Full-automatic tiling and plastering machine

A plastering machine, fully automatic technology, applied in construction, building structure and other directions, can solve the problems of low efficiency, slow plastering construction speed, etc., to increase the hitting area, improve the tiling effect and improve the construction efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

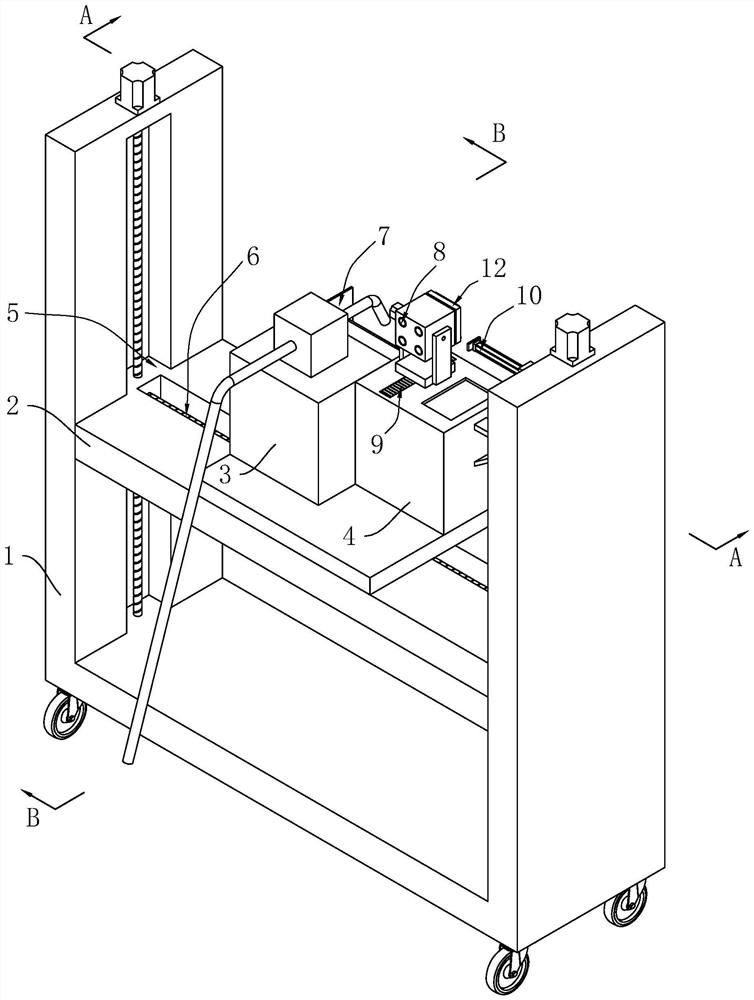

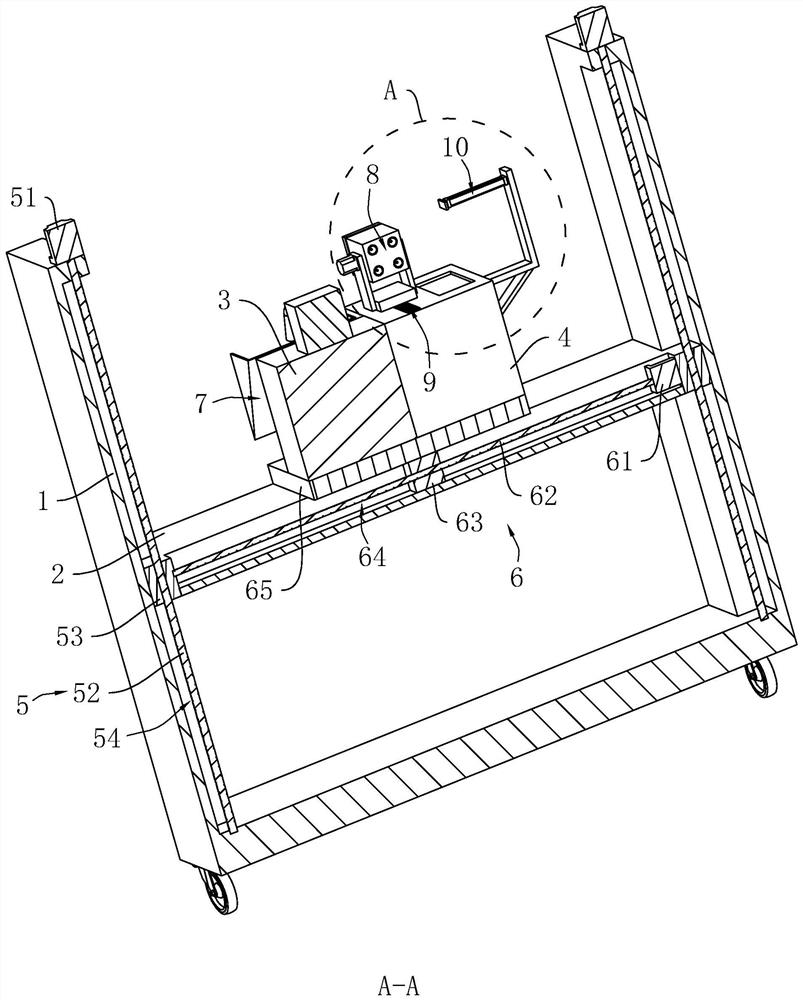

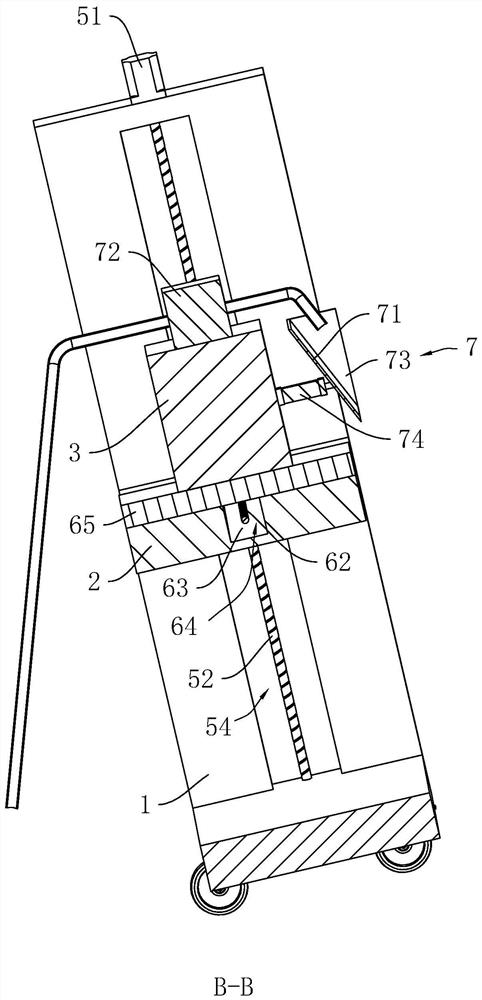

[0042] Attached to the following Figure 1-9 This application will be described in further detail.

[0043] The embodiment of the present application discloses a fully automatic tiling and plastering machine. refer to figure 1 and figure 2 , the fully automatic tiling and plastering machine includes a mobile frame 1, a lifting platform 2, a plastering platform 3 and a tiling platform 4. In this embodiment, the bottom of the mobile frame 1 is provided with several universal wheels, and through the universal wheels, It is convenient for the construction personnel to push the mobile frame 1 to move, and the lifting table 2 is slidingly connected to the mobile frame 1. The mobile frame 1 is provided with a longitudinal displacement mechanism 5 for driving the lifting table 2 to rise and fall, and the plastering table 3 and the tiling table 4 are arranged side by side. On the lifting table 2, and the plastering table 3 and the tiling table 4 are both slidingly connected to the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com