Wire inserting method of high-speed motor winding

A high-speed motor and winding technology, used in windings, electric components, manufacturing of motor generators, etc., can solve the problems of a large number of poles, the difficulty of inserting the stator coil, and the inability to complete the insertion, and achieve the effect of solving the large centrifugal force.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described below in conjunction with the accompanying drawings.

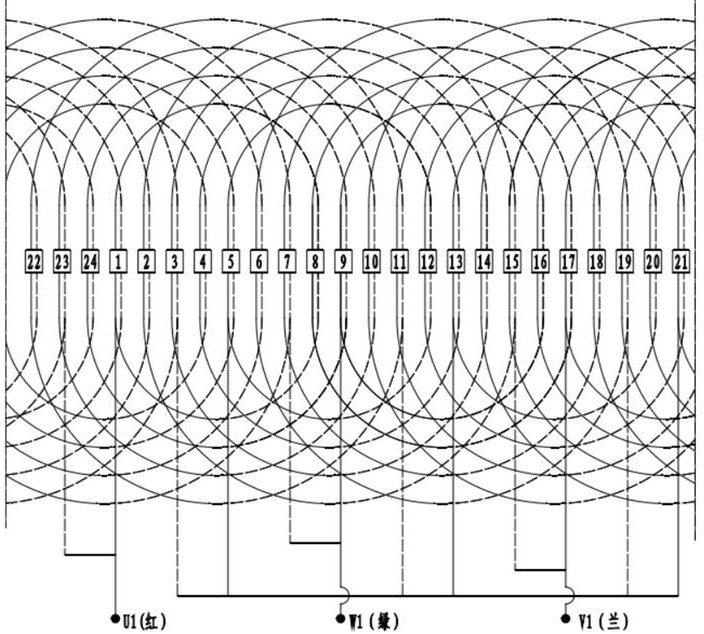

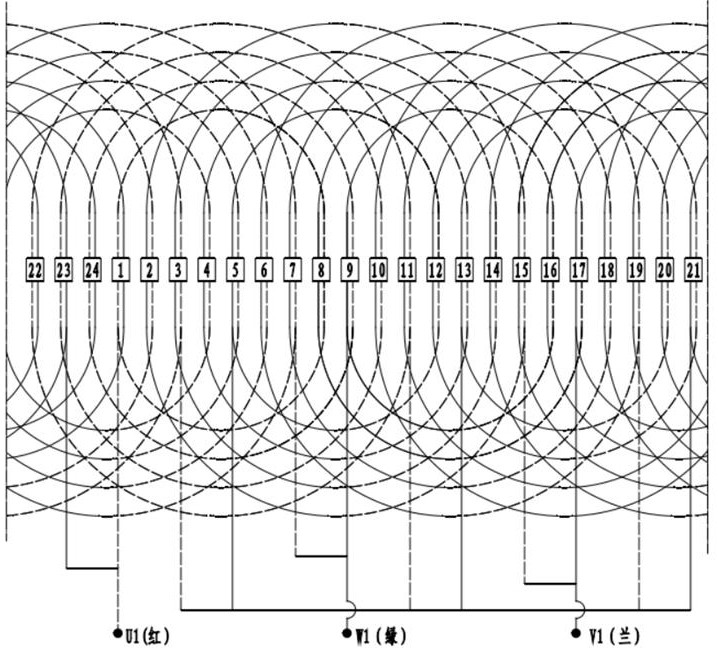

[0027] like figure 1 A method of embedding the windings of a high-speed motor as shown, the stator core has a total of 24 embedding slots, and all four connected coils of the first phase coil are embedded in the lower side, so that there are 10 unembedded coil sides in the stator core. The number is reduced to 6, which completely solves the problem of wire embedding of motors with small inner diameters.

[0028] The specific wire embedding process is as follows: firstly, the two coil sides of the smallest coil among the four connected coils of the first phase coil are embedded, and both are embedded in the lower layer, and then the two coil sides of the smaller coil among the four connected coils of the first phase coil are embedded. Each coil side is also embedded in the lower layer, and then the two coil sides of the larger coil among the four connected coils of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com