Accurate positioning ultrasonic welding device for plastic products

An ultrasonic welding and precise positioning technology, applied in the field of welding processing, can solve the problems of pipeline positioning, complicated welding process, manual placement and fixing operation, etc., and achieve the effect of precise control and convenient ultrasonic welding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

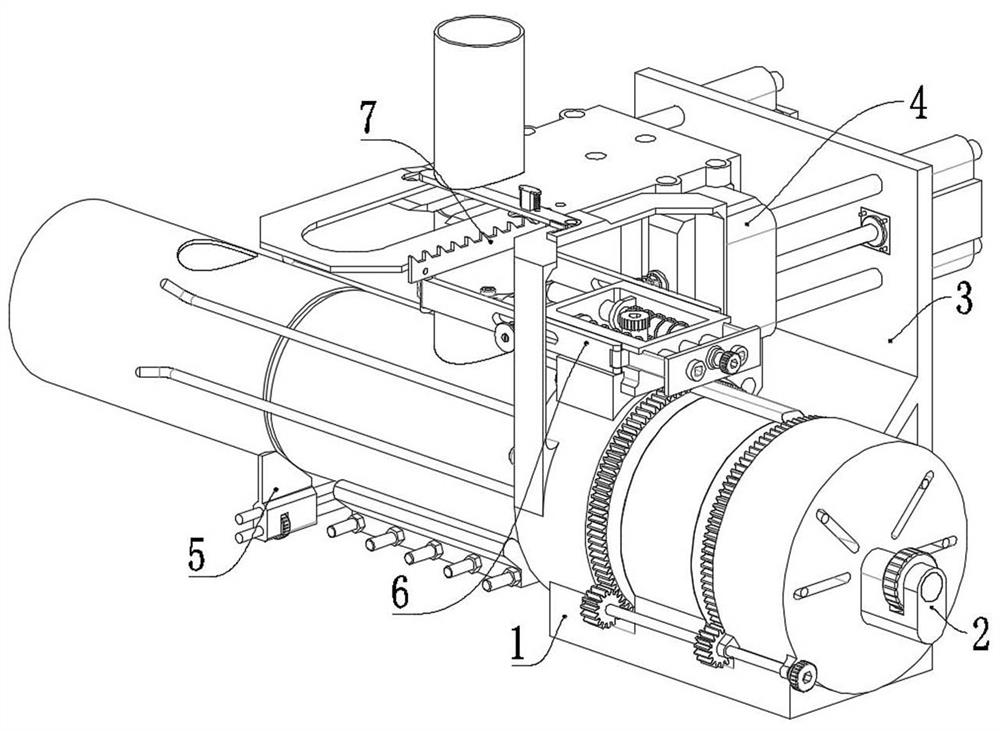

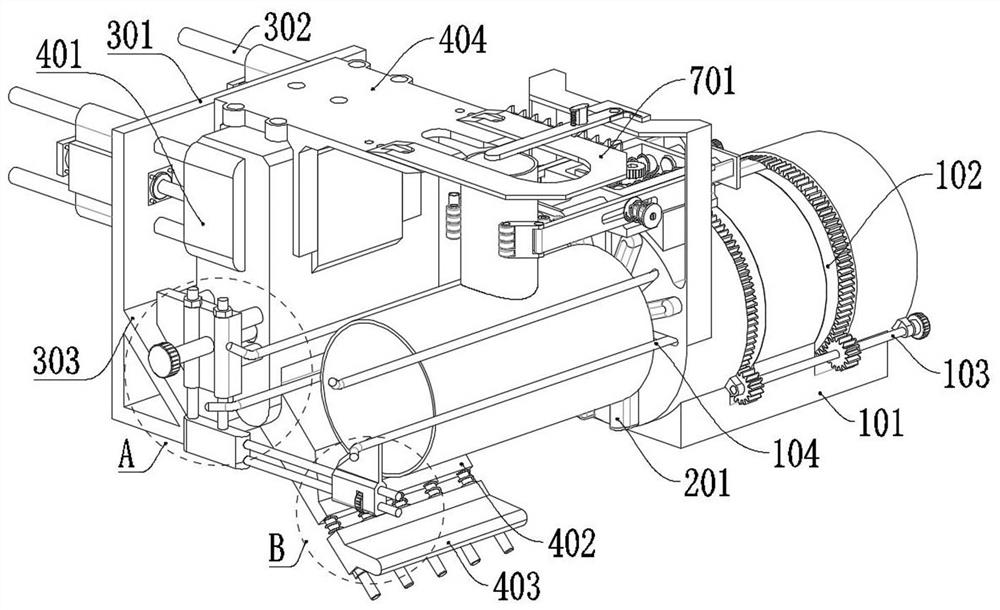

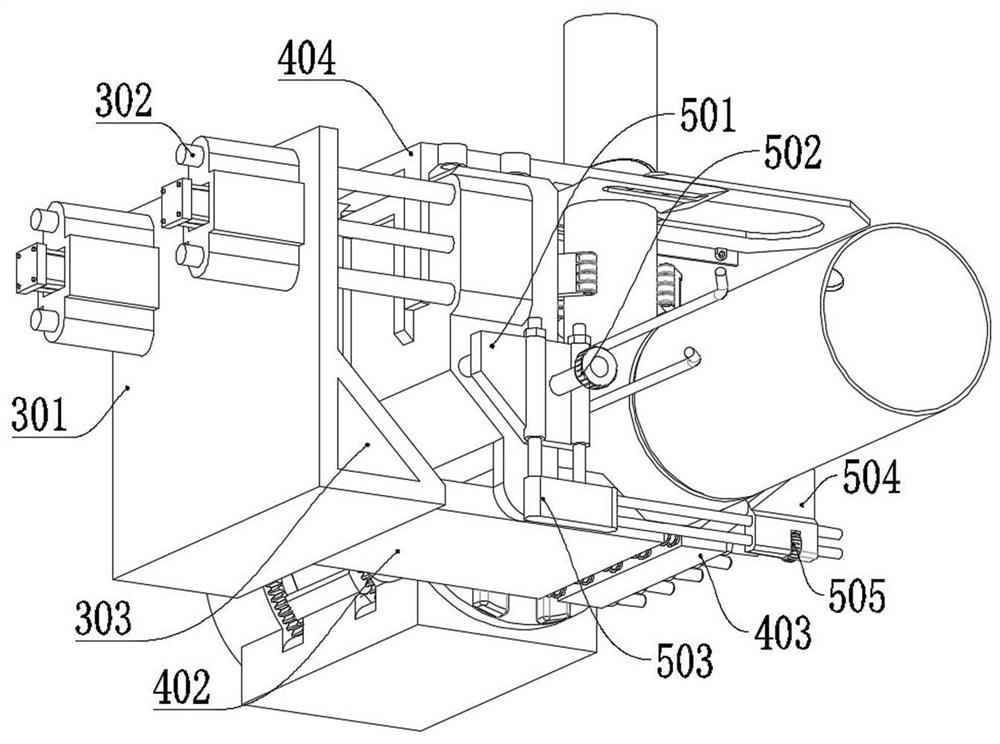

[0063] Example: Please refer to Figure 1 to Figure 11 :

[0064] The present invention proposes a precise positioning ultrasonic welding device for plastic products, including: a guiding structure 1;

[0065] The position of the inner axis of the guide structure 1 is provided with a limit assembly 2; the limit assembly 2 includes: a limit rod 201, the left end of the limit rod 201 is set as a circular frame structure, and the right end of the limit rod 201 is fixed with a connecting rod. The circular frames are perpendicular to each other. Through the limit rod 201 composed of the connecting rod and the circular frame, the left end of the limit rod 201 can be directly supported on the pipeline, thereby realizing the limit and fixing of the position of the pipeline. The limit rod 201 Installed on the central axis position of the fixed seat 101 through the connecting shaft; the auxiliary block 202, the auxiliary block 202 is fixed at the middle position of the right end of the...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap