Method, device and equipment for calculating ratio of original materials and readable storage medium

A raw material and calculation result technology, which is applied in calculation, manufacturing calculation system, data processing application, etc., can solve the problem that the influence of molten iron cost cannot be considered, and the artificial experience evaluation method cannot realize fast and dynamic raw material ratio and raw material ratio. Proportioning hysteresis and other problems to achieve the effect of eliminating local optimum and global suboptimality, fast solution speed, and reduced labor costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

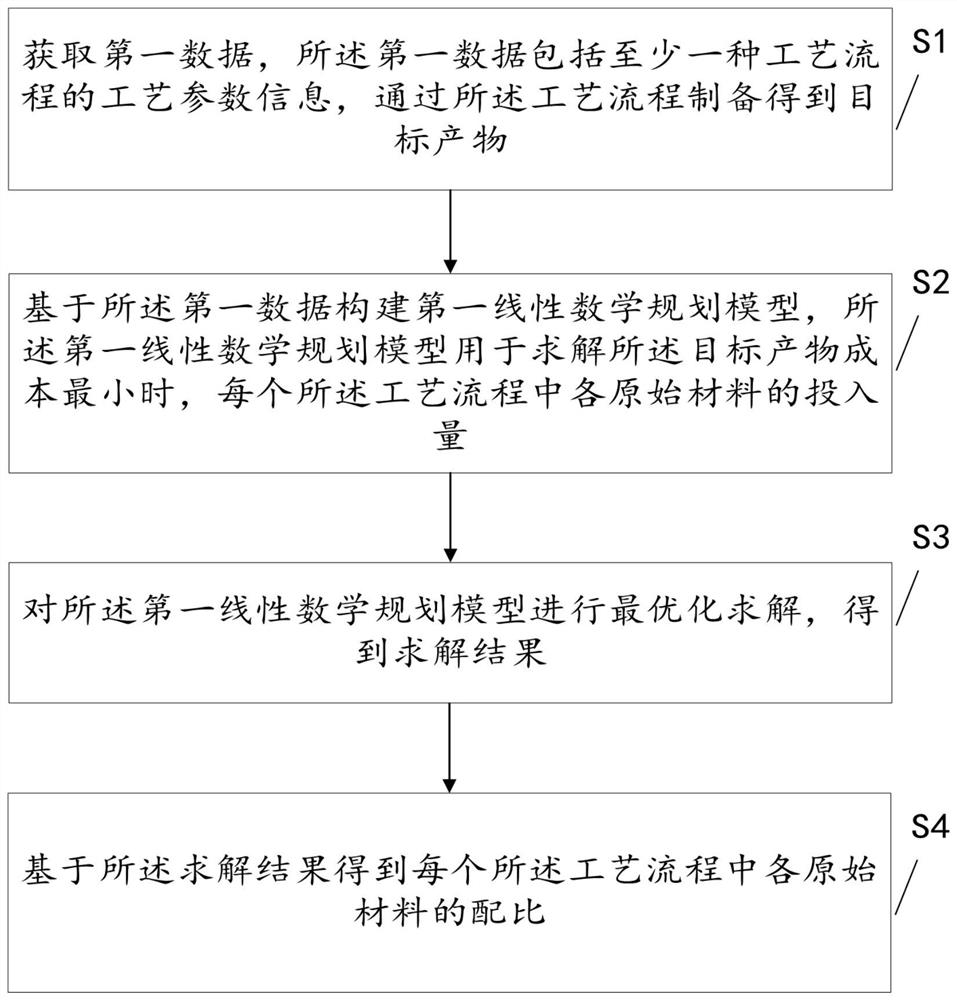

[0067] like figure 1 As shown, this embodiment provides a method for calculating the ratio of raw materials, and the method includes step S1, step S2, step S3 and step S4.

[0068] Step S1, obtaining first data, where the first data includes process parameter information of at least one technological process, and the target product is prepared through the technological process;

[0069] Step S2, constructing a first linear mathematical programming model based on the first data, and the first linear mathematical programming model is used to solve the input amount of each raw material in each of the technological processes when the cost of the target product is minimum;

[0070] Step S3, carrying out an optimal solution to the first linear mathematical programming model to obtain a solution result;

[0071] Step S4, obtaining the ratio of each raw material in each of the technological processes based on the solution result.

[0072] This embodiment proposes a linear mathematic...

Embodiment 2

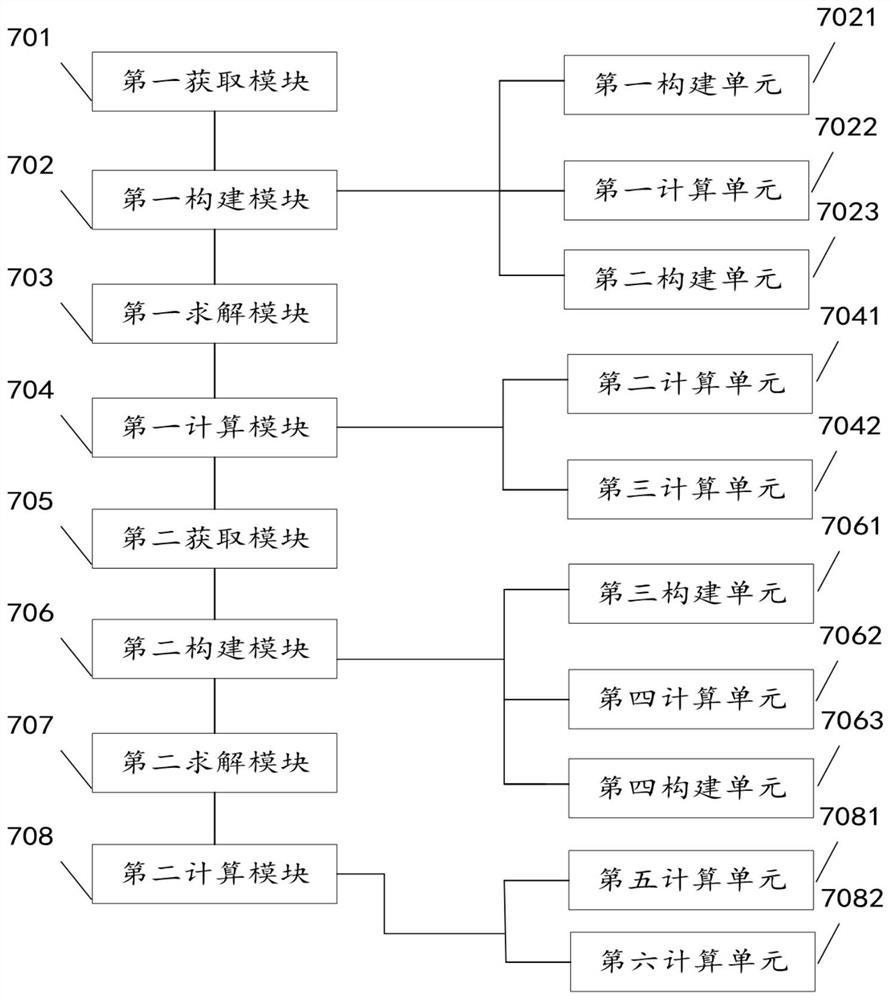

[0107] like figure 2 As shown, this embodiment provides a device for calculating the ratio of raw materials, the device includes a first acquisition module 701 , a first construction module 702 , a first solution module 703 and a first calculation module 704 .

[0108] A first acquisition module 701, configured to acquire first data, where the first data includes process parameter information of at least one process flow through which a target product is prepared;

[0109] The first building module 702 is configured to build a first linear mathematical programming model based on the first data, and the first linear mathematical programming model is used to solve the minimum cost of the target product. material input;

[0110] a first solving module 703, configured to perform an optimal solution to the first linear mathematical programming model to obtain a solution result;

[0111] The first calculation module 704 is configured to obtain the ratio of each raw material in ea...

Embodiment 3

[0133] Corresponding to the above method embodiments, the embodiments of the present disclosure also provide a device for calculating the ratio of raw materials. The device for calculating the ratio of raw materials described below and the method for calculating the ratio of raw materials described above can be referred to each other correspondingly.

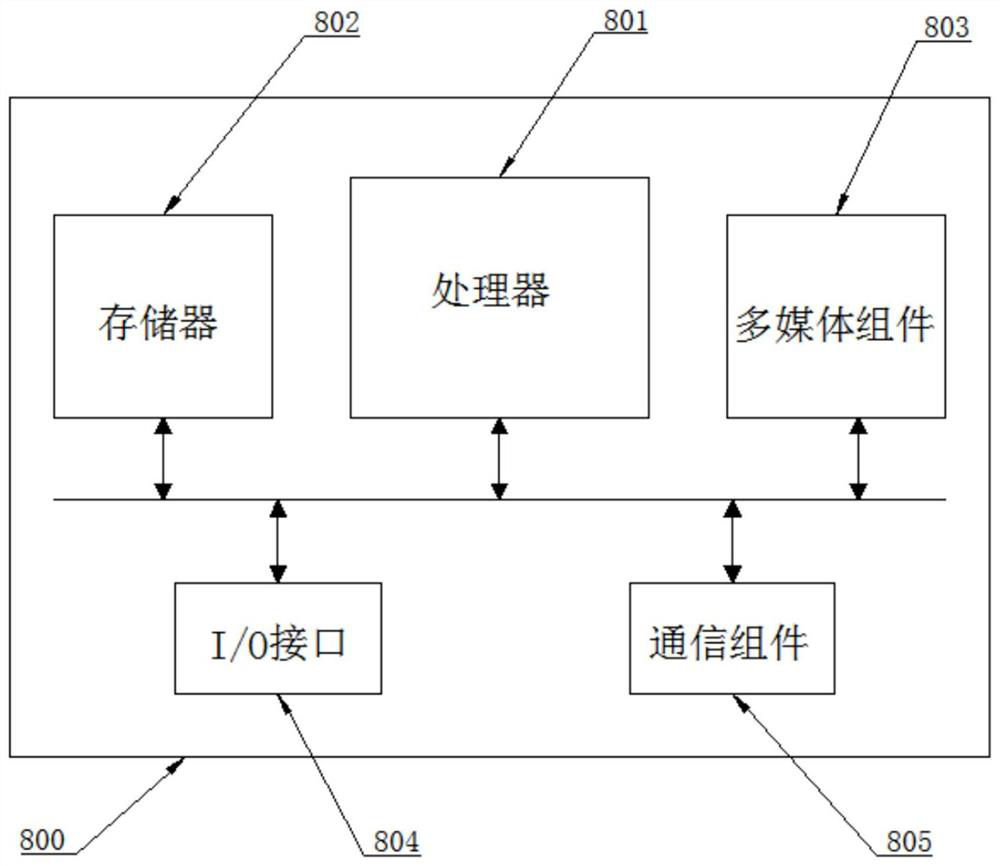

[0134] image 3 It is a block diagram of a device 800 for calculating raw material ratio according to an exemplary embodiment. like image 3 As shown, the device 800 for calculating the ratio of raw materials may include: a processor 801 and a memory 802 . The apparatus 800 for calculating raw material proportions may also include one or more of a multimedia component 803 , an input / output (I / O) interface 804 , and a communication component 805 .

[0135]The processor 801 is configured to control the overall operation of the device 800 for calculating the ratio of raw materials, so as to complete all or part of the steps in th...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap