System and associated method for detecting leaks

A leak detection, technology-under-test, applied to systems and associated fields for detecting leaks, capable of solving problems of leak measurement results, difficult to implement, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

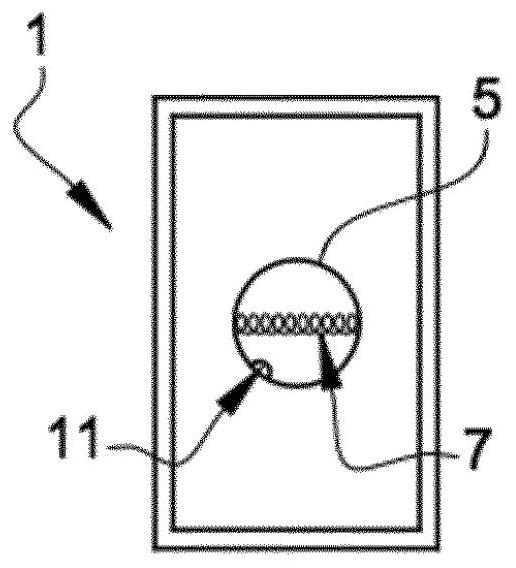

[0064] figure 2 is a very schematic representation of a detection system 20 according to the invention in a first application example, wherein said leak detection system 20 is Figure 1a to Figure 1c Used on cartridge 1 as described.

[0065] Thus, the system 20 includes:

[0066] - a test chamber 22 configured to accommodate the components to be tested, here the cartridge 1 (represented very schematically);

[0067] - means 24 adapted to vary the pressure in said test chamber 22;

[0068] - a measuring device 26 for measuring a physical quantity indicative of the level of leakage, such as a pressure gauge or a flow meter;

[0069] - an insert 28 (or connecting part) configured to cooperate with the area of the cartridge 1 containing the permeable area.

[0070] Thus, the insert 28 is inserted into the suction tube 5 of the cartridge 1 via one end of the tube, while the other end of the tube is sealed by a sealing member, such as a cap.

[0071] like figure 2 As show...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap