Method for automatically detecting leakage

An automatic detection and leakage technology, which is applied in the directions of measurement, earthwork drilling and production, wellbore/well components, etc., can solve the problems that the sealing fluid cannot be detected accurately, does not appear, and affects the efficiency of swabbing operation, etc., to ensure that The effect of safe operation, improvement of work efficiency and guarantee of safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

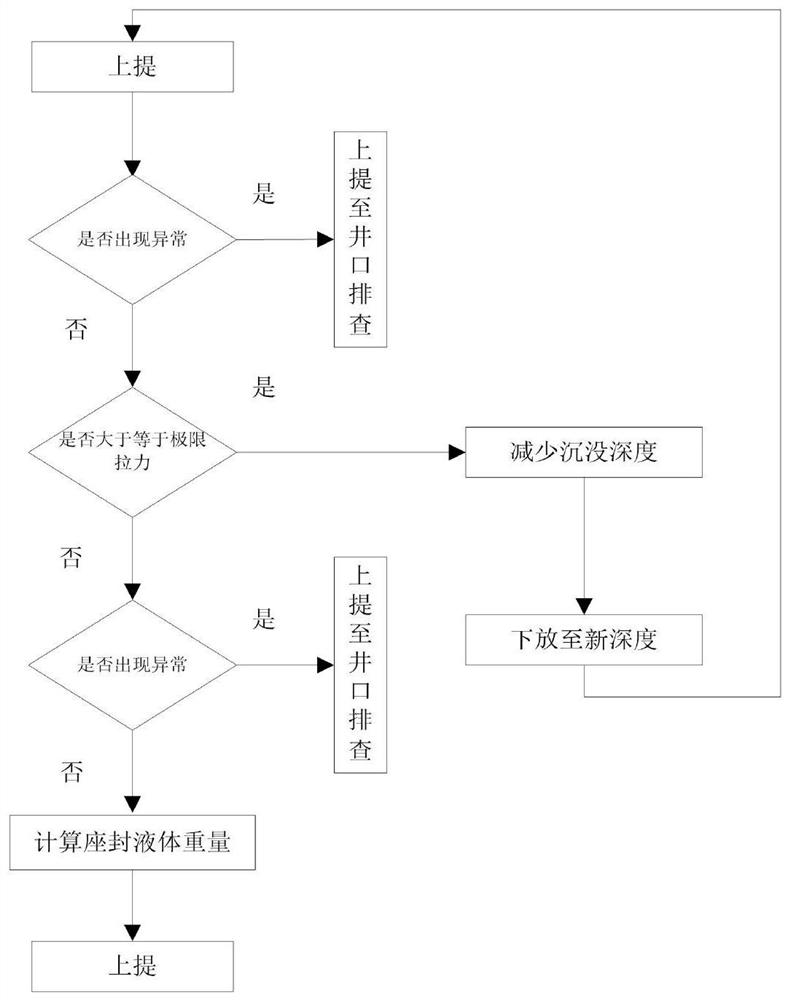

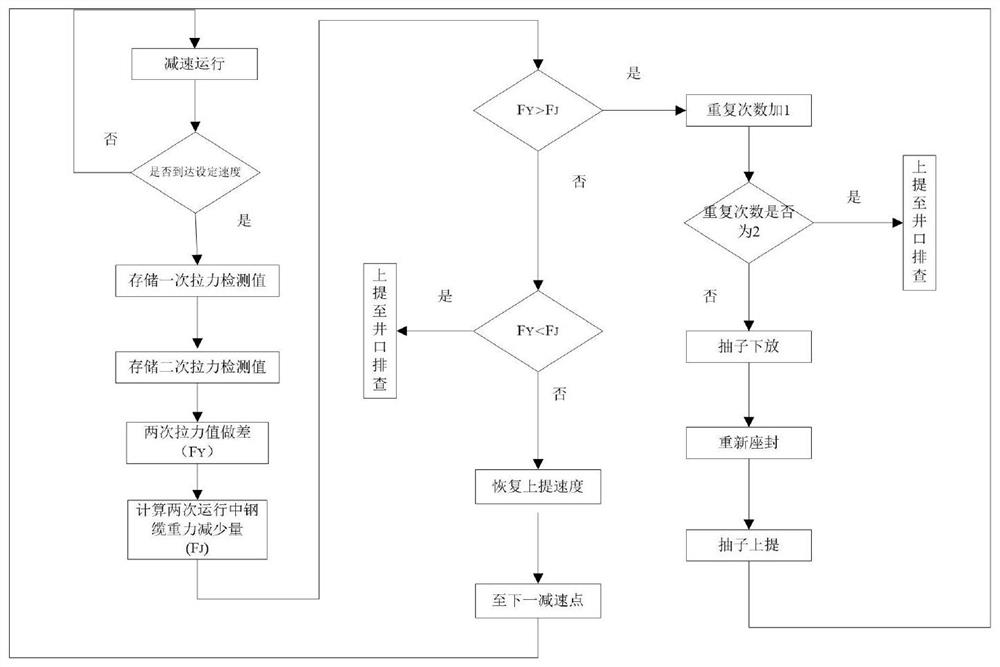

[0028] see Figure 1 to Figure 2 , an automated method for detecting leaks, comprising the following steps:

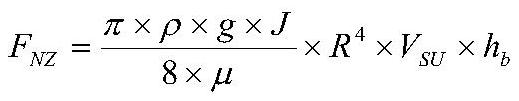

[0029] S1) During the sealing process, the tensiometer collects the lifting force of the steel cable in the process of swabbing and sealing in real time, and judges in real time whether the lifting force of the steel cable during the seat sealing is greater than the limit pulling force of the swabbing. If the lifting force of the wire rope is greater than the ultimate pulling force of the swabbing, it is judged that the calculated sunk depth is wrong, the sunk depth should be reduced, and the lifting force should be re-raised; again, judge the pulling-up pulling force and the swabbing limit of the steel wire rope detected by the tensiometer. The relationship between the pulling force, until the pull-up pulling force data of the pull-out steel cable detected by the tensiometer is less than the ultimate pulling force of the swabbing, find out the correct subsidence depth...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com