High-performance composite rubber strip for self-sealing safety tire and production method of high-performance composite rubber strip

A safety tire and self-sealing technology, applied to tire parts, tires, applications, etc., can solve problems such as flanging, rubber material falling off, and accumulation, and achieve low production costs, prolong service life, and reduce use costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

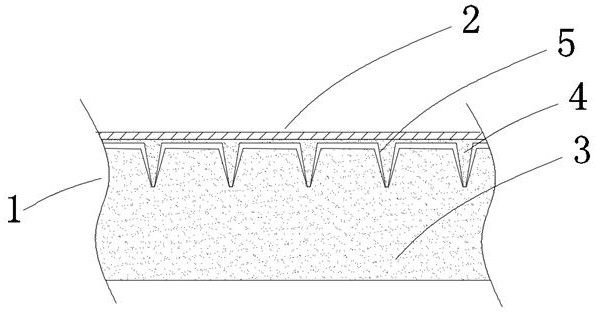

like Figure 1-2 As shown, a high-performance composite rubber strip for self-sealing safety tires includes a self-sealing material layer 1 and an elastic film 2 arranged on the upper side of the self-sealing material layer. The self-sealing material layer includes a self-sealing filling material 3 and a wrapping In the support sheet layer 4 near the elastic film side in the self-sealing filling material, the support sheet layer is composed of a plurality of bowl-shaped support sheets 5, and the concave surface of the support sheet faces the side away from the elastic film; The support sheets are connected, and the connection is a weak point that is easy to disconnect, for example, it can be made into a form similar to an easy tear line; the support sheet layer has a certain support for the entire rubber strip, so that the rubber strip is not easy to fall off. , flanging, displacement and rubber accumulation; the self-sealing rubber strip body is used to lay on the inner side o...

Embodiment 2

Similar to Embodiment 1, the difference lies in that the supporting pieces are connected with adjacent supporting pieces, and there is no gap between adjacent supporting pieces.

[0037] Correspondingly, a method for producing a high-performance composite rubber strip for self-sealing safety tires includes the following steps:

Lay the elastic film on a flat surface, apply glue, place the supporting sheet layer without gap between the supporting sheets on the elastic film, make the supporting sheet layer and the elastic film bond, pour in the self-sealing slurry, self-leveling or mechanical processing. After flattening, cool the release film for use; when placing the support sheet, the concave side of the support sheet is facing up.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com