Integrated detection method for contour and hole position of automobile part

An auto parts and integrated detection technology, applied in the detection field, can solve the problems of poor detection effect, long time, affecting production efficiency, etc., and achieve the effect of improving detection quality and reducing workload

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] It should be noted that like numerals and letters refer to like items in the following figures, so once an item

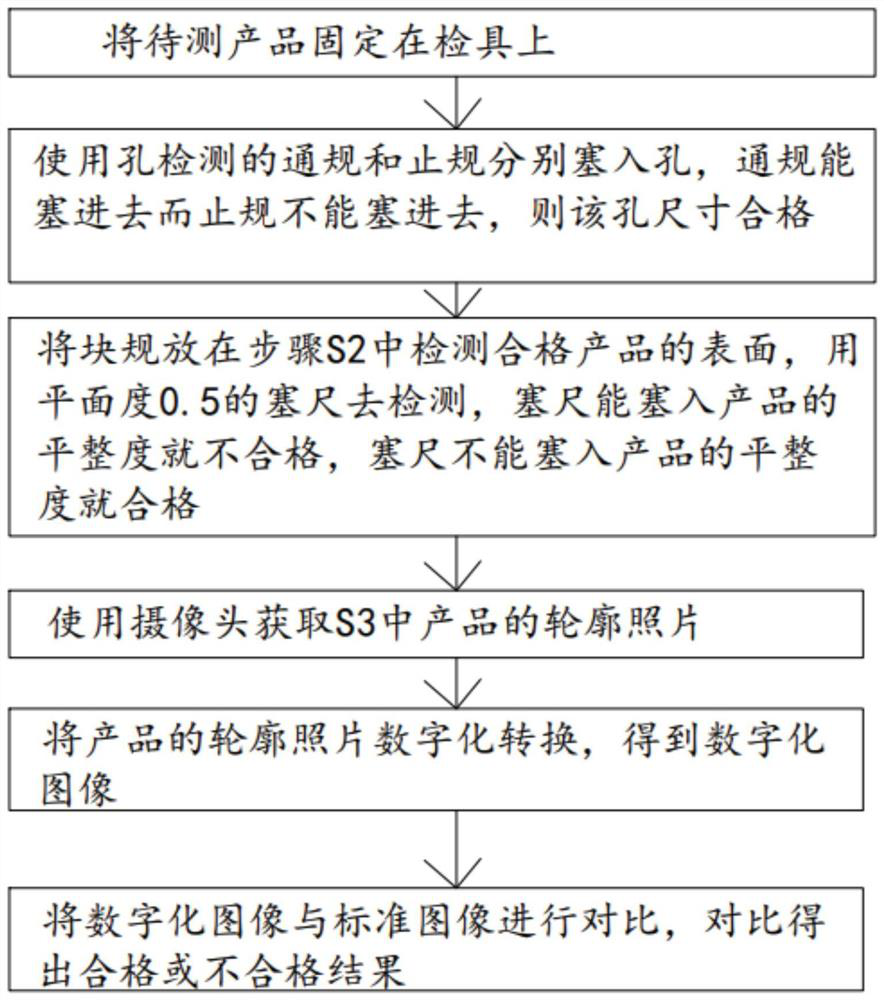

[0041] S6: the digitized image is compared with the standard image, and the comparison draws a qualified or unqualified result.

[0045] The coordinates of the product cloud map take the geometric center point of the product cloud map as the coordinate origin. This makes it easy to calculate the hole to the original coordinate

[0048] The detection environment in step S1 is a dust-free environment. External influences can be reduced.

[0049] Before performing step S1, the appearance of the product is detected, and the severely deformed product is rejected. Can be reduced

[0050] Carry out step S2 to the need to check the general rule and the stop rule. It can reduce the influence caused by the error of the pass and stop

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com