Method for additive construction of shaped bodies by stereolithography

A technology of stereolithography and forming bodies, which is applied in the direction of additive processing, 3D object support structure, metal processing equipment, etc., and can solve the problems of time-consuming and transportation time-consuming

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

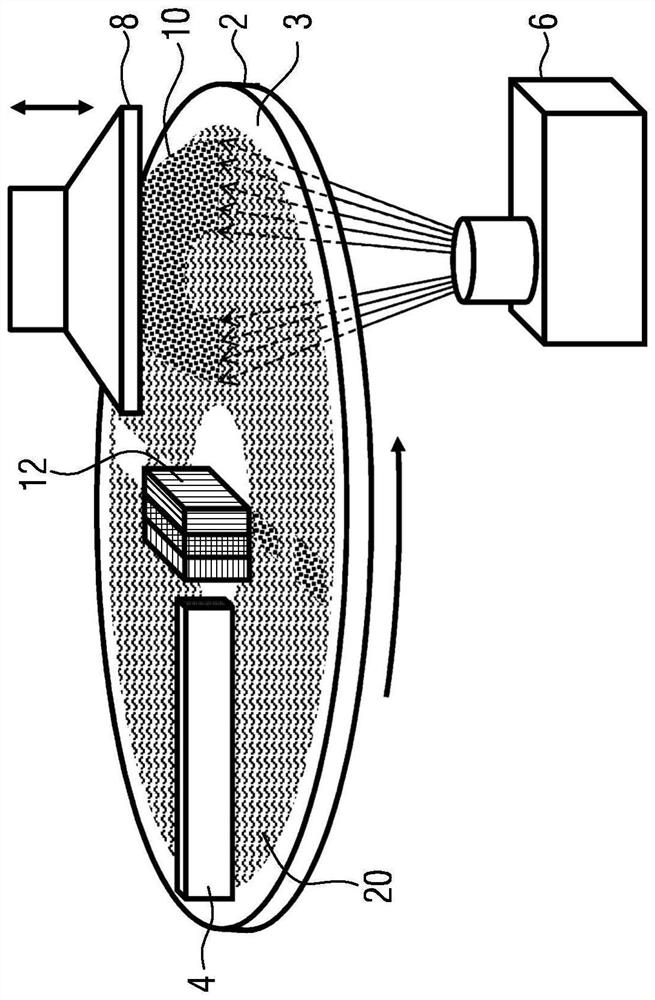

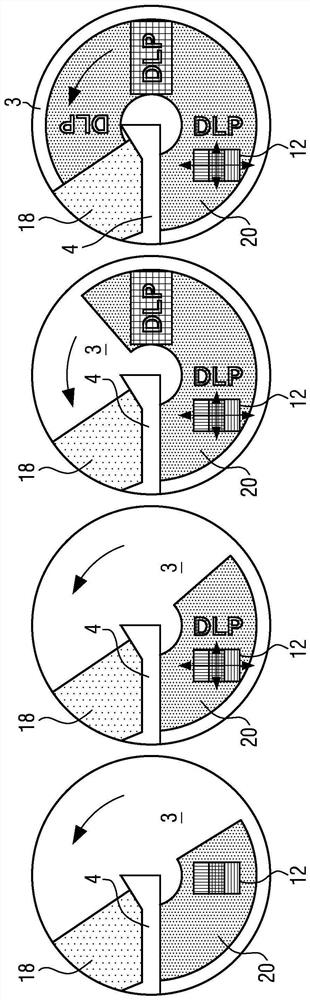

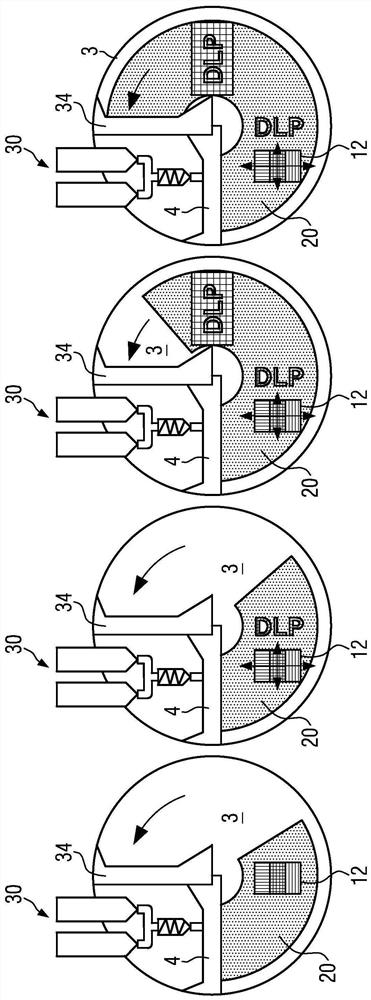

[0051] figure 1 A highly simplified schematic perspective view of the essential components of the apparatus for carrying out the method according to the invention is shown. The apparatus comprises a rotatable tub 2, shown for reasons of simplicity as a disk-shaped bottom 3 without the side walls actually surrounding the disk. The barrel bottom 3 is transparent at least in the region in which the exposure unit 6 is exposed to the build-up area. Opposite the exposure unit 6 , a vertically movable build platform 8 is arranged above the barrel bottom 2 . The part 10 being constructed is suspended on the build platform 10 .

[0052] The scraper 4 is suspended above the tub bottom 3 in a position-adjustable manner. The tub 2 is rotatable about a vertically extending axis of rotation extending from the center of the disk of the horizontal tub bottom 3 . A rotary drive (not shown) is provided which rotates the tub 2 under the control of a control unit (not shown) and stops the tub...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap