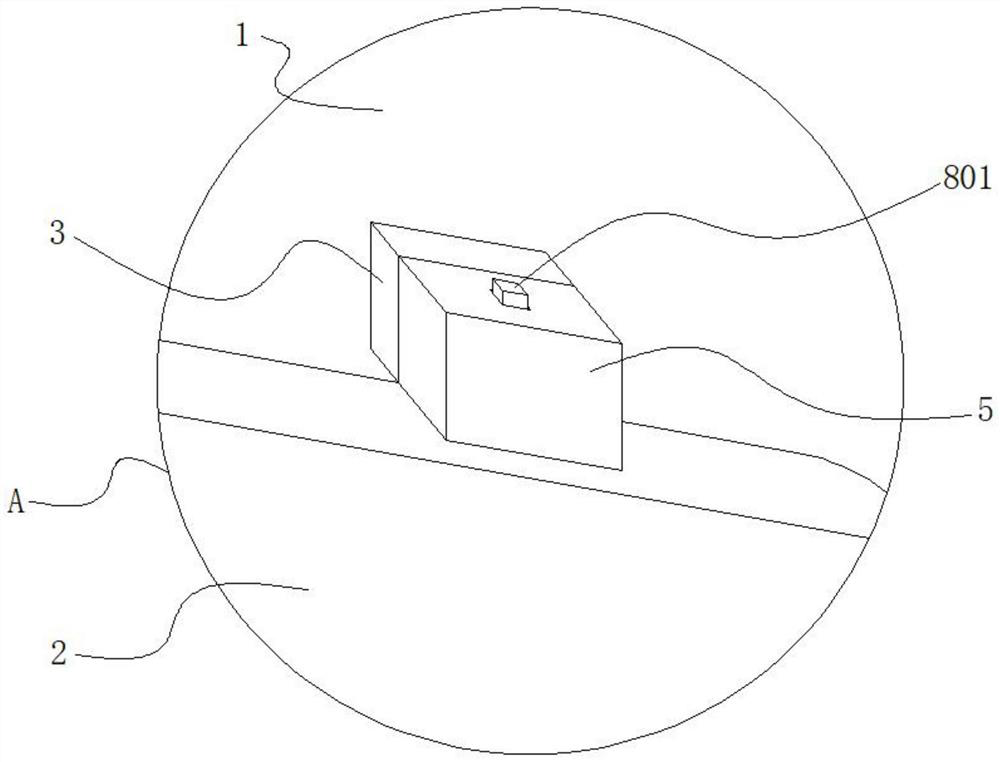

[0023] Such as Figure 1 to Figure 3 As shown, a kind of pre-weighable screening equipment for screening raw materials of concrete provided by the embodiment of the present invention includes a screening machine 1 and a protective cover 2, the protective cover 2 is located on the right side of the screening machine 1, and the right side of the screening machine 1 is fixed Two limiting plates 3 are connected, and the right side of the limiting plate 3 is provided with a snap-in groove 4, and the top of the protective cover 2 is fixedly connected with two fixing blocks 5 used in conjunction with the limiting plates 3, and the inside of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com