Novel armature assembly for relay

A relay and armature technology, applied in the field of armature components for new relays, can solve the problems of inability to contact with static contacts, inability to drive moving reeds to rotate, and relays not working normally, so as to avoid inability to contact, change reset capability, reduce The effect of a small overall volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

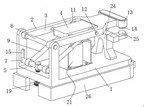

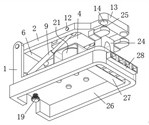

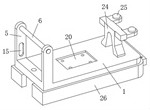

Image

Examples

Embodiment Construction

[0029] Secondly, the lower ends of the inner walls on both sides of the through groove 5 are vertically provided with chute 15, and the two ends of the movable shaft 7 are respectively located in the inner cavities of the two chute 15 and are adapted to the chute 15, and the movable shaft 7 can move along the The longitudinal direction of the chute 15 slides up and down. When the movable shaft 7 slides up and down in the vertical direction, it can adjust the inclination angle of the elastic telescopic rod 9, thereby adjusting the return spring embedded in the elastic telescopic rod 9 to move the reed 2 The amount of thrust generated.

[0030]Further, a connecting sleeve 16 is fixedly connected to the middle of the movable shaft 7, and the inner cavity of the connecting sleeve 16 is movably connected with a connecting column 171, and the lower end of the connecting column 171 is fixedly connected with an adjusting rod 17, and the outside of the adjusting rod 17 is provided with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com