Five-step construction method for three steps of IV-stage surrounding rock ultra-large cross section

A technology of ultra-large section and construction method, which is applied in the construction of tunnel section and the field of three-step and five-step construction of super-large section of Class IV surrounding rock, which can solve the problems of difficult adjustment of construction method, difficulty of construction organization, and reduction of work efficiency in tunnels with soft and hard surrounding rocks , to achieve the effect of facilitating the rapid operation of large machinery and the conversion of construction methods, the arrangement of construction procedures is reasonable, and the effect of saving construction time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

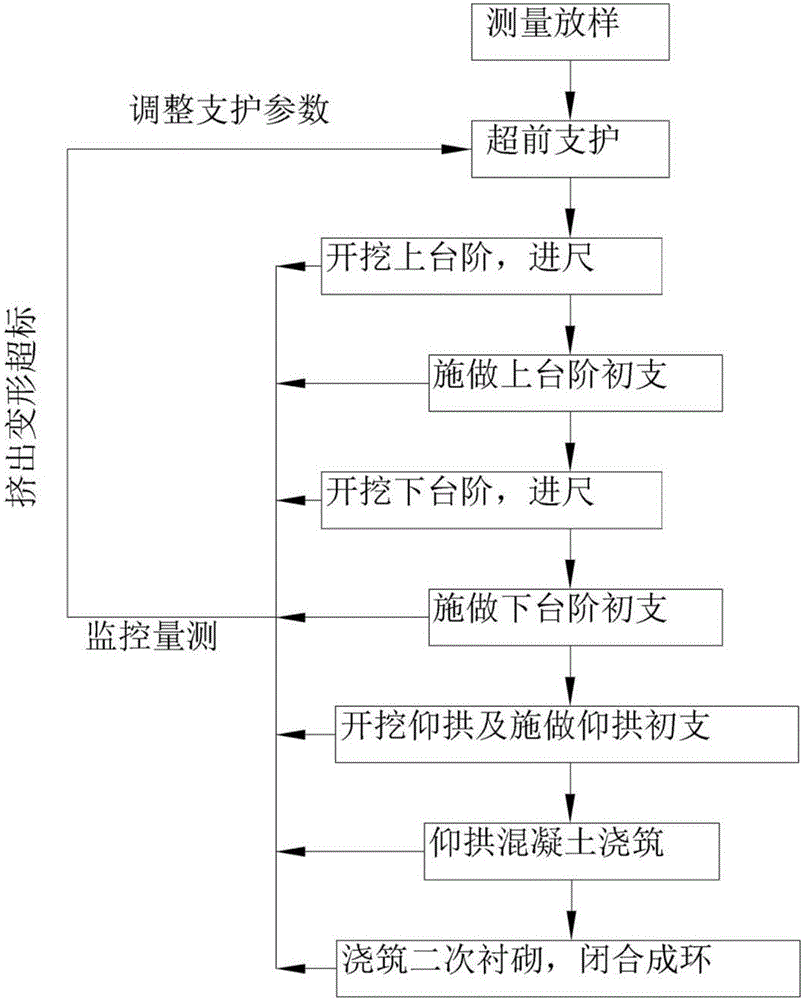

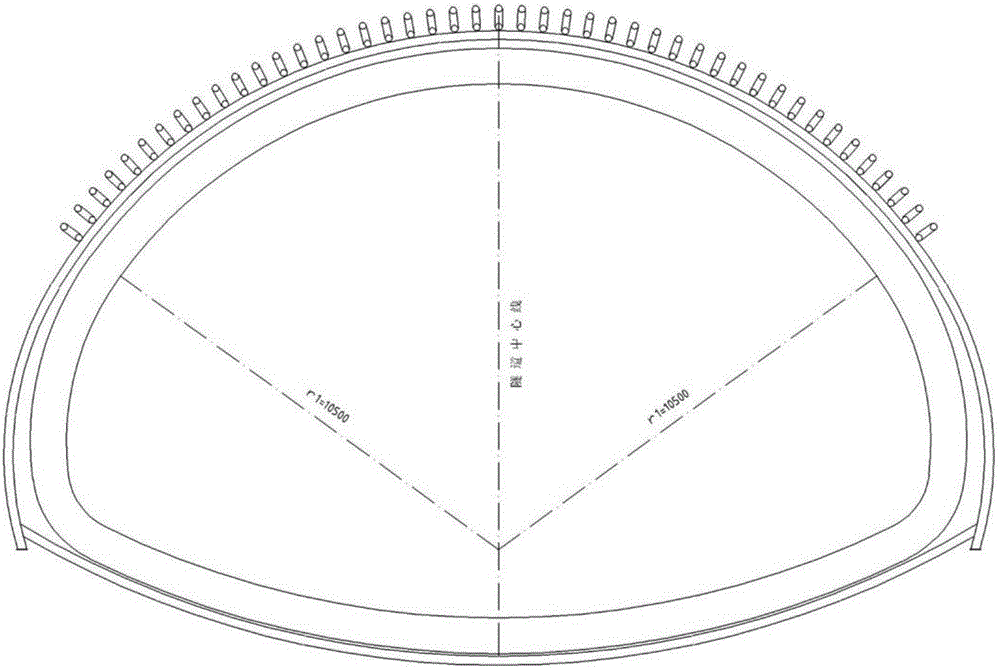

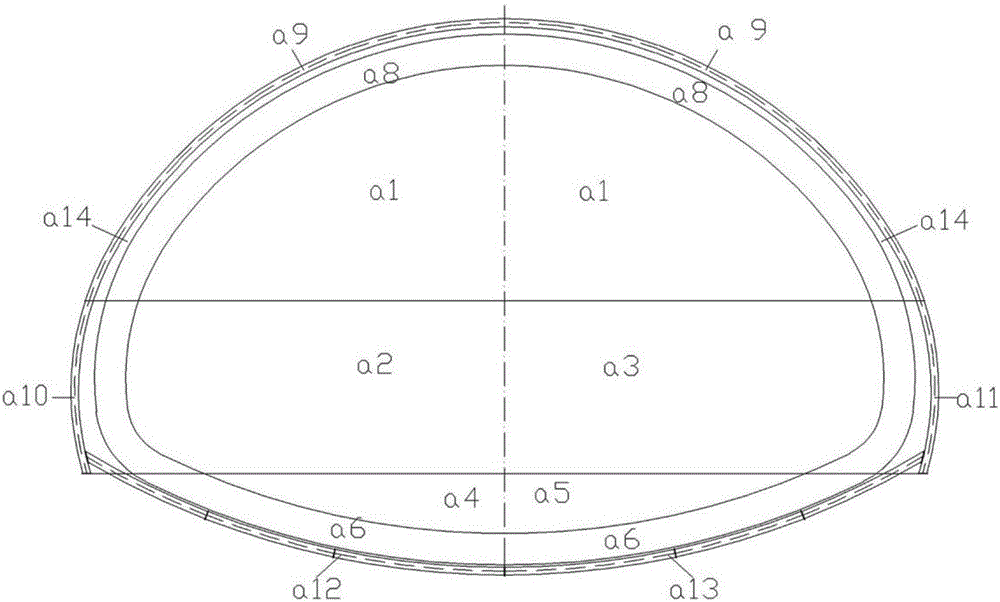

[0059] Such as Figure 1-Figure 5 As shown, a three-step five-step construction method for a super-large section of Class IV surrounding rock,

[0060] S1, advance support;

[0061]S11. Before circular excavation footage, clean up the tunnel face and mark the contour lines of excavation and blasting, and carry out advance support construction on the steel arch foundation of the previous cycle.

[0062] S2. Excavate the steps and carry out initial support. The excavated steps do not leave core soil. During the blasting and excavation process, the cutting is wedge-shaped cutting, and the blast hole adopts a small-diameter charge coil without coupling charge structure;

[0063] S21, excavation of the upper step a1, the height of the upper step is about 6m, after the blasting and excavation is completed, the initial support a9 of the upper step shall be implemented in time, and the deformation monitoring of the working face shall be carried out;

[0064] S22, Excavate the middle...

Embodiment 2

[0078] It differs from Embodiment 1 in that:

[0079] Such as Figure 5 , Figure 6 , Figure 7 , Figure 9 As shown, the tunnel surface is reinforced in advance by using the mobile support device 1 .

[0080] The mobile support device 1 includes a base 11 and a hydraulic output assembly 12, the hydraulic output assembly 12 is installed on the base 11; there are multiple hydraulic output assemblies 12; the output of each hydraulic output assembly 12 Each end is provided with a pressure bearing plate 121 , and the output end of the hydraulic output assembly 12 is perpendicular to the pressure bearing plate 121 .

[0081] Such as Figure 7 As shown, the hydraulic output assembly 12 includes a supporting hydraulic cylinder 122 and a steering hydraulic cylinder 123, and the steering hydraulic cylinder 123 controls the swinging of the supporting hydraulic cylinder 122; one end of the supporting hydraulic cylinder 122 is hinged to the base 11 , the other end of the supporting ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com