Monomer direct-current-component-resistant magnetic core production process and equipment

A kind of production equipment and anti-DC technology, which is applied in the direction of magnetic core manufacturing, inductor/transformer/magnet manufacturing, electrical components, etc., can solve the problems of inconvenient milling slots, etc., and achieve the effect of improving applicability and scope of application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

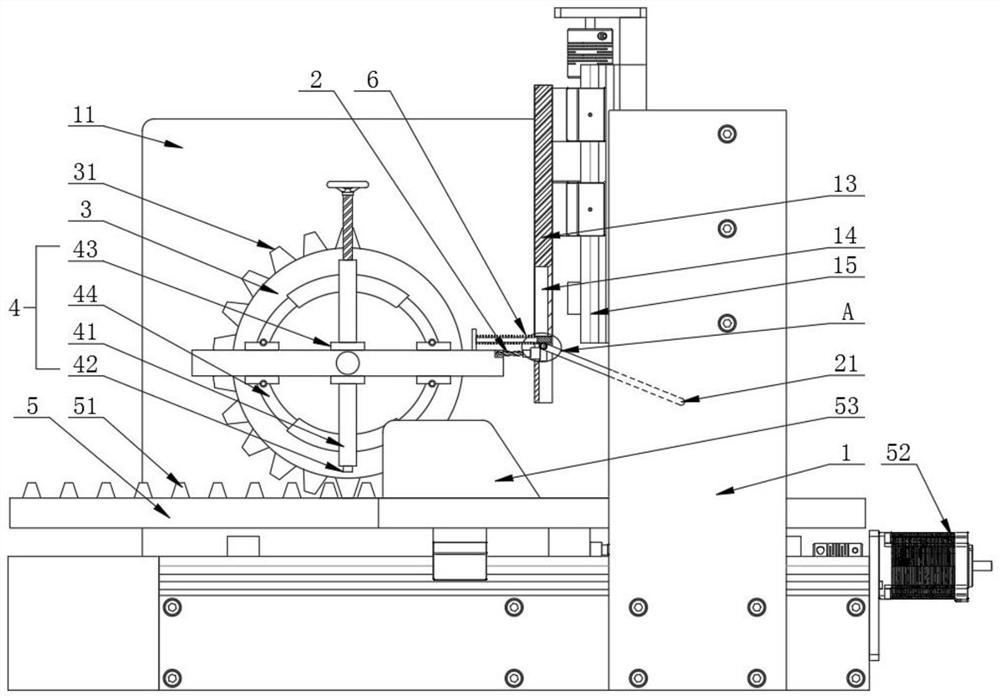

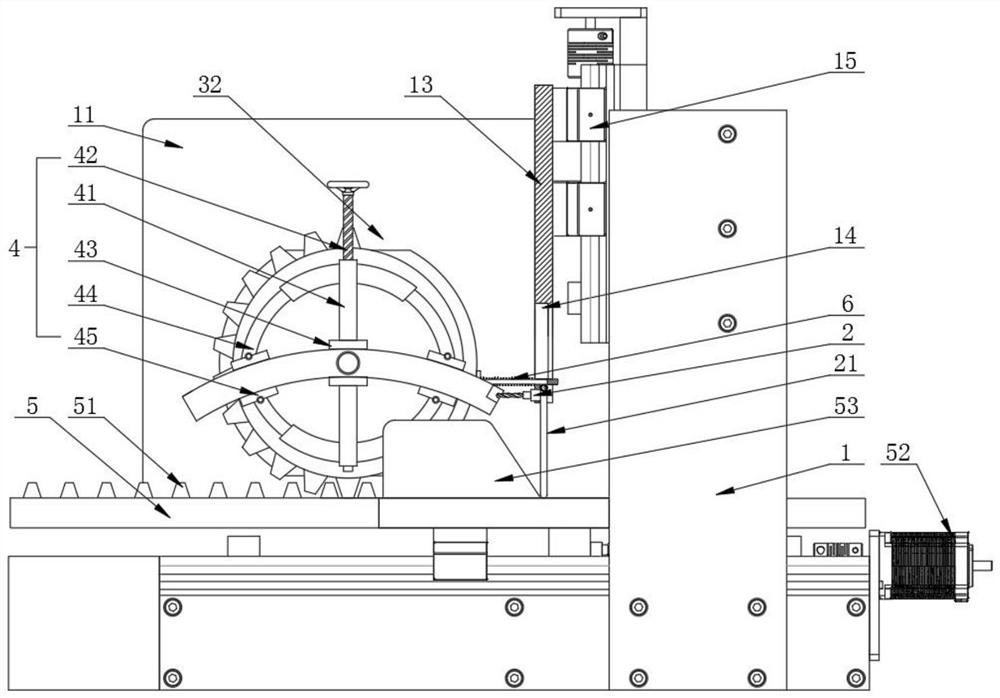

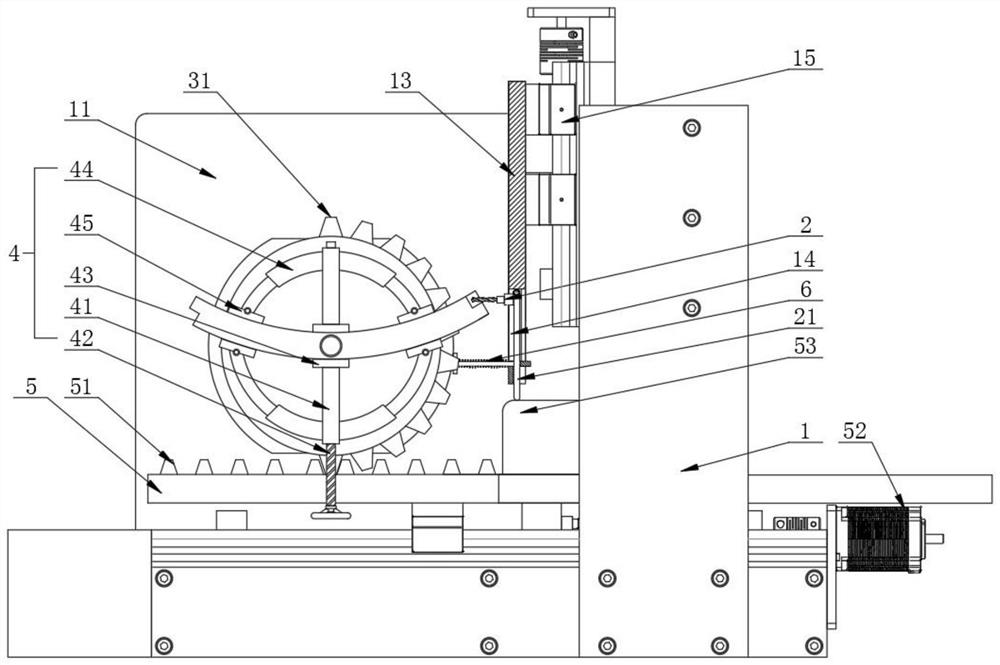

[0044] Refer to the manual attached Figure 1-Figure 12 , a single anti-DC component magnetic core production equipment, including a frame 1, the frame 1 is composed of a base and a gantry, side plates 11 are installed on both sides of the base, and the inner wall of the side plate 11 is provided with a clamp assembly 4, The gantry is provided with a cutter assembly 2, the cutter assembly 2 includes a milling cutter and a fixed seat, the milling cutter is rotatably installed on the fixed seat, the first driving part is installed on the side of the fixed seat away from the milling cutter, and the first driving part is The output end is fixedly connected with the milling cutter, the first driving member drives the milling cutter to rotate at high speed, the first driving member can be a motor or a motor, the milling cutter driving device 12 drives the fixed seat to move laterally, and the milling cutter driving device 12 can be a screw drive device or cylinder drive;

[0045] T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com