Oil separator for compression refrigeration system

A technology of compression refrigeration and oil separator, used in refrigerators, refrigeration components, refrigeration and liquefaction, etc., can solve the problems of inaccurate compressor lubrication, false alarm compressor, unstable oil level, etc., to solve the problem of oil level The effect of fluctuating up and down, clever idea and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

Example: an oil separator for a compression refrigeration system

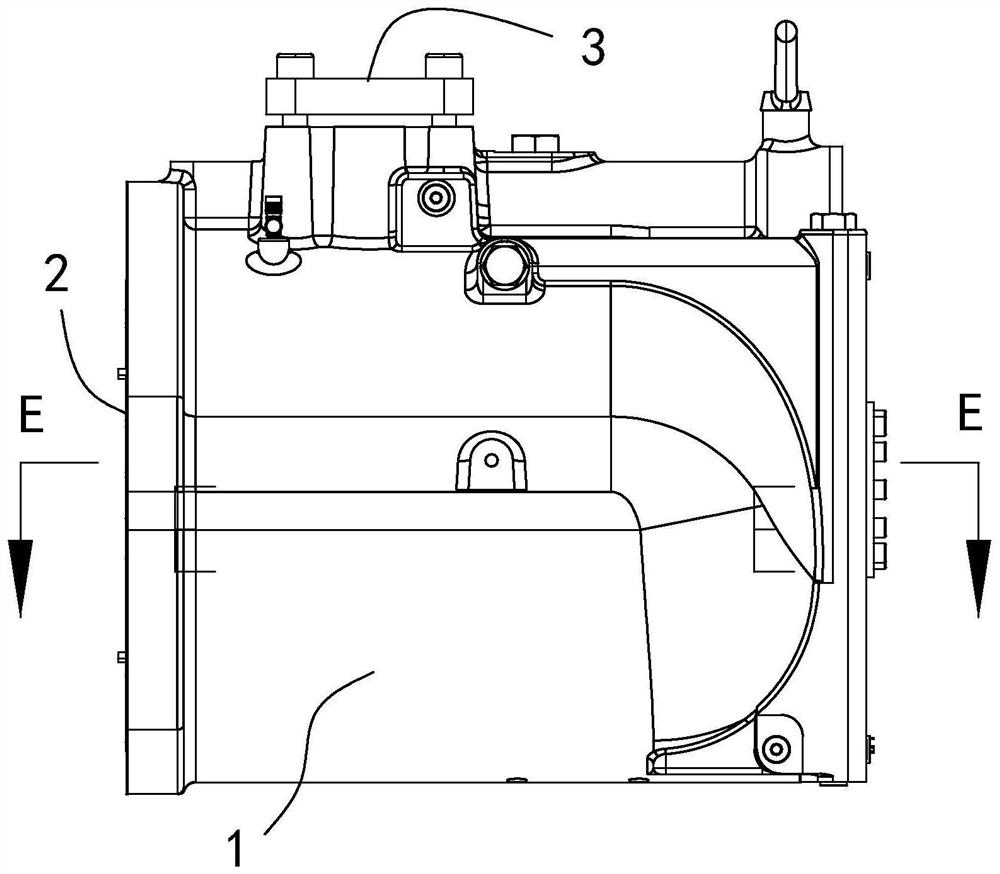

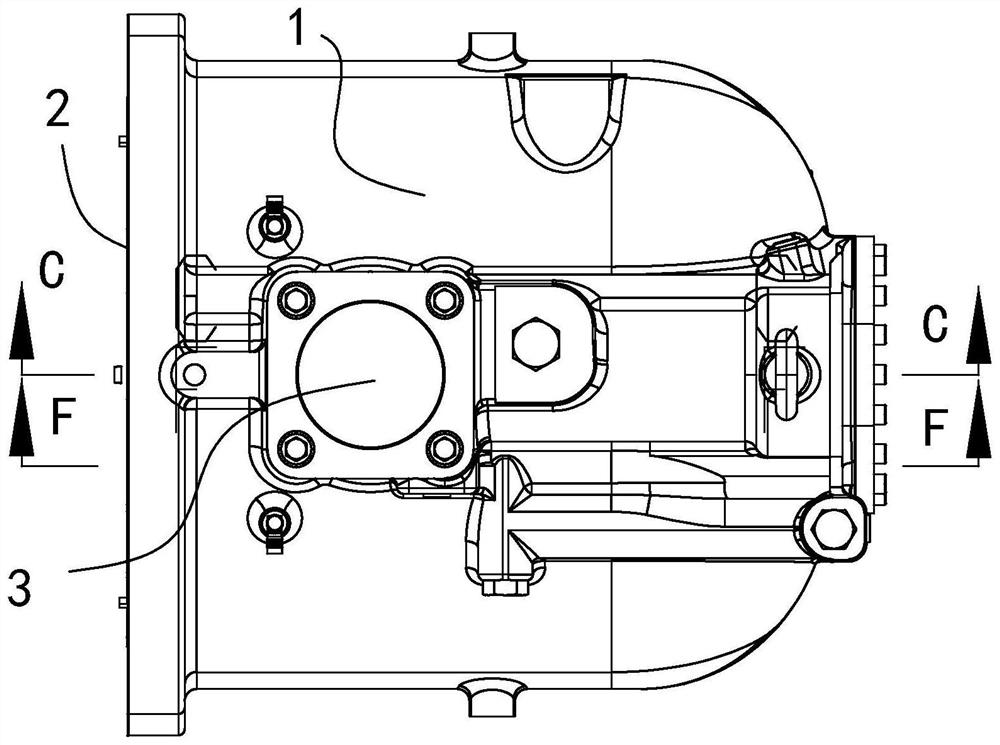

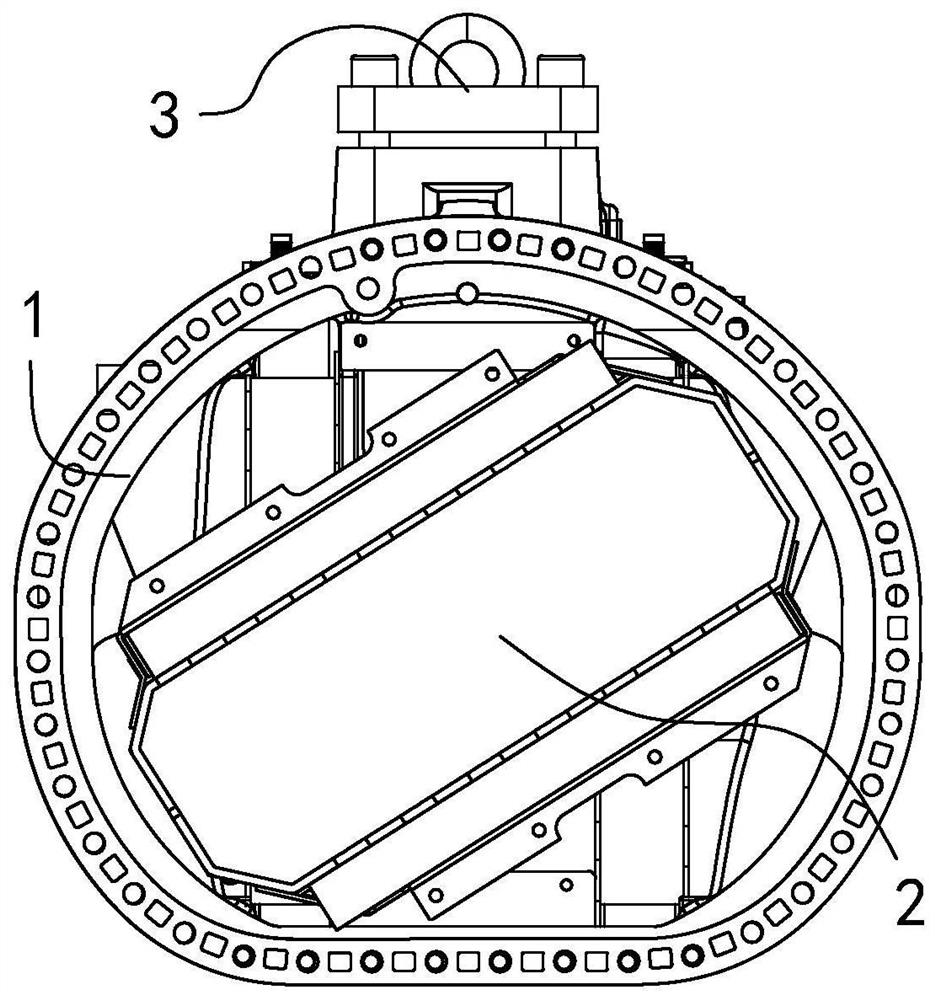

like Figure 1-8 shown, the oil separator includes an oil separator housing 1 (see figure 1 and figure 2 ), filter screen 18 and oil level monitoring device 4 (see Figure 4 ), the oil separator housing 1 forms a working space for oil and gas separation, and the oil separator housing 1 is provided with an oil separator air inlet 2 (see image 3 ) and oil separator vent 3 (see Image 6 ), the oil inlet hole 2 is communicated with the working space, the oil outlet hole 3 is communicated with the working space, and the filter screen is placed in the working space and located between the oil inlet hole 2 and the oil outlet exhaust hole 3 On the channel, the lower part of the working space is provided with an oil storage area 5 (see Image 6 ) and oil level monitoring device 4 (see Figure 4 and Image 6 ).

[0016] In order to solve the problem that the oil level of the existing oil separator is unstable due...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com