Plunger type reciprocating pump with multi-loop hydraulic combination

A plunger-type, multi-circuit technology, applied in variable-capacity pump components, liquid-variable-capacity machinery, and cleaning methods using liquids, etc., can solve the leakage of sealing structures, accelerated wear of plungers and packings, and unfavorable environmental safety, etc. problems, to achieve the effect of improving sealing, improving service life and preventing leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

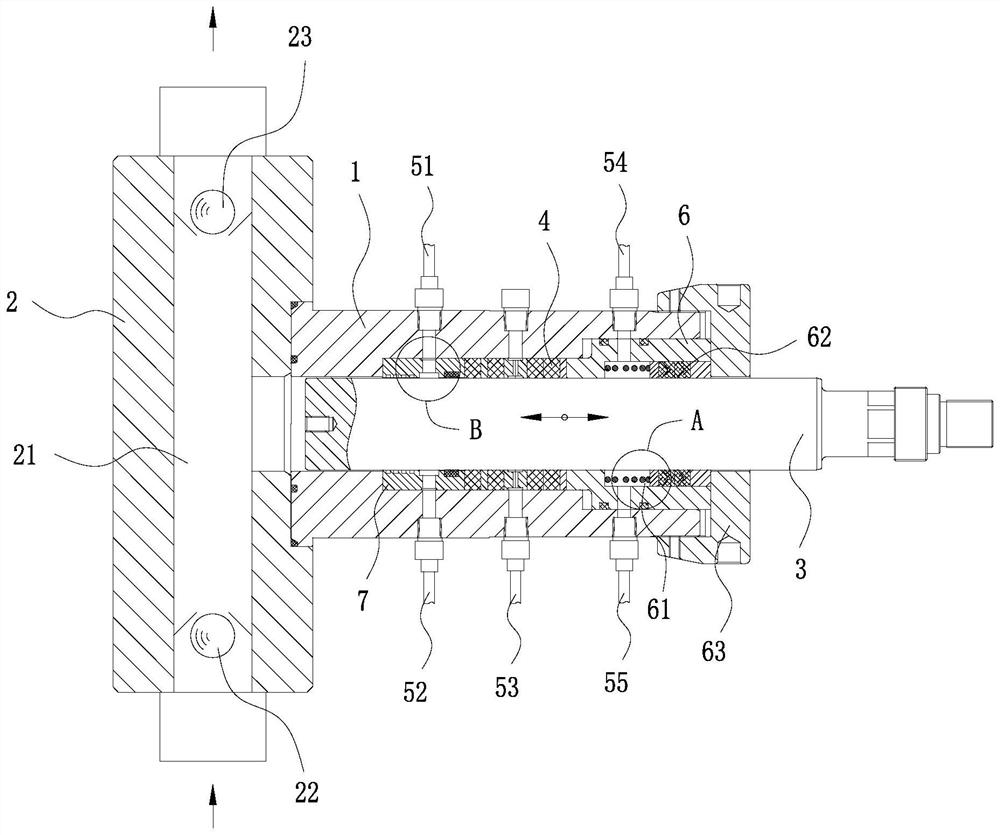

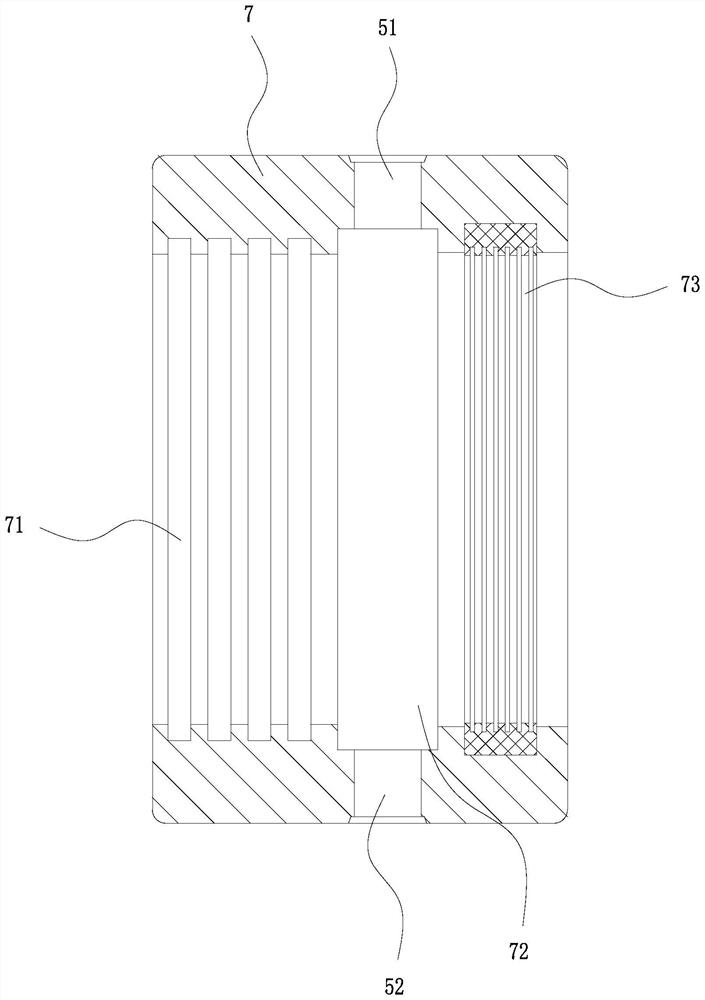

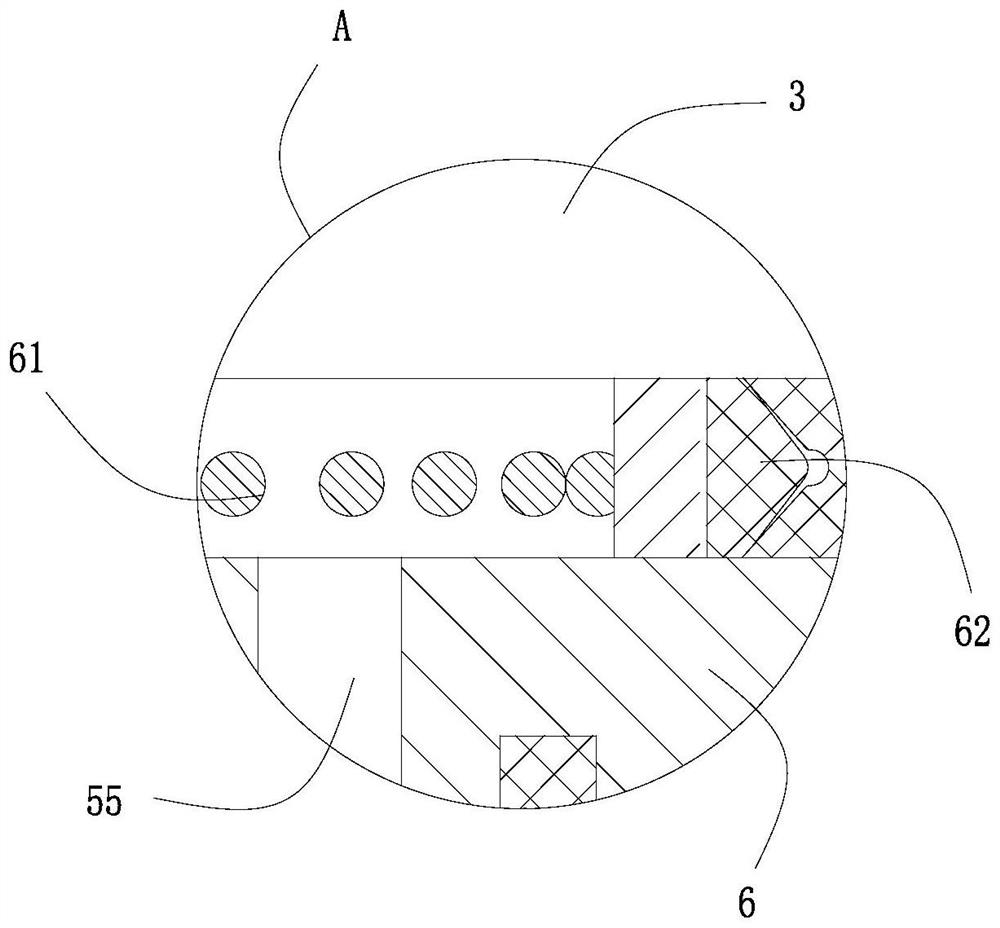

[0030] like Figure 1 to Figure 4 As shown, this embodiment shows a plunger type reciprocating pump with a multi-circuit hydraulic combination, including a pump body 2, a cylinder liner 1 and a plunger 3 arranged in the cylinder liner 1, the plunger 3 along the cylinder liner 1. Sliding in the longitudinal direction, the pump body 2 is provided with a pump cavity 21, the two ends of the pump body 2 are respectively provided with an inlet 22 and an outlet 23, and the cylinder liner 1 is provided with a sealing assembly 4 and a compression sleeve 6, The sealing assembly 4 is provided with a sealing sleeve 7 on the side close to the pump body 2, the outer peripheral wall of the plunger 3 is located in the sealing assembly 4, the pressing sleeve 6 and the sealing sleeve 7, and one end of the cylinder sleeve 1 is provided with a sealing sleeve 7. On the adjusting nut 63 of the adjusting pressing sleeve 6 , the end of the cylinder sleeve 1 is provided with a thread that matches the ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap