A source dismantling auxiliary device for medical radioactive source

An auxiliary device and radioactive source technology, applied in radiation therapy, X-ray/γ-ray/particle irradiation therapy, treatment, etc., can solve the problem that the cobalt source loading and unloading operation cannot be carried out smoothly, the locking parts are oxidized and corroded, and the cobalt source cannot be separated, etc. problem, to solve the problem of insufficient extraction force, improve the efficiency of disassembly and assembly, and achieve the effect of rapid replacement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

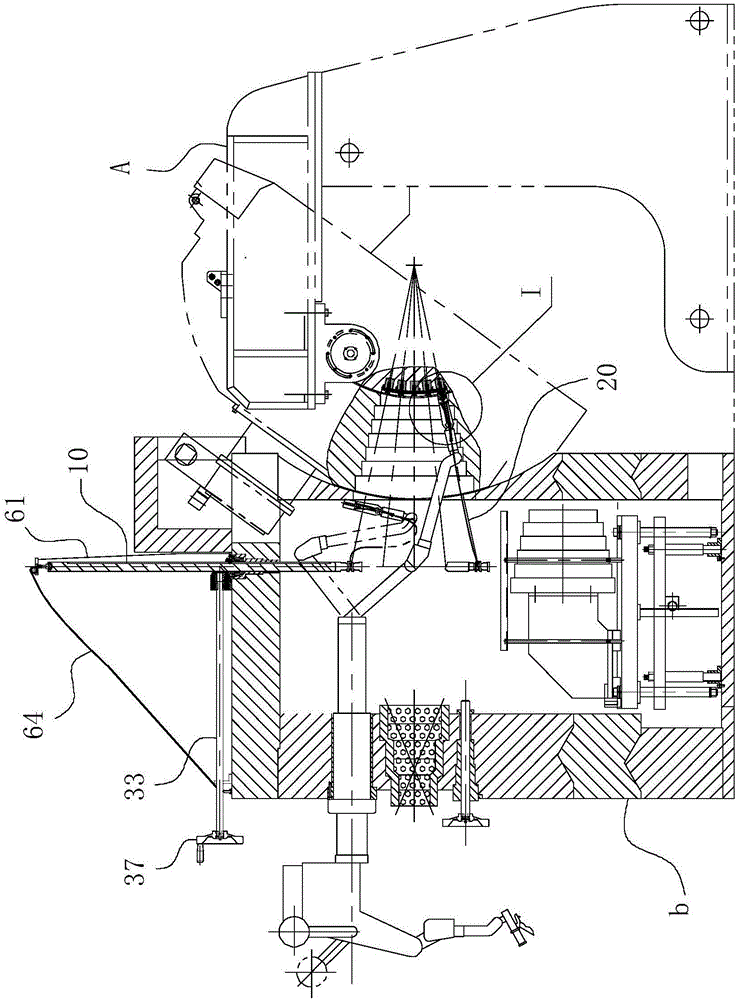

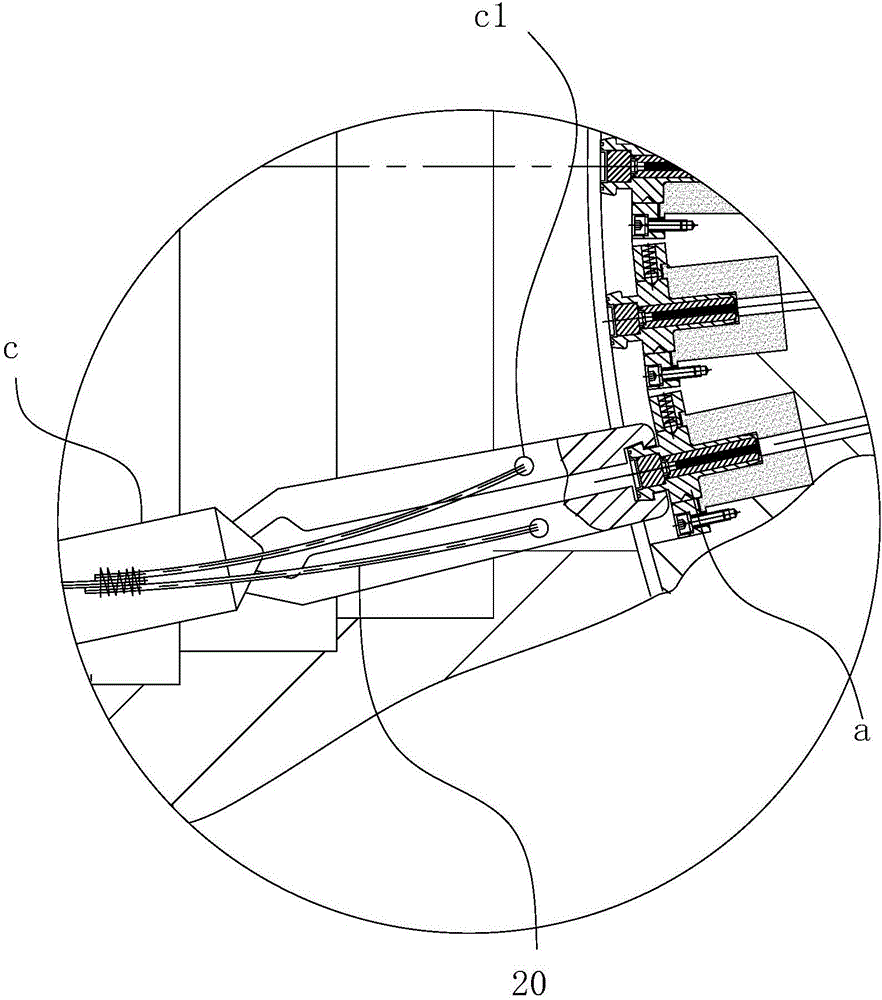

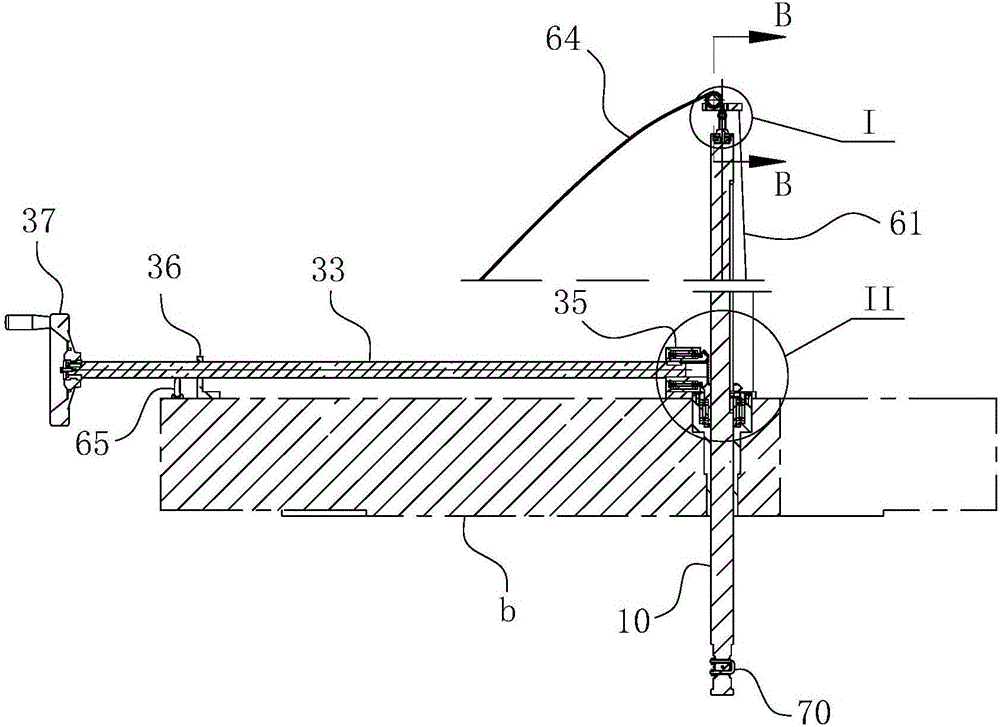

[0040] For ease of understanding, the specific implementation structure and workflow of the present invention are described below in conjunction with the accompanying drawings:

[0041] The original design intention of the present invention is to provide an extra pulling force to the manipulator at the source loading machine when the traditional source loading machine unloads the source, so that the cobalt source can be reliably separated from the installation hole. Under the above thinking, the present invention adopts such as Figure 1-7 construction shown. It should be noted, Figure 1-7 The structure shown is an example of the loading and unloading of the source-loading equipment in the body, which is embodied in drilling a rotary hole at the top shield plate of the heat chamber b, and then loading the device. For the head-mounted source equipment, the turning holes should be drilled at the shielding plates on both sides of the heat chamber b. At this time, the shaft of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com