Non-woven fabric composite forming device

A composite molding, non-woven technology, which is applied to the device for coating liquid on the surface, lamination device, lamination auxiliary operation, etc. problems, to achieve the effect of easy precise adhesion, easy storage or spraying, and easy rapid prototyping

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

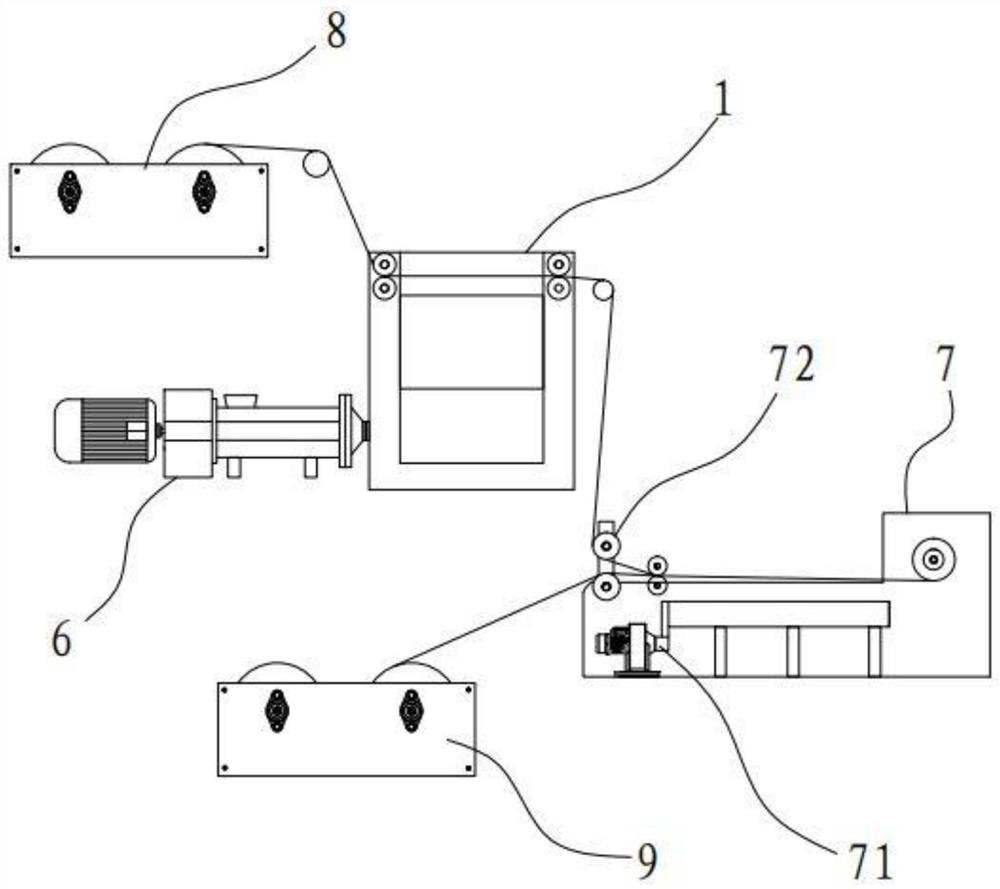

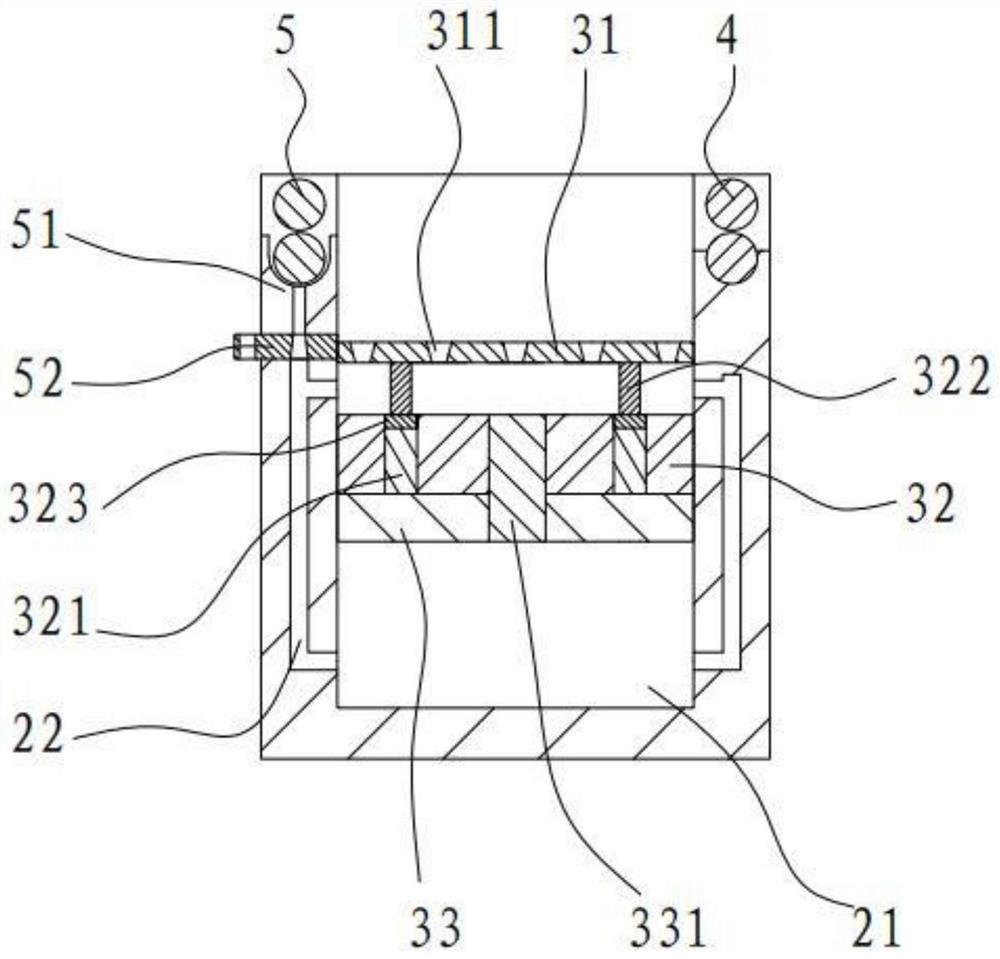

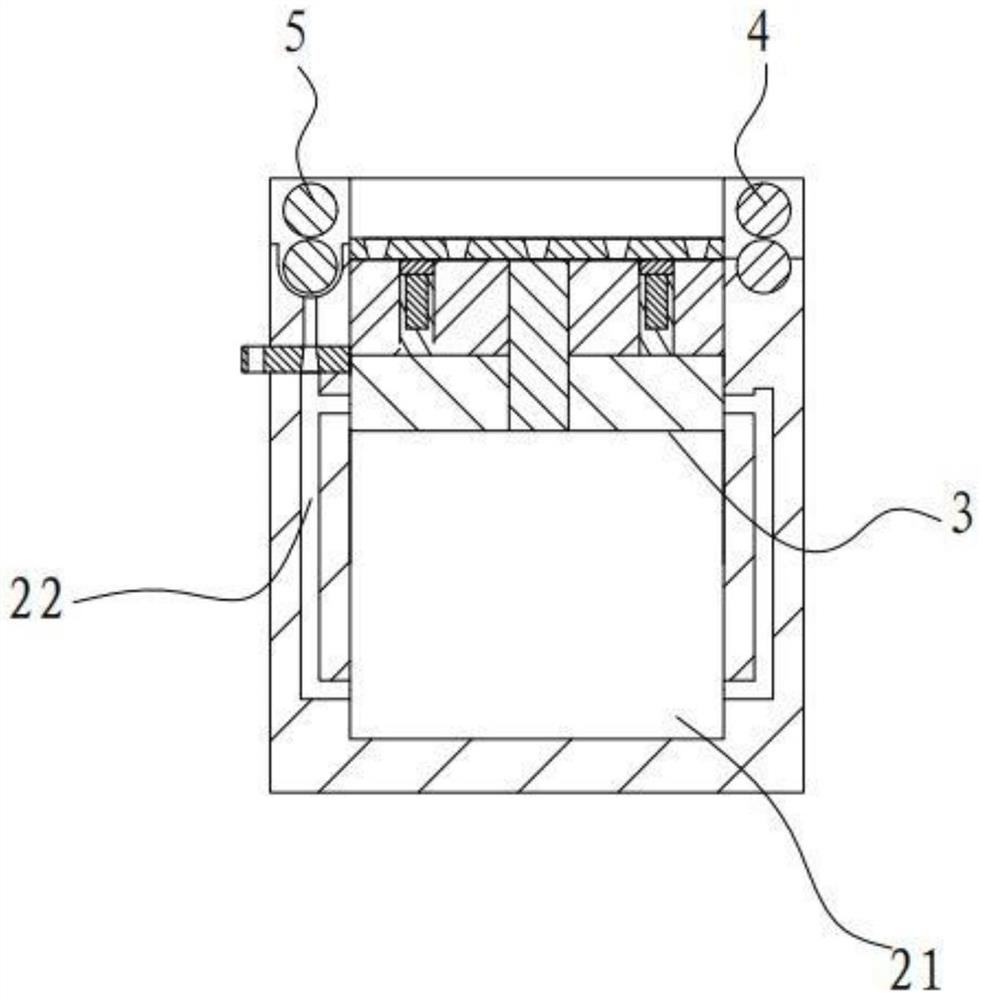

[0032] Attached to the following Figure 1-3 , the embodiments of the present invention will be described in further detail.

[0033] A non-woven fabric composite molding device, such as figure 1 As shown, it includes a non-woven material mechanism 8 , a functional cloth material mechanism 9 , a viscose mechanism 1 and a composite mechanism 7 .

[0034] The non-woven fabric material mechanism 8 and the functional fabric material mechanism 9 are respectively used to place the material roll made by winding the non-woven fabric and the functional fabric, and provide the storage space for the non-woven fabric and the functional fabric, which is convenient for the non-woven fabric to move to the viscose. Mechanism 1 outputs, so that the functional cloth is output to the composite mechanism 7; at least two material rolls can be placed in the non-woven material mechanism 8 and the functional cloth material mechanism 9, so that after one material roll is used, another material roll c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com