A large motor stator coil bending equipment

A technology of stator coils and large motors, applied in the manufacture of motor generators, electromechanical devices, electrical components, etc., can solve problems such as incomplete bending, low work efficiency, and secondary bending required by users, and achieve improved bending Efficiency, the effect of improving the bending effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be described in detail below with reference to the various embodiments shown in the accompanying drawings. However, these embodiments do not limit the present invention, and the structural, method, or functional transformations made by those of ordinary skill in the art based on these embodiments are all included in the protection scope of the present invention.

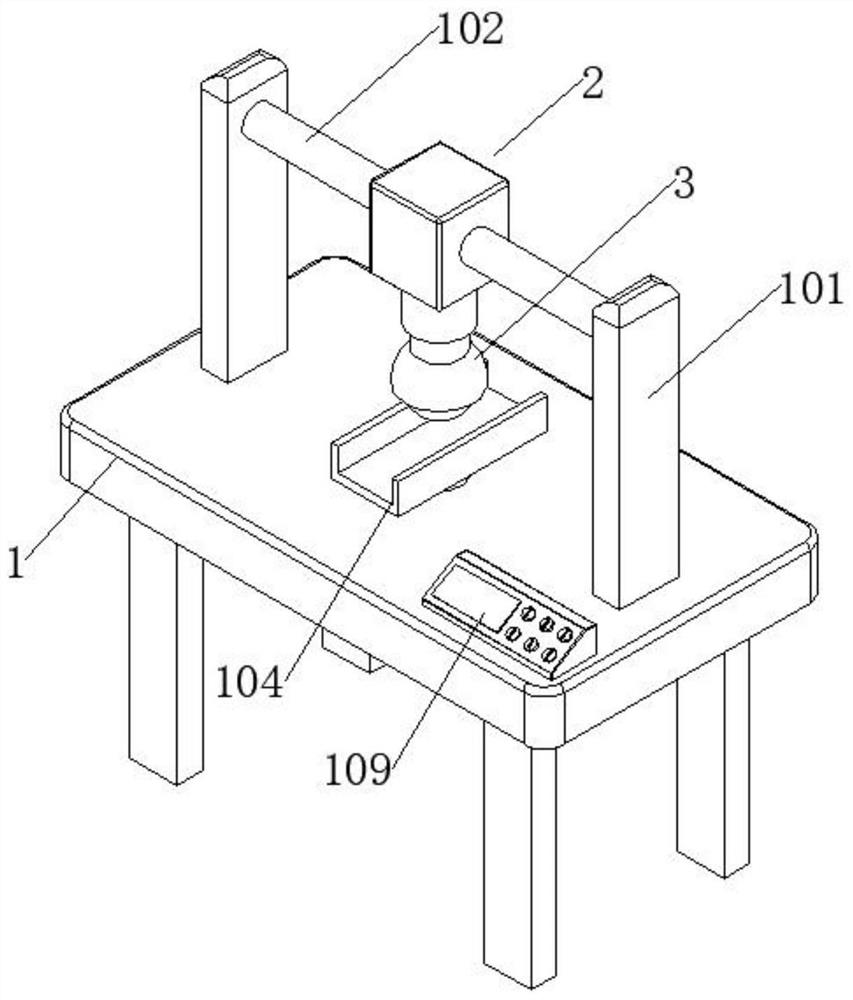

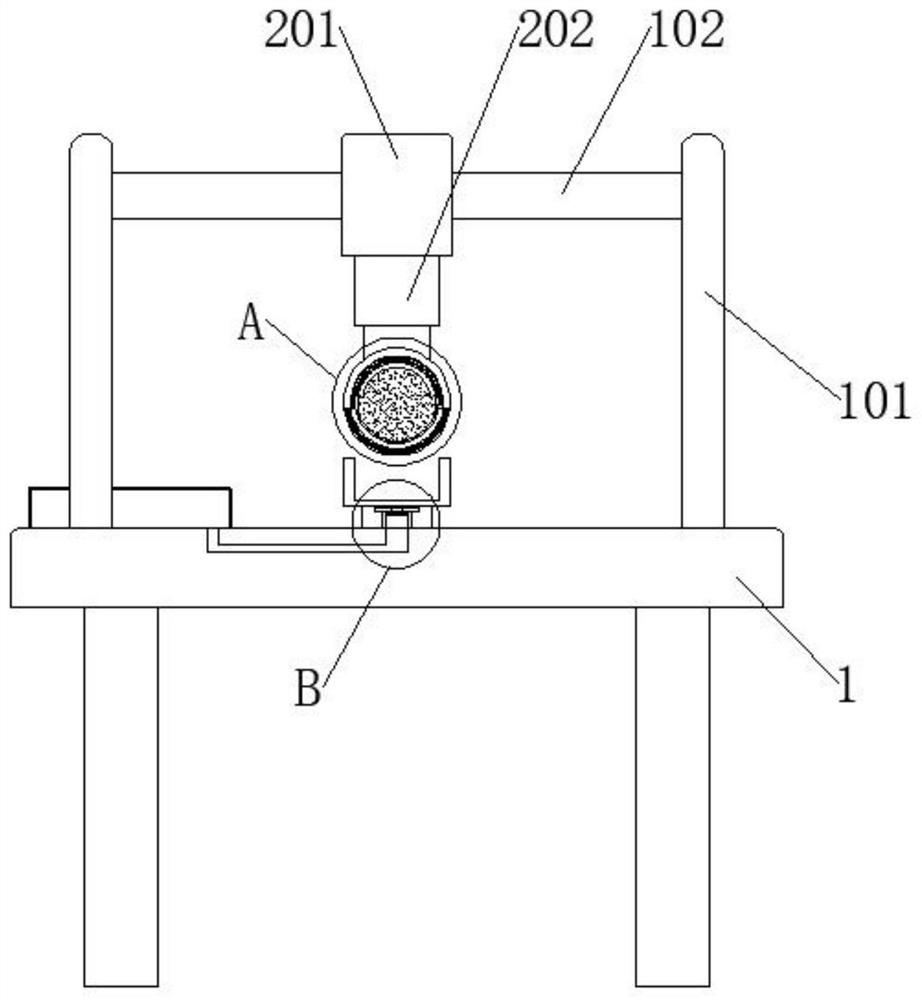

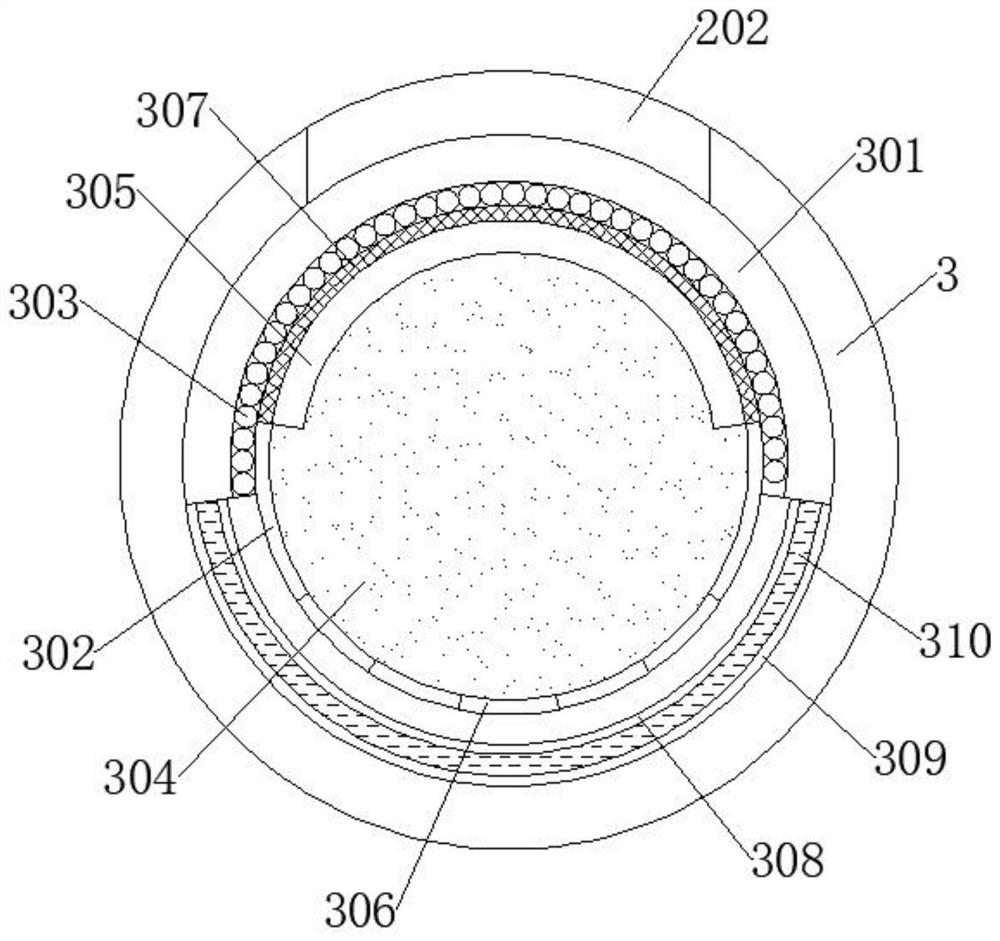

[0028] The invention discloses a large-scale motor stator coil bending equipment. Figure 1-Figure 4 As shown, it includes a worktable 1 , a curved extrusion mechanism 2 mounted on the worktable 1 , a multi-variable curved mechanism 3 for bending, and a suction cup 4 .

[0029] ginseng Figure 1-Figure 2 As shown, a pair of brackets 101 are installed on the worktable 1, a fixed rod 102 is connected between the pair of brackets 101, and a curved extrusion mechanism 2 is installed on the fixed rod 102, and the curved extrusion mechanism 2 is used to drive the multi-variable The bendi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com