UV drying device of screen printing machine

A technology of screen printing machine and drying device, which is applied to screen printing machines, printing machines, rotary printing machines, etc., can solve the problems of inability to adjust UV lamps, poor ventilation effects, and failure to achieve drying effects, etc., to achieve The effect of maintaining temperature and drying efficiently

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

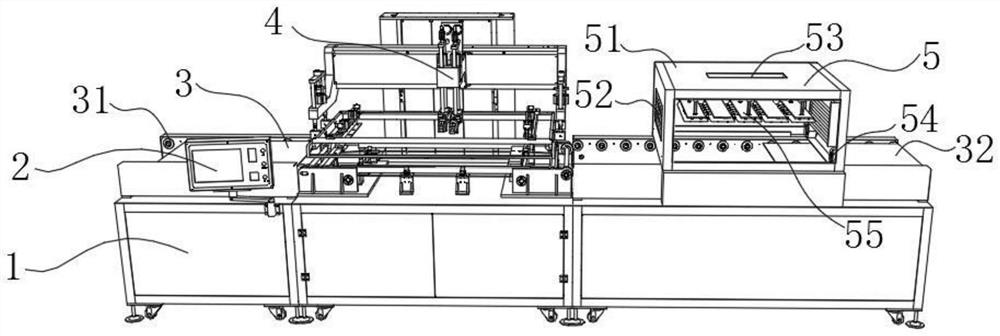

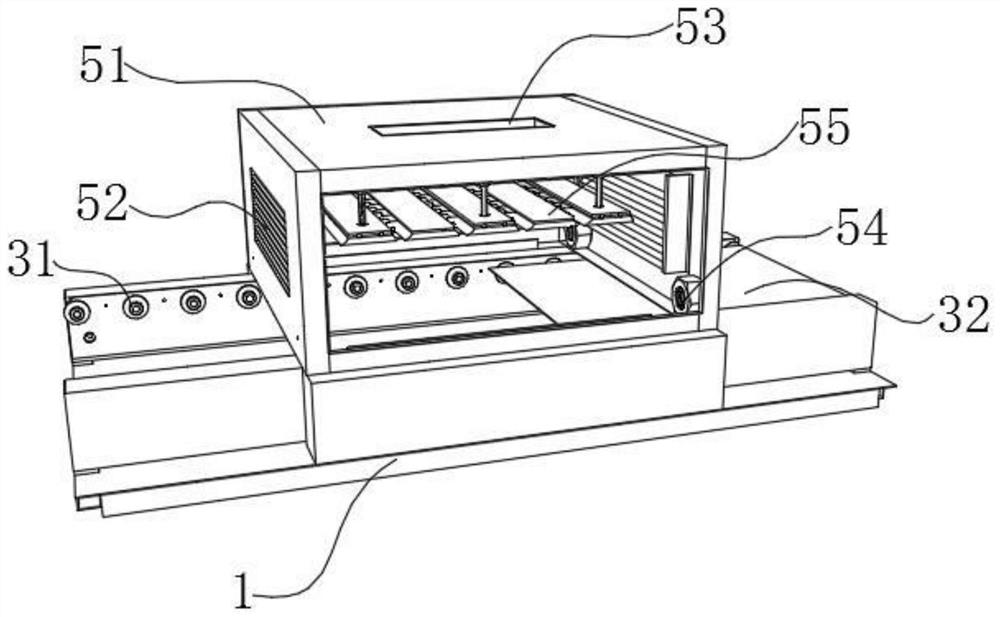

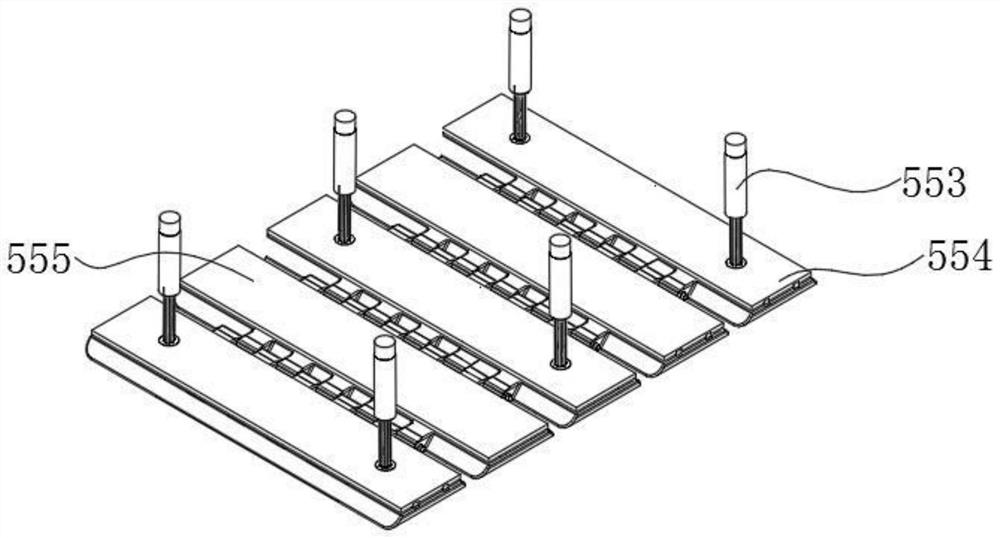

[0048] see Figure 1~6 , in an embodiment of the present invention, a UV drying device for a screen printing machine, comprising:

[0049] Rack 1, carrying working equipment;

[0050] The electrical box 2 is fixed on the frame 1 and is located at one end of the frame 1, controlling the operation and power supply of the working equipment;

[0051] The conveying device 3 is horizontally arranged on the frame 1 and runs through the whole frame 1;

[0052] The printing device 4 is fixedly arranged in the middle of the frame 1, above the conveying device 3, and performs printing work;

[0053] The drying device 5 is fixed on the frame 1, and the end opposite to the electrical box 2 is located at the end of the conveying device 3 to dry the printed matter.

[0054] In this embodiment, the delivery device 3 includes:

[0055] A plurality of conveying rollers 31 are symmetrically distributed, and are rotatably fixed on both sides inside the frame 1, and the conveying rollers 31 on...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com