Anti-sticking down jacket liner convenient to disassemble and assemble and manufacturing method thereof

A down jacket and liner technology, which is applied in the field of down jackets, can solve the problems of not being able to disassemble the liner of down jackets and inconvenient wearing, and achieve the effect of ensuring service life and comfort

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

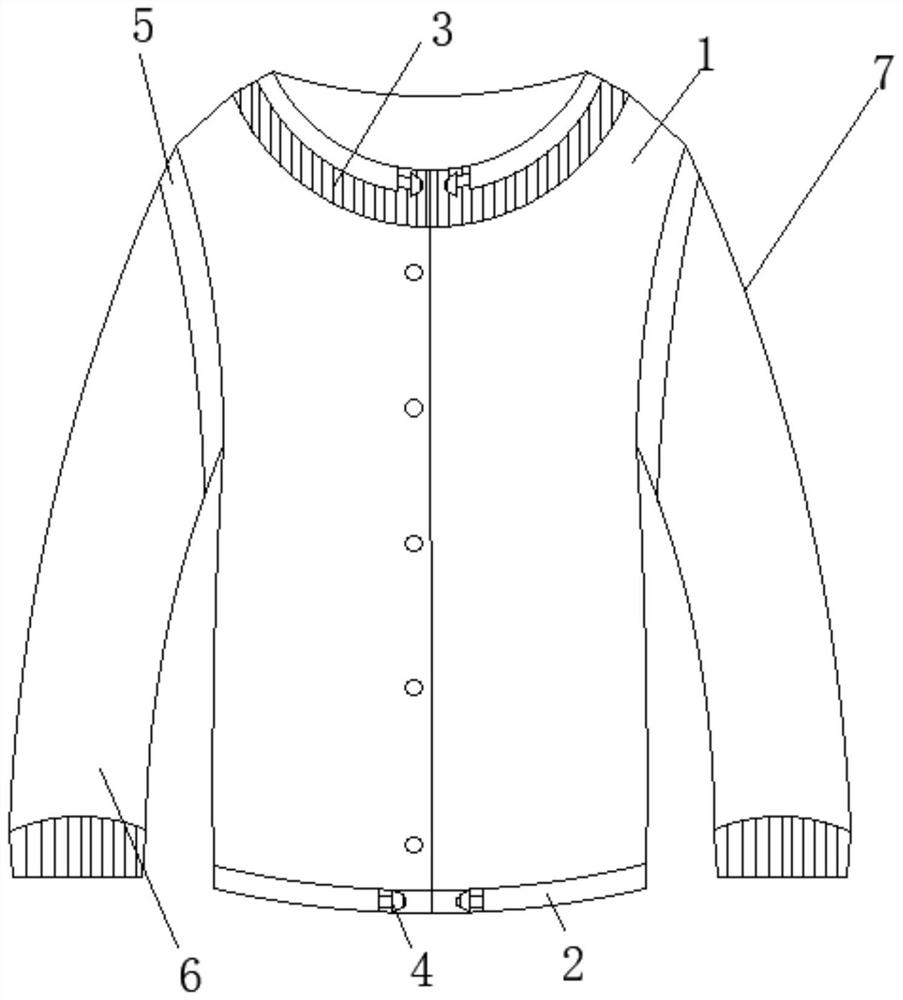

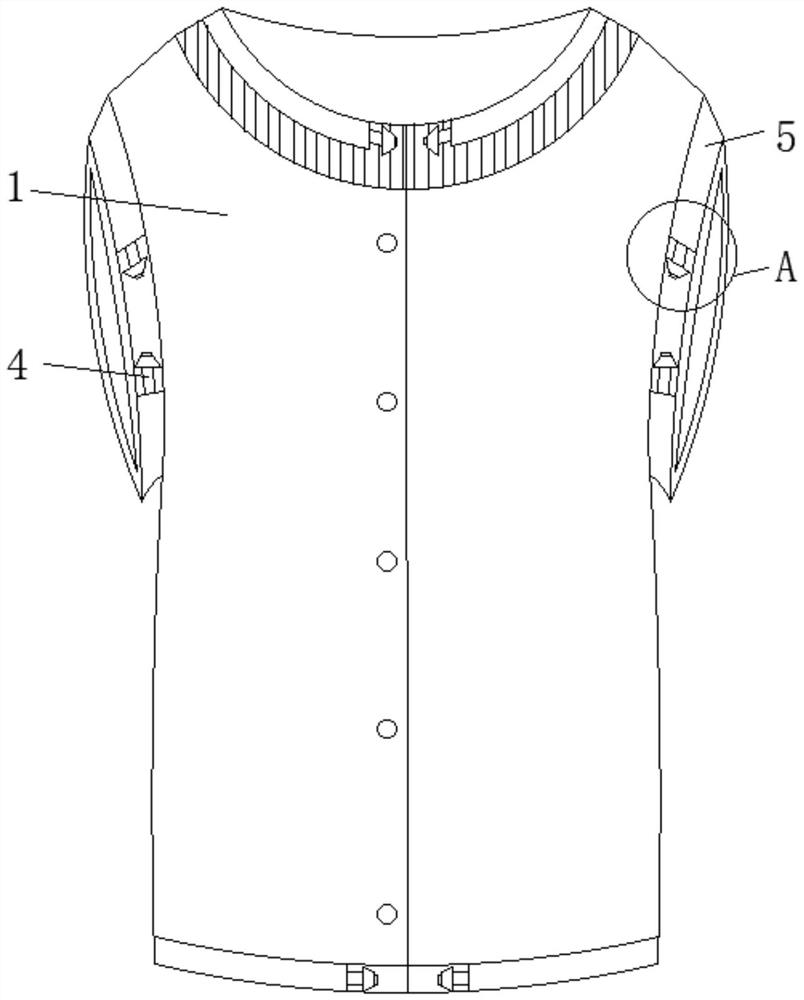

[0034] like Figure 1-3 As shown, an anti-stick down jacket liner that is easy to disassemble and assemble includes an inner liner body 7, and the inner liner body 7 is composed of a body 1, a collar 3 and two sleeves 6, and also includes a body 1 and a collar. 3, the assembly belt 2, the connecting parts 5 located on both sides of the body 1, the locking parts 4 located on the assembly belt 2 and the connecting part 5 and used for disassembly and assembly of the inner bladder of the down jacket and preventing excessive deformation;

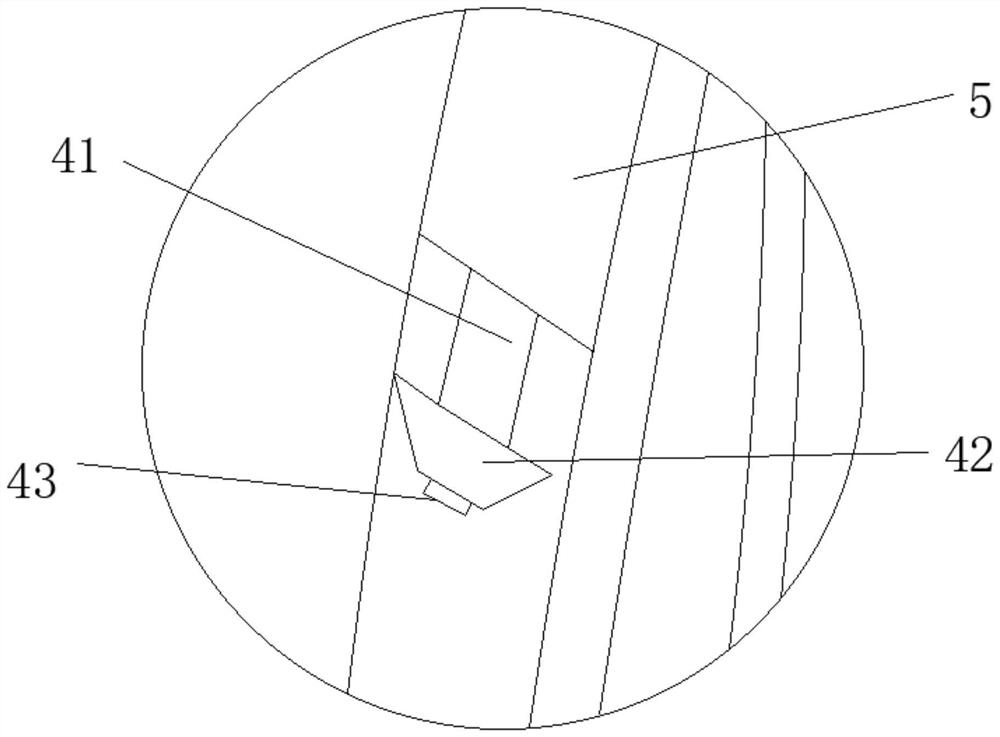

[0035] The locking member 4 includes a clamping column 41 connected with the connecting portion 5 and the assembly belt 2 respectively, a rubber block 42 located on the side of the clamping column 41 facing away from the engaging portion 5, and a No. 1 rubber block 42 located on the side facing away from the clamping column 41. For the adsorption block 43, the size of the rubber block 42 toward the No. 1 adsorption block 43 is smaller than the si...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com