Feeding sealing and anti-blocking device and method for rotary equipment

An equipment and anti-blocking technology, applied in descaling devices, lighting and heating equipment, rotary drum furnaces, etc. Economic effect, the effect of preventing dust pollution and ensuring the smooth flow of materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

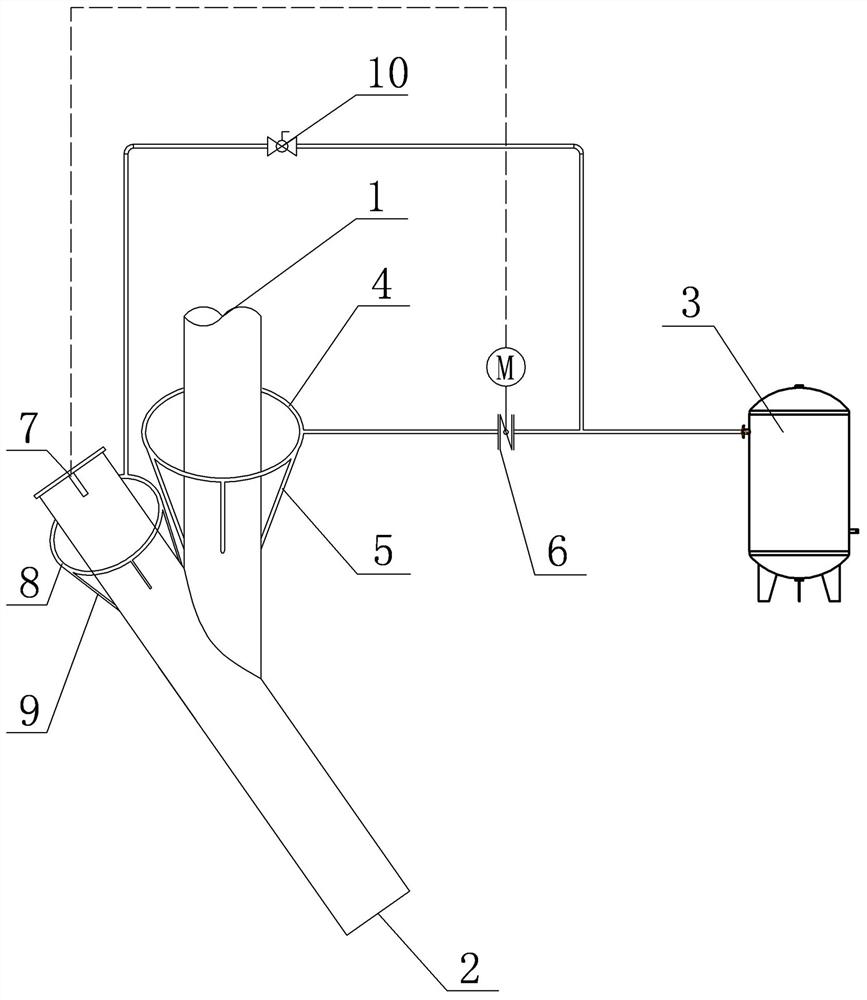

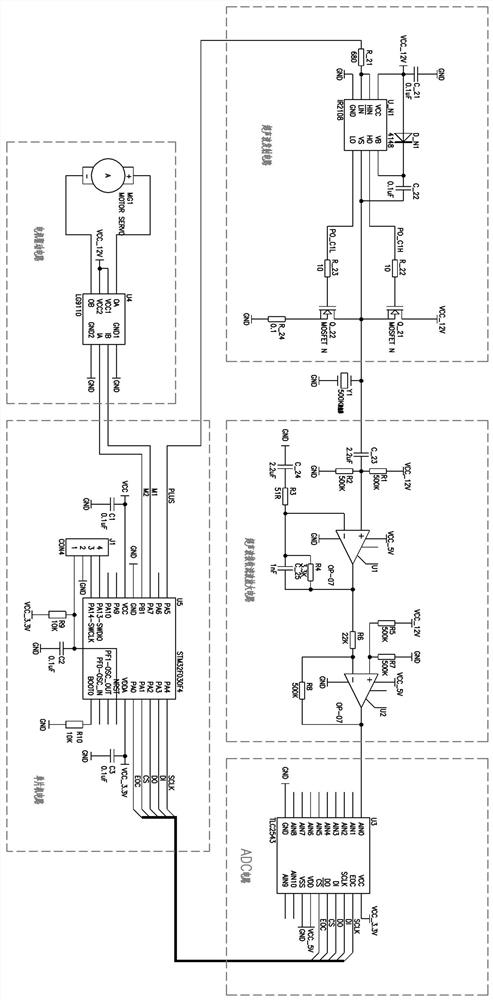

[0032] The material enters the device from the feed port 1 of the kiln chute, and leaves the device from the discharge port 2 of the kiln chute. The compressed air output from the compressed air storage tank 3 is divided into two paths, one for material purging, and the other for ultrasonic sensor purging.

[0033] In order to prevent the hot air of the rotary equipment from returning from the discharge port 2 to the feed port 1, and when the material accumulates in the kiln inlet chute, use compressed air to blow off the accumulated material, and set up a material purging pipeline. In the material purging pipeline, there are material purging loop pipe 4, material purging branch pipe 5 and electric regulating valve 6. The material purging ring pipe 4 is arranged around the vertical section of the kiln inlet chute. A plurality of material purging branch pipes 5 are evenly connected in the circumferential direction of the material purging ring pipe 4, and the material purging br...

Embodiment 2

[0037] Embodiment 2: This embodiment is basically the same as Embodiment 1, and the similarities will not be repeated. The difference is that the function can be cut and selected according to different usage conditions and cost requirements of the kiln chute, and the use occasions can be expanded. For example, if the material pollution is not serious, the ultrasonic sensor may not be installed to purge the pipeline.

[0038] Of course, the manual regulating valve 10 can also be changed to an electric control valve, which is selected according to the actual situation, and will not be described in detail.

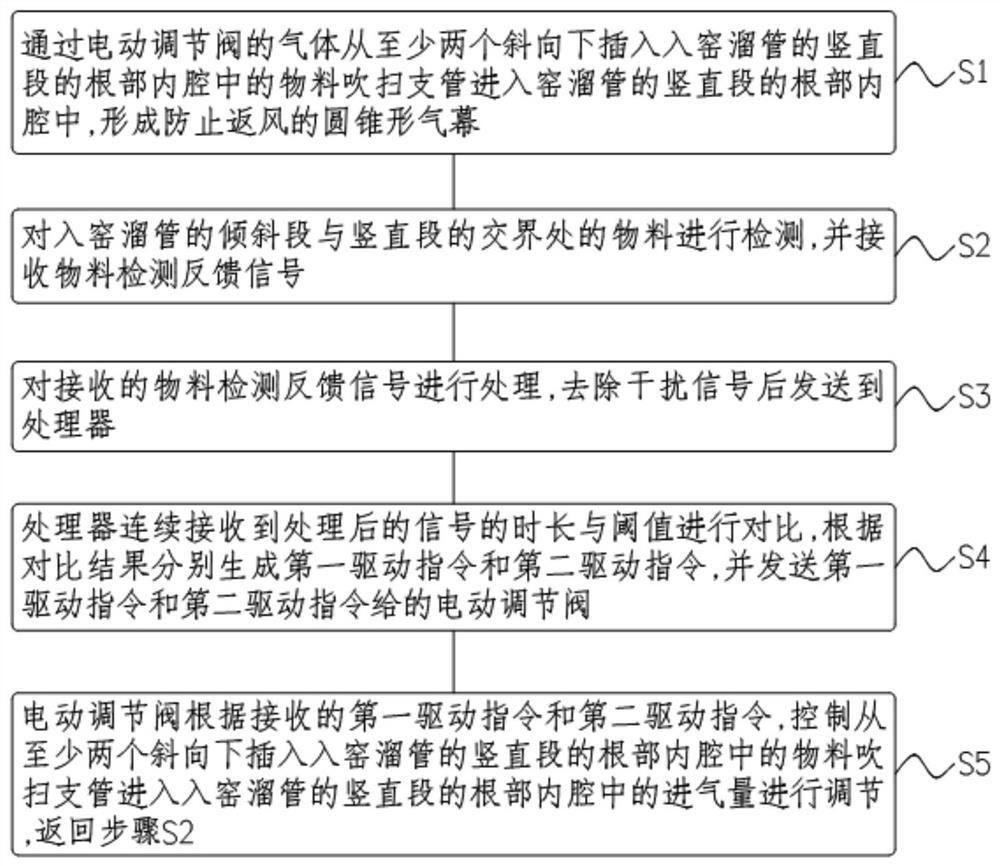

[0039] see Figure 1-Figure 3, the present application discloses a method for sealing and anti-blocking of the feed of the rotary equipment. In step S1, the gas passing through the electric regulating valve 6 is inserted into the inner cavity of the root of the vertical section of the kiln chute from at least two oblique downwards. The purging branch pipe 5 enters the inner ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com