A Novel Cooling Device in a Pilot Valve Seat Cutting Device

A technology of cutting device and cooling device, which is applied in the direction of metal processing equipment, maintenance and safety accessories, metal processing machinery parts, etc., can solve the problems of reducing the temperature of the workpiece and the tool, the soft texture of the bellows, and the damage of the tool, so as to prolong the service life , Simple structure, smooth and convenient cooling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

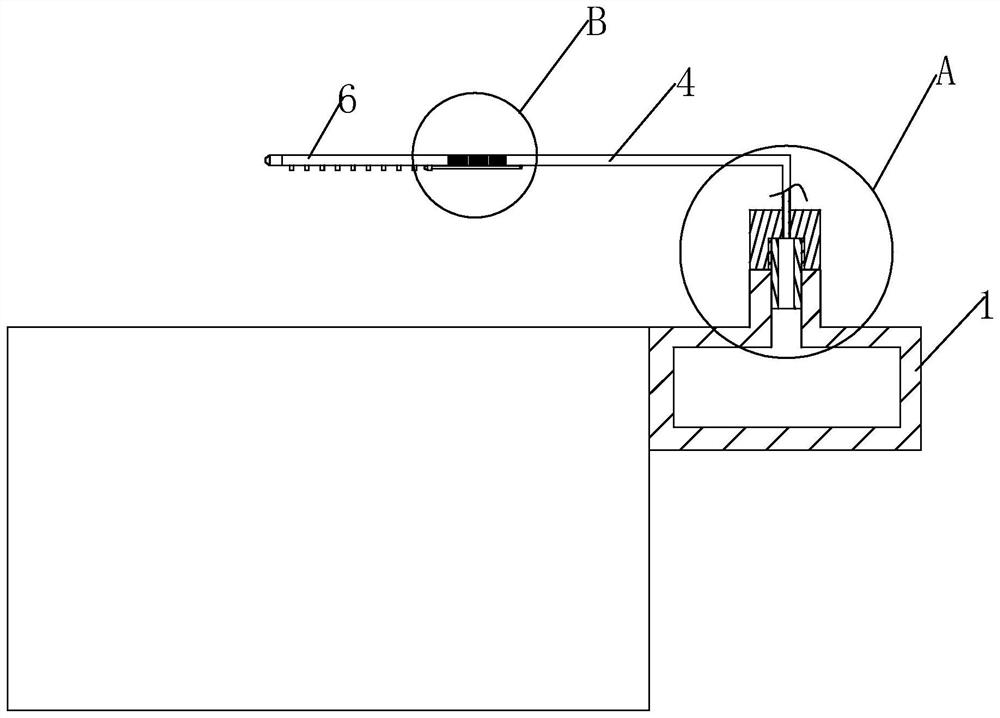

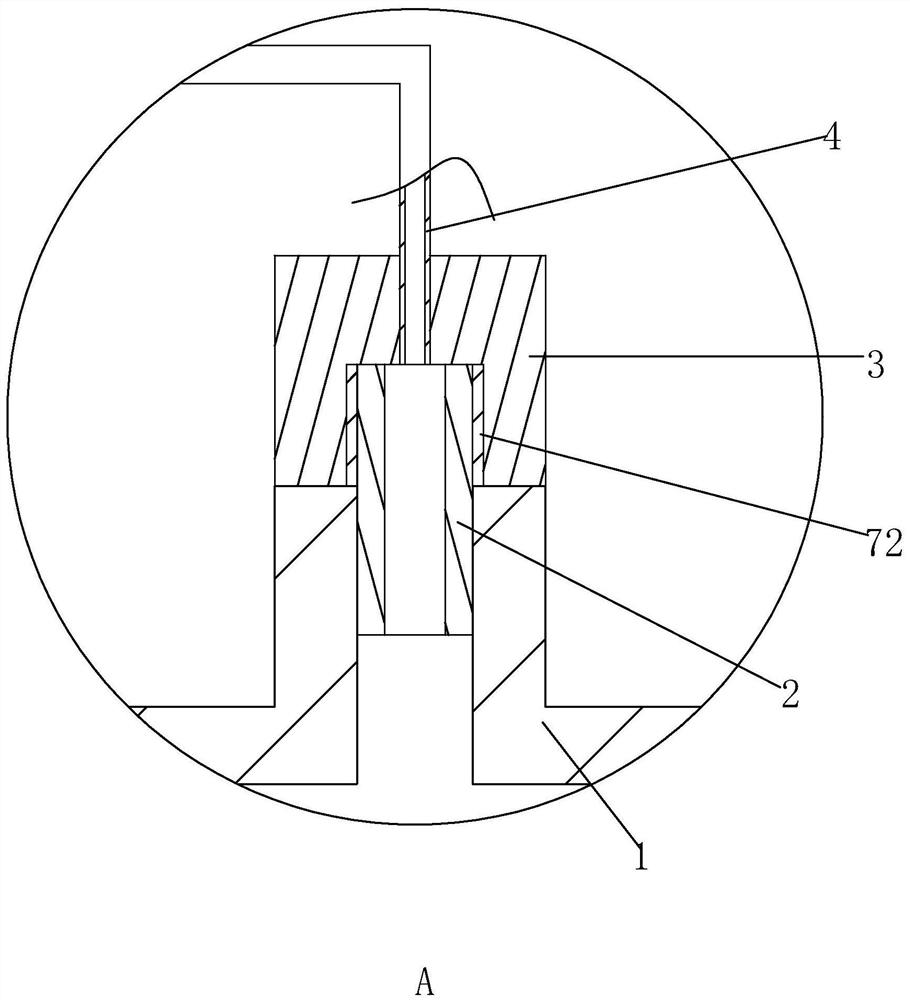

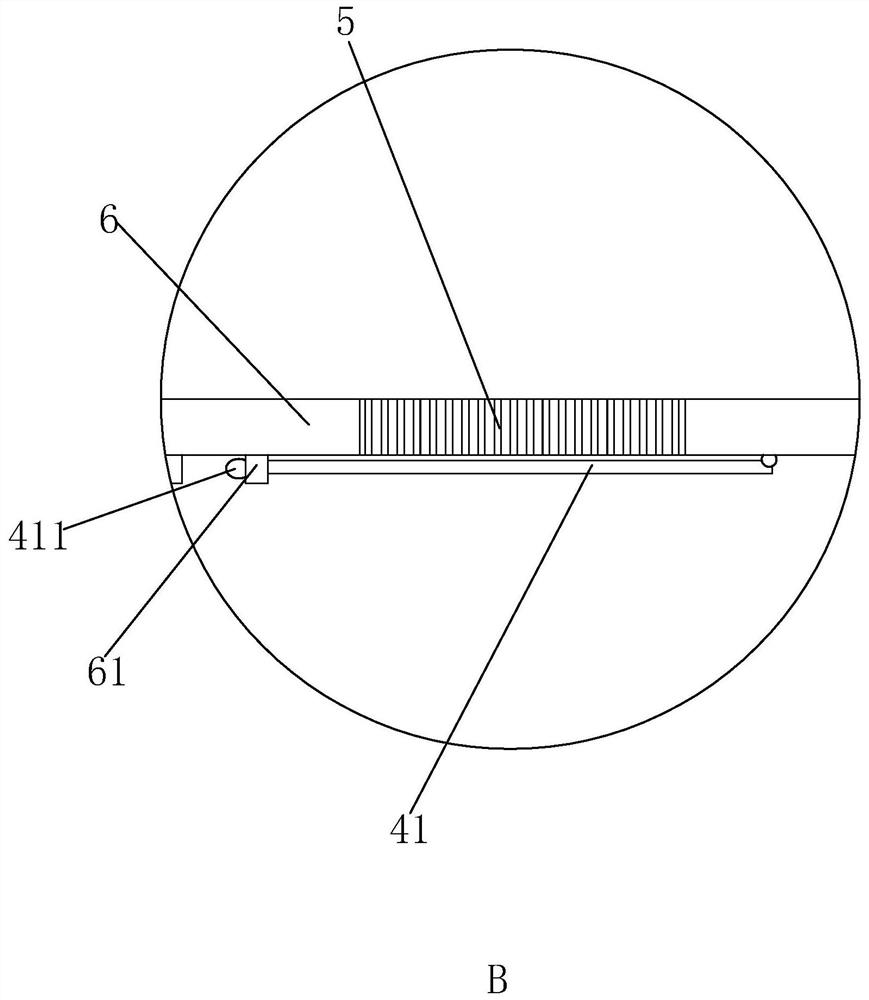

[0020] Embodiment 1: A novel cooling device in a pilot valve seat cutting device, such as Figure 1-3 As shown, it includes a liquid storage tank 1 arranged on a numerically controlled lathe, a bearing 2 is fixedly provided at the liquid outlet of the liquid storage tank 1, and a rotating support 3 is fixedly provided on the outer peripheral wall of the bearing 2, At the same time, a sealing ring 72 is provided between the bearing 2 and the rotating support 3 to ensure the tightness; on the rotating support 3, a connecting pipe 4 communicating with the inside of the liquid storage tank 1 is fixed, and the connecting pipe 4 The end away from the rotating support 3 is fixed with a bellows 5, and the end of the bellows 5 away from the connecting pipe 4 is connected and fixed with a liquid outlet pipe 6. The connecting pipe 4 and the liquid outlet pipe 6 are both made of stainless steel. At the same time, a connecting bracket 41 is provided on the outer wall of the connecting pipe...

Embodiment 2

[0023] Embodiment 2: A novel cooling device in a pilot valve seat cutting device, the difference from Embodiment 1 is that, as Figure 4 and 5 As shown, the bellows 5 is respectively connected to the connection pipe 4 and the liquid outlet pipe 6 through the detachable connection mechanism 7 , and the detachable connection mechanism 7 includes a clamp 71 and a sealing ring 72 .

[0024] That is to say, the sealing ring 72 is respectively sleeved on the ends of the connecting pipe 4 and the liquid outlet pipe 6, and then the bellows 5 is sleeved on the sealing ring 72, and finally the clamp 71 is used to realize the fixing function, the structure is simple, and the assembly and disassembly are convenient. It is convenient to replace the bellows 5 at any time to prolong the service life of the cooling device; at the same time, the bellows 5 and the liquid outlet pipe 6 can be completely removed from the connecting pipe 4 so as to replace and connect other required pipes accordin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com