System and method for on-site mixed loading of emulsion explosives in tunnel blasting peripheral holes

A technology of emulsified explosives and on-site mixing, which is applied in tunnels, blasting, earthwork drilling and mining, etc. It can solve the problems that cannot fully reflect the technical advantages of on-site mixed emulsified explosives, cannot achieve smooth blasting, and multi-charges.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

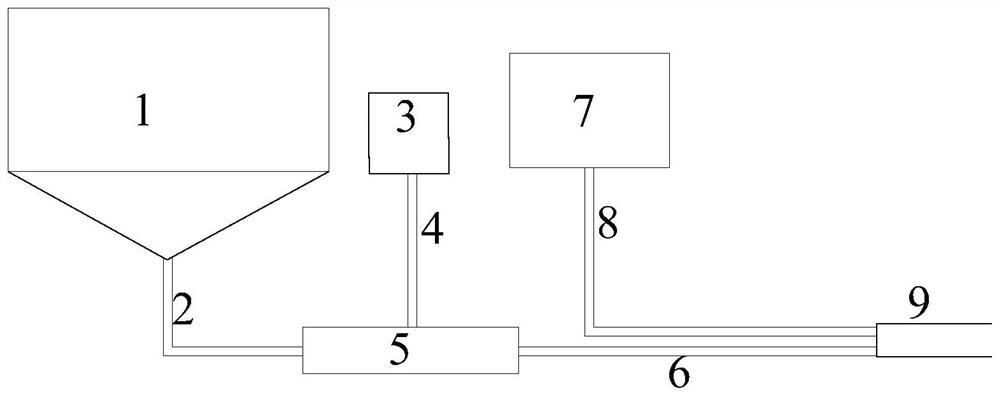

[0031] A system for on-site mixing of emulsion explosives in tunnel blasting peripheral holes, comprising a latex matrix storage tank 1, a latex matrix material delivery pipe 2, a sensitizer storage tank 3, a sensitizer material delivery pipe 4, and a mixed emulsion explosive pumping system 5. Drug delivery pipe 6, fast curing foam material storage tank 7, buffer foam material delivery pipe 8 and mixing generator 9;

[0032] The latex matrix storage tank 1 is respectively connected with the mixed emulsion explosive pumping system 5 through the latex matrix material delivery pipe 2 and the sensitizer storage tank 3 through the sensitizer material delivery pipe 4. The medicine pipe 6 communicates with the mixing generator 9 , and the fast curing foam material storage tank 7 is also communicated with the mixing generator 9 through the buffer foam material feeding pipe 8 .

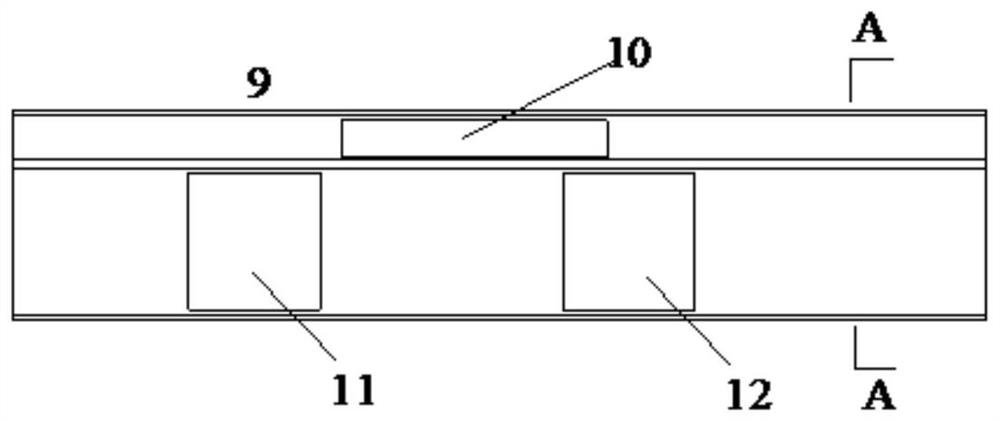

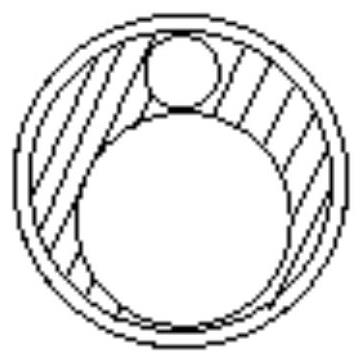

[0033] The mixing generator 9 includes a flow regulating device 10 , a first static mixing unit 11 and a se...

Embodiment 2

[0039] A method for using the above-mentioned system to realize the filling and mixing of emulsion explosives in peripheral holes of tunnel blasting, comprising the following steps:

[0040] (1) Add the latex matrix that meets the usage amount in the latex matrix storage tank 1, add the sensitizer that meets the usage amount in the sensitizer storage tank (3), and add the sensitizer that meets the usage amount in the fast-curing foam storage tank 7 foam cushioning material;

[0041] (II) The latex matrix and the sensitizer are respectively transported to the mixed emulsion explosive pumping system 5 through the latex matrix feed pipe 2 and the sensitizer feed pipe (4);

[0042] (III) The latex matrix and the sensitizer are pumped to the mixing generator 9 through the drug delivery pipe 6 by the mixed emulsion explosive pumping system 5 to be fully mixed to generate the emulsion explosive; Delivered to the mixing generator 9 through the buffer foam material feeding pipe 8;

[0...

Embodiment 3

[0050] A system for on-site mixing of emulsion explosives in tunnel blasting peripheral holes, comprising a latex matrix storage tank 1, a latex matrix material delivery pipe 2, a sensitizer storage tank 3, a sensitizer material delivery pipe 4, and a mixed emulsion explosive pumping system 5. Drug delivery pipe 6, fast curing foam material storage tank 7, buffer foam material delivery pipe 8 and mixing generator 9;

[0051] The latex matrix storage tank 1 is respectively connected with the mixed emulsion explosive pumping system 5 through the latex matrix material delivery pipe 2 and the sensitizer storage tank 3 through the sensitizer material delivery pipe 4. The medicine pipe 6 communicates with the mixing generator 9 , and the fast curing foam material storage tank 7 is also communicated with the mixing generator 9 through the buffer foam material feeding pipe 8 .

[0052] The mixing generator 9 includes a flow regulating device 10 , a first static mixing unit 11 and a se...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com