Jacquard machine with low machine body, low weight and high stability

A high-stability, jacquard machine technology, used in jacquard machines, textiles, papermaking, textiles, etc., can solve the problems of interfering with maintenance operations, low power consumption and energy saving, poor stability, etc. High stability effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

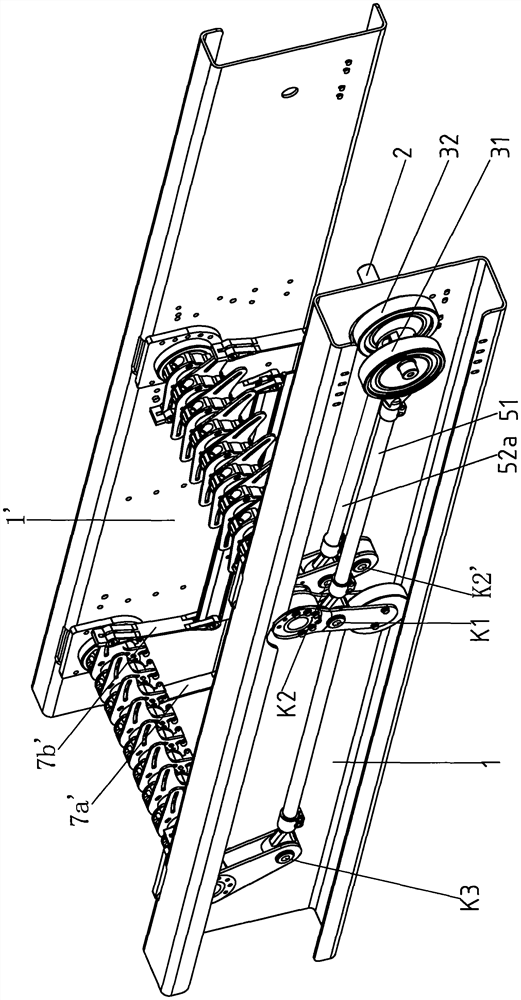

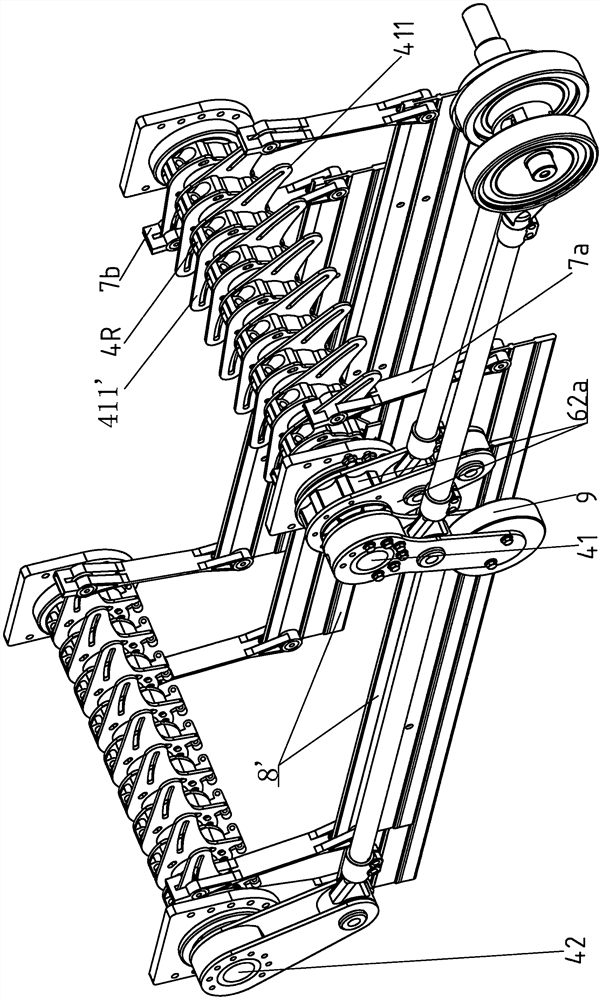

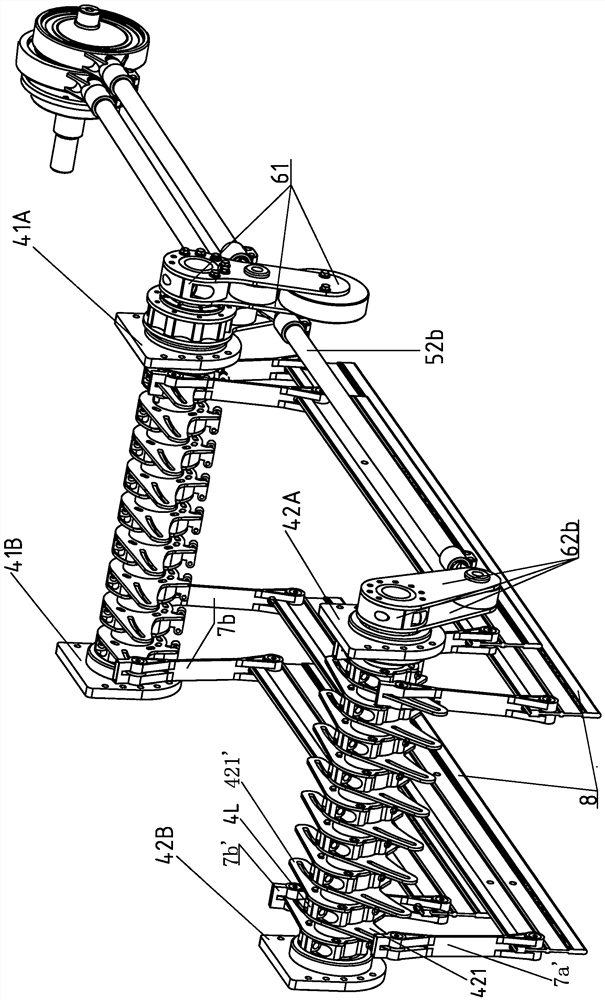

[0018] see Figure 1 to Figure 5 As shown in the figure, the jacquard machine with short body, low weight and high stability includes bottom beams (the front bottom beam 1 and the rear bottom beam 1' are shown in the figure), a longitudinal rotating shaft 2, a first longitudinal swing shaft 41 and a second Two longitudinal swing shafts 42, the longitudinal rotation shaft, the first longitudinal swing shaft and the second longitudinal swing shaft are supported on the bottom beam in sequence at intervals, and one end of the longitudinal rotation shaft 2 is spaced with a first eccentric wheel 31 whose installation angle differs by 180° (The outer eccentric wheel is shown in the figure), the second eccentric wheel 32 (the inner eccentric wheel is shown in the figure), an active fixed crank 61 and a movable crank 62a are installed at one end of the first longitudinal swing shaft 41 at intervals, and one end of the second longitudinal swing shaft 42 is installed Fixed driven crank 6...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com