Self-protection type hydraulic equipment

A technology of hydraulic equipment and self-protection, which is applied in safety equipment, metal processing equipment, using stable tension/pressure to test the strength of materials, etc., to improve safety and realize the effect of self-protection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

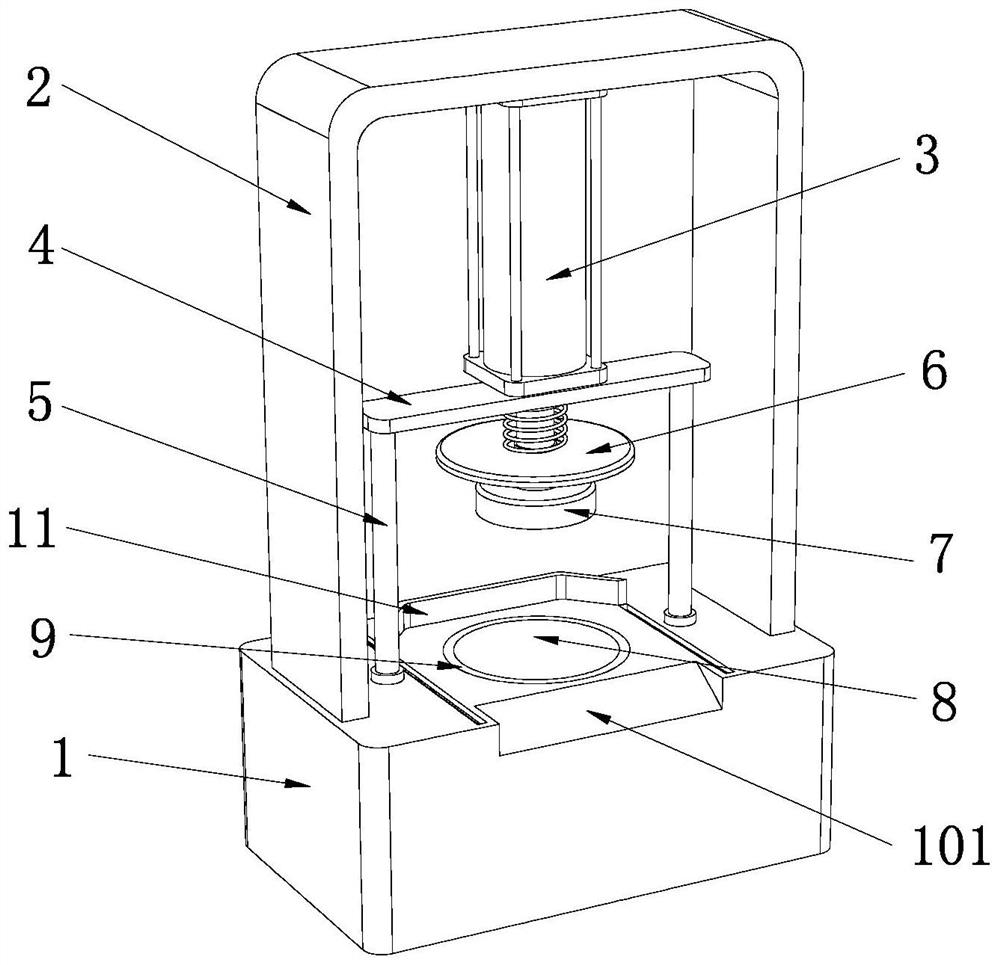

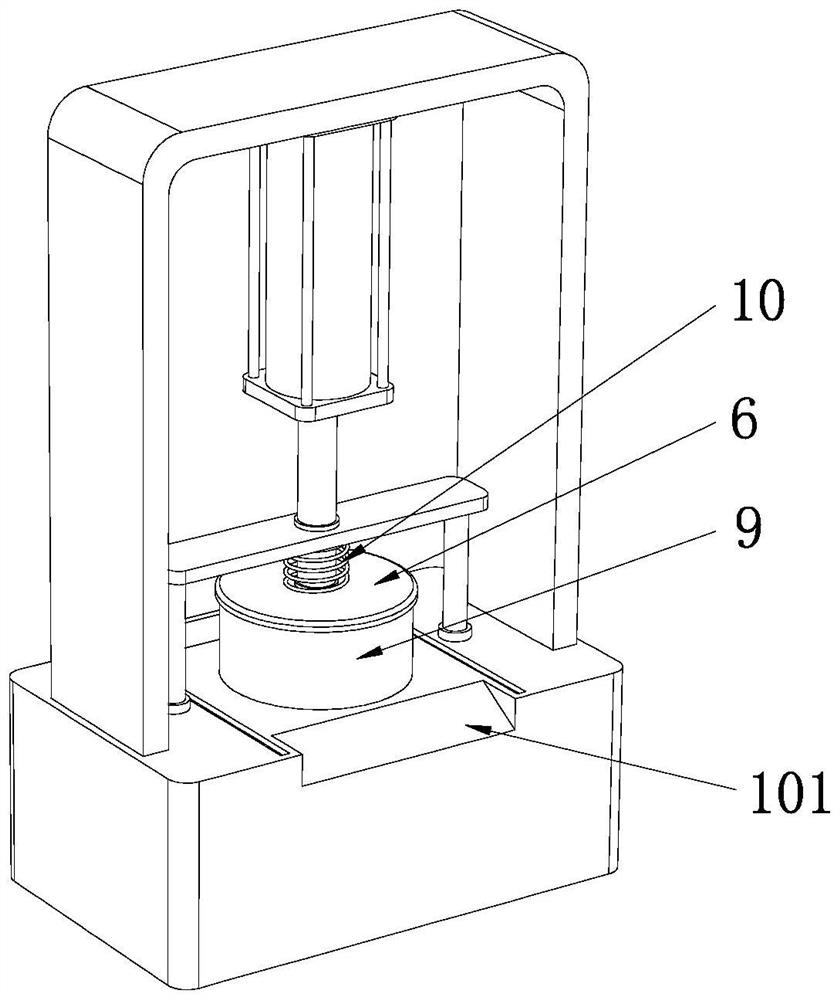

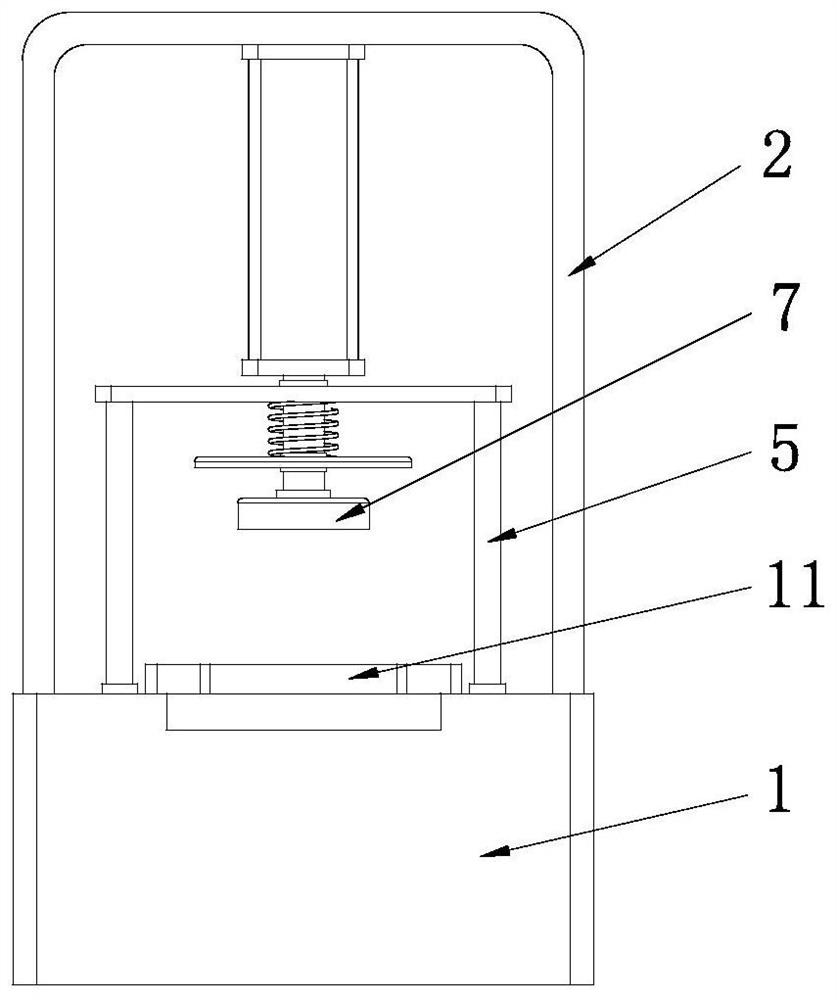

[0028] The working principle of the present invention is: when using, the workpiece is first placed on the support platform 8, and then the output end of the hydraulic cylinder 3 is controlled to stretch out. When the output end of the hydraulic cylinder 3 stretches out, the pressure plate 7 is gradually driven to move towards the support platform 8, thereby Gradually squeeze the workpiece, so as to carry out the compression test on the workpiece, or stamp the workpiece. When the pressing plate 7 moves downward, the transmission mechanism drives the protective cylinder 9 to move upward, thereby gradually enclosing the workpiece in the protective cylinder 9 In order to avoid the fragments of the workpiece from splashing out and hitting the hydraulic equipment during the pressurization process, so as to realize the self-protection of the hydraulic equipment; when the guide post 5 moves toward the guide groove 102, the guide post 5 drives the nut 13 to move downward gradually, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com