Double-turntable multi-station tool sharpener for high-end equipment manufacturing

A double-turntable, multi-station technology, which is applied to manufacturing tools, machine tools suitable for grinding workpiece planes, and parts of machine tools, can solve the problems of reducing the efficiency of grinding and increasing the complexity of the operation process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

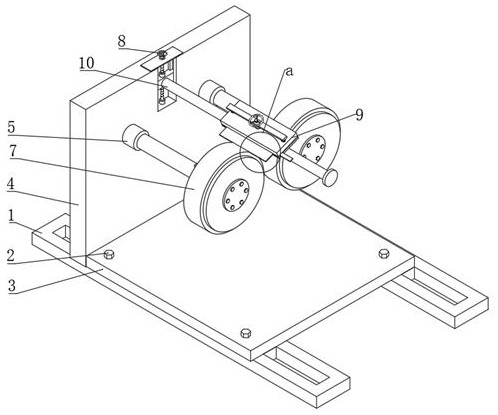

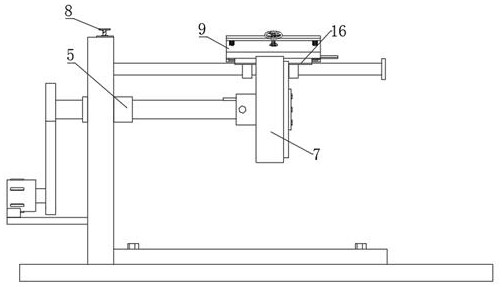

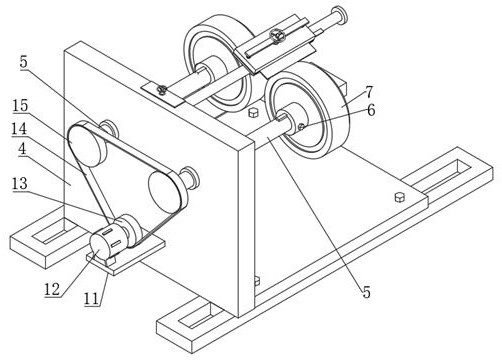

[0031] like Figure 1-8 As shown, a double-turntable multi-station sharpener for high-end equipment manufacturing includes a base 1, a base plate 3 is fixedly installed on the upper surface of the base 1 through a first bolt 2, and a vertical plate 4 is fixedly installed on the upper surface of the base plate 3, The interior of the vertical plate 4 is rotatably installed with a connecting shaft 5, the two connecting shafts 5 are arranged symmetrically, and the ends of the two connecting shafts 5 away from the vertical plate 4 are fixedly installed with a grinding roller 7 through the second bolt 6, one of which is a grinding roller. The periphery of the wheel 7 is in close contact with the cutter body 16, and an adjustment assembly 8 is arranged inside the vertical plate 4. The adjustment assembly 8 includes a micro screw rod 802 and a slider 804. The slider 804 is slidably installed inside the vertical plate 4. The micro screw rod 802 is installed inside the screw mounting pl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com