Transmission mechanism for curtain sheet weaving machine

A technology of transmission mechanism and knitting machine, which is applied in looms, textiles, textiles and papermaking, etc., can solve the problems of complex structure of ply knitting machine, low processing efficiency of knitting machine, limited chain transmission speed, etc. The effect of floor space and smooth operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

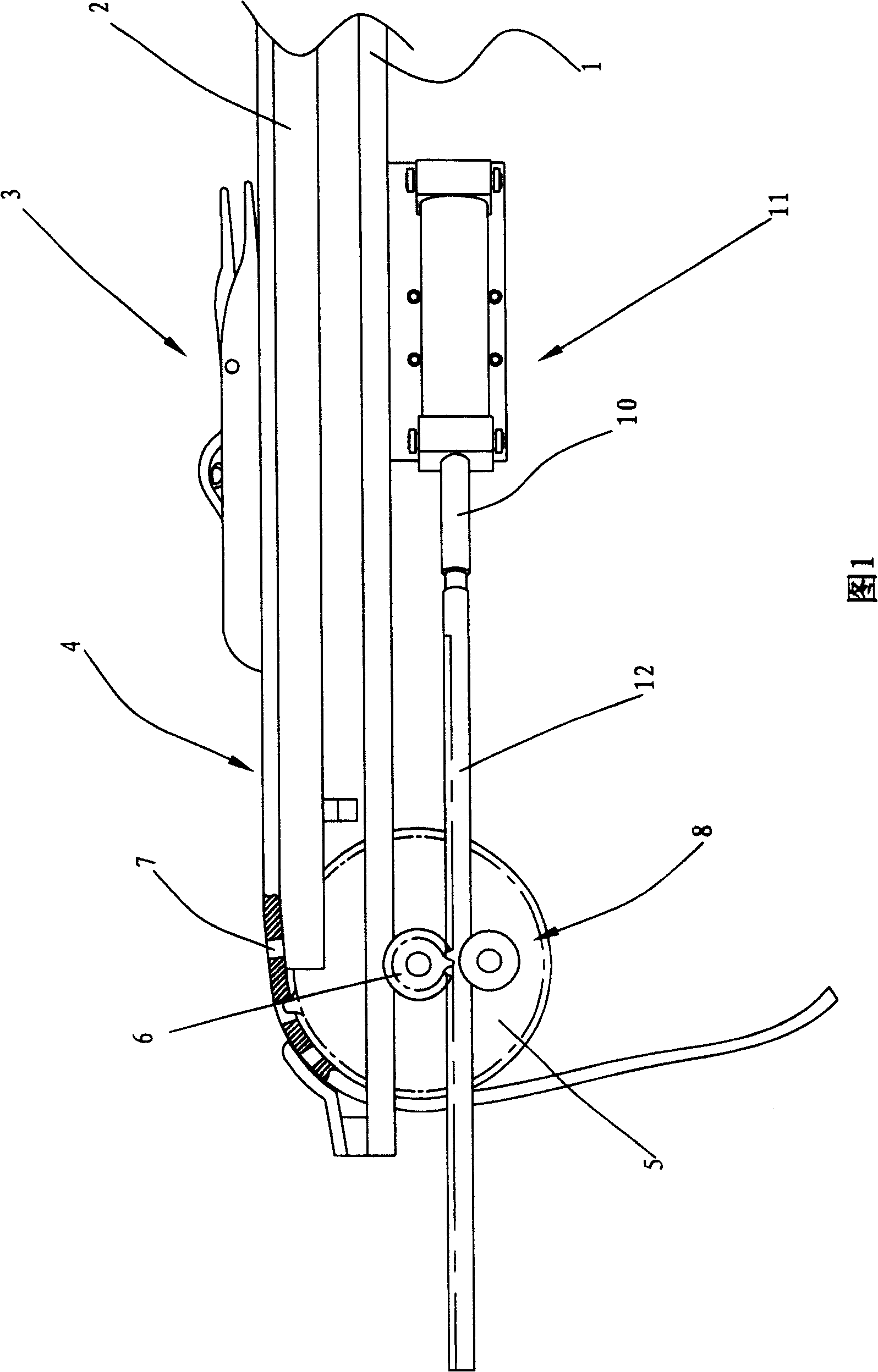

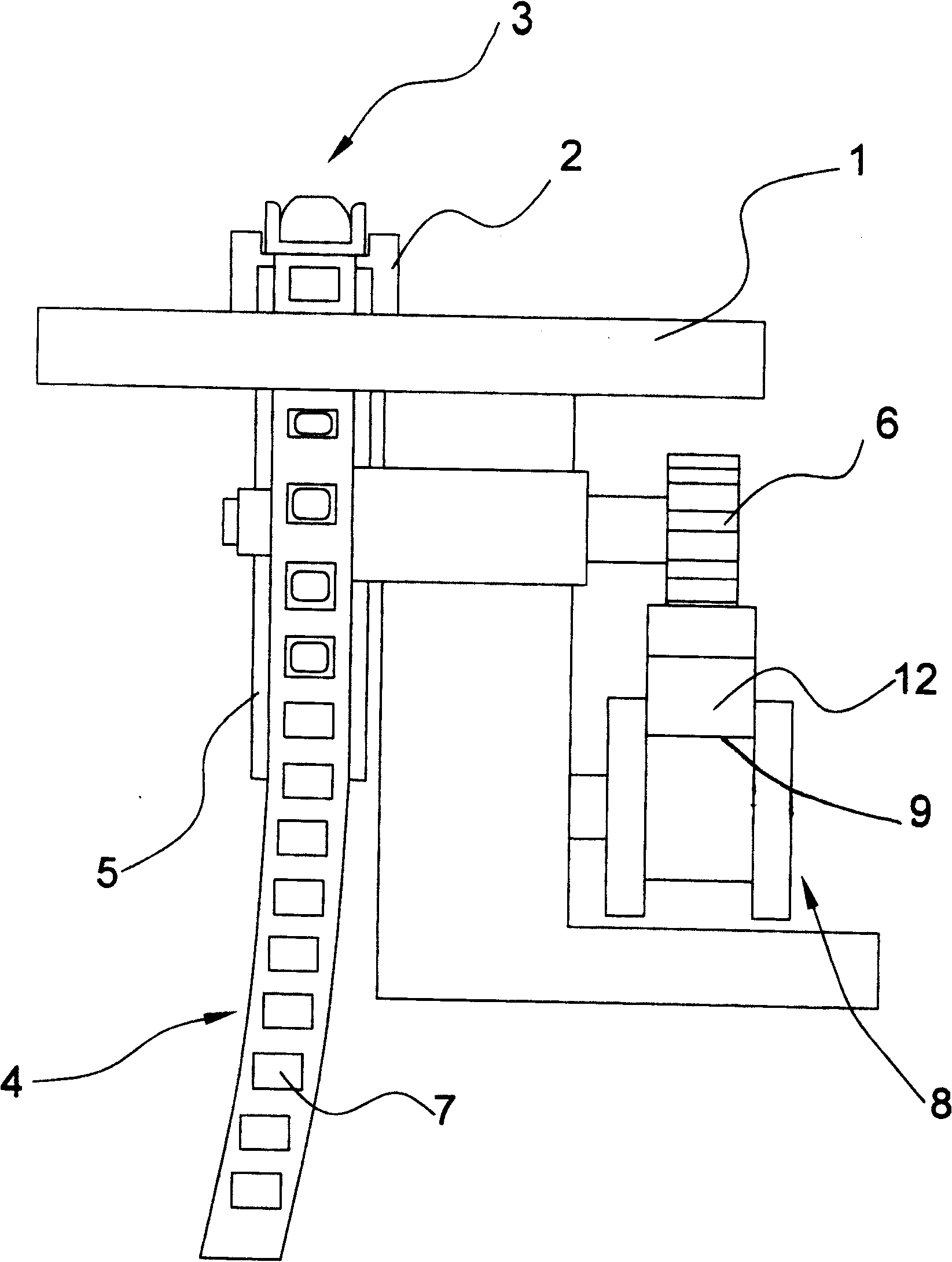

[0014] See attached drawings 1 to attached figure 2 , a transmission mechanism of a curtain knitting machine, comprising a frame 1, a guide rail 2 extending along the horizontal direction, a transmission belt 4 fixedly connected with a weaving shuttle 3 and reciprocatingly moving along the guide rail 2, on the frame 1 A first gear 5 is also rotatably provided, and the transmission belt 4 is provided with a plurality of grooves 7 along the length direction, and the transmission belt 4 partially wraps around and meshes with the first gear 5 .

[0015] A second gear 6 is coaxially fixed on the first gear 5 . Described frame 1 is also fixedly provided with cylinder 11, and described cylinder 11 has piston rod 10, and the end of described piston rod 10 is fixedly connected with rack 12, and described second gear 6 and rack 12 meshed. Below the rack 12, the frame 1 is also fixedly provided with a support wheel 8 (the positional relationship of "up" and "down" described in this spe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com