Solder paste printing visual detection system and method based on SPI detection algorithm

A visual inspection and solder paste printing technology, which is applied in the field of solder paste printing visual inspection system, achieves the effects of high precision, quality assurance, and high work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The embodiments of the present invention will be specifically described below with reference to the accompanying drawings, which are for reference and illustration purposes only, and do not limit the scope of the patent protection of the present invention.

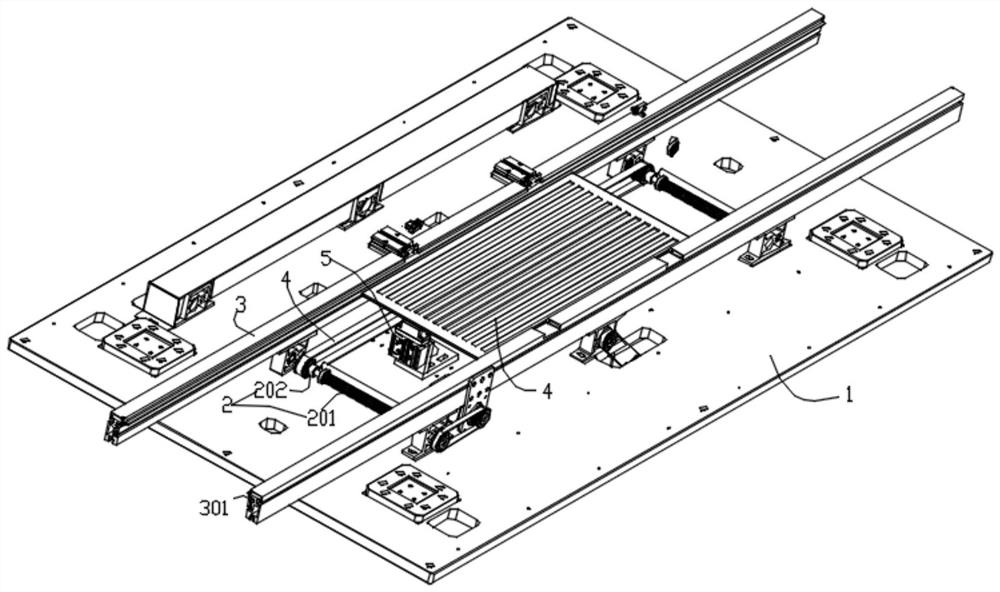

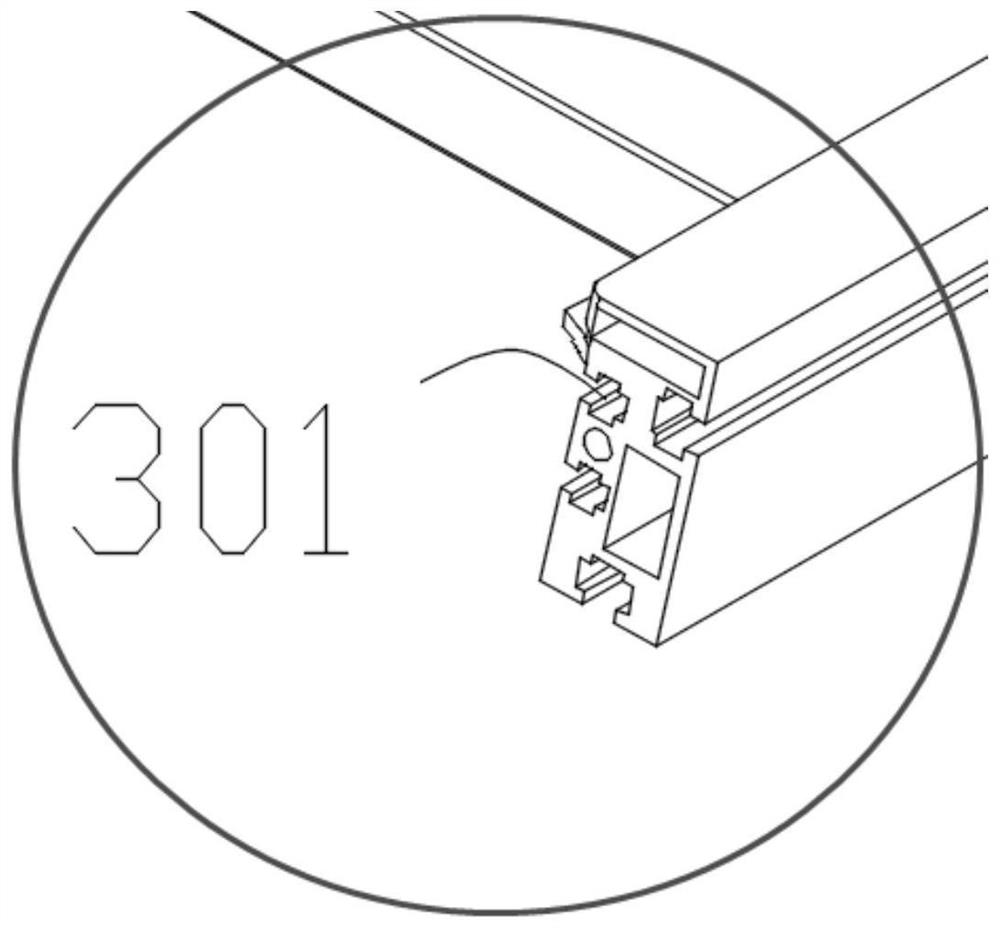

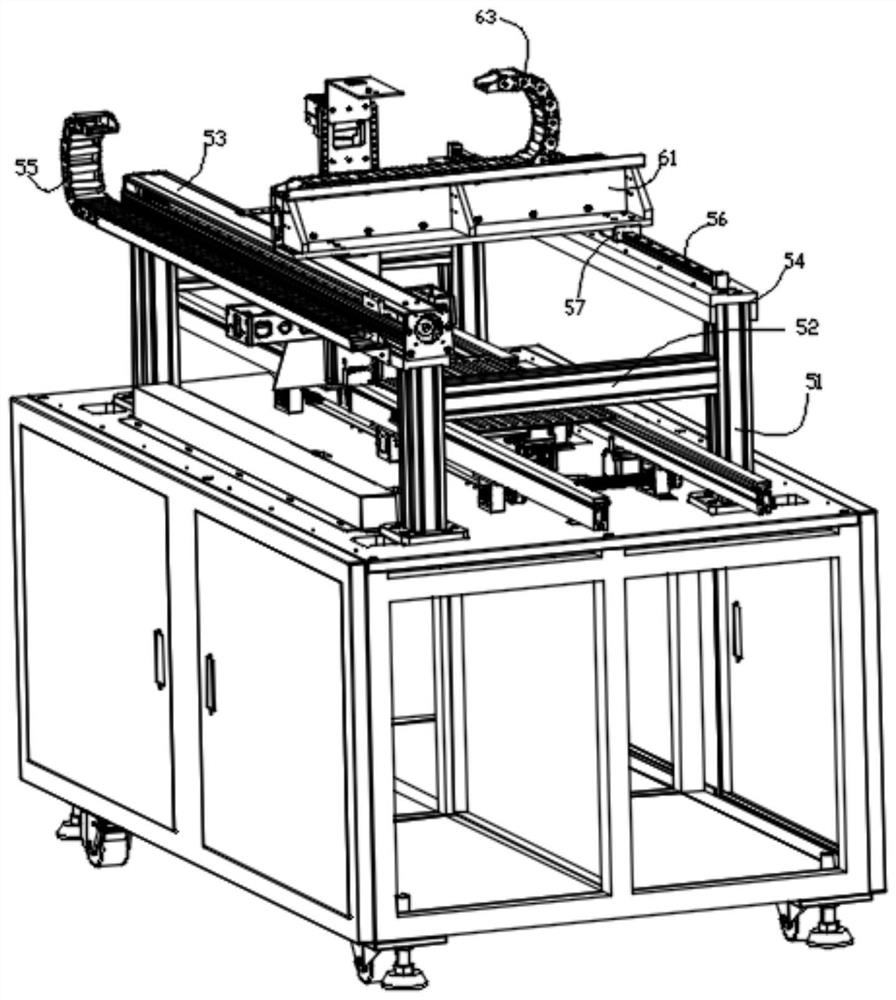

[0039] like Figure 1-6 As shown, the present invention provides a visual inspection system for SPI solder paste printing, including an induction system: sensing and detecting whether the input of the product to be detected is detected,

[0040] The feeding system transfers the product to be tested to the tested area;

[0041] The scanning system detects the products conveyed by the feeding system, and the inspection content includes the printing effect of each solder joint and the area and thickness of the solder paste.

[0042] Data storage system, which stores the detection data of the scanning system;

[0043] Data statistical analysis system, to carry out statistics and analysis on the data scanned by the sca...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap