Die repairing method of stamping die

A technology for stamping dies and repairing dies, which is applied to instruments, measuring devices, mechanical devices, etc., can solve the problems of not taking into account the springback parameters of stamping workpieces, the waste of production materials and processing procedures, and the deviation of stamping workpieces, so as to reduce repairs. The number of molds, the improvement of mold repair accuracy, and the effect of improving the qualified rate of finished products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described below with reference to the embodiments and the accompanying drawings.

[0031] The invention provides a method for repairing a stamping die, wherein the technical points can be carried out according to the following steps:

[0032] S1. Perform stamping production on the initial die to obtain a stamped workpiece;

[0033] S2. Detect the obtained stamping workpiece on the inspection tool, and measure the core data of each part of the stamping workpiece;

[0034] S3. Trim the corresponding part of the stamping die by referring to the core data obtained;

[0035] S4. Repeat steps S1 to S3 until the size of the stamping die meets the tolerance requirements.

[0036] Wherein, the detection mentioned in the step S2 is carried out according to the following steps:

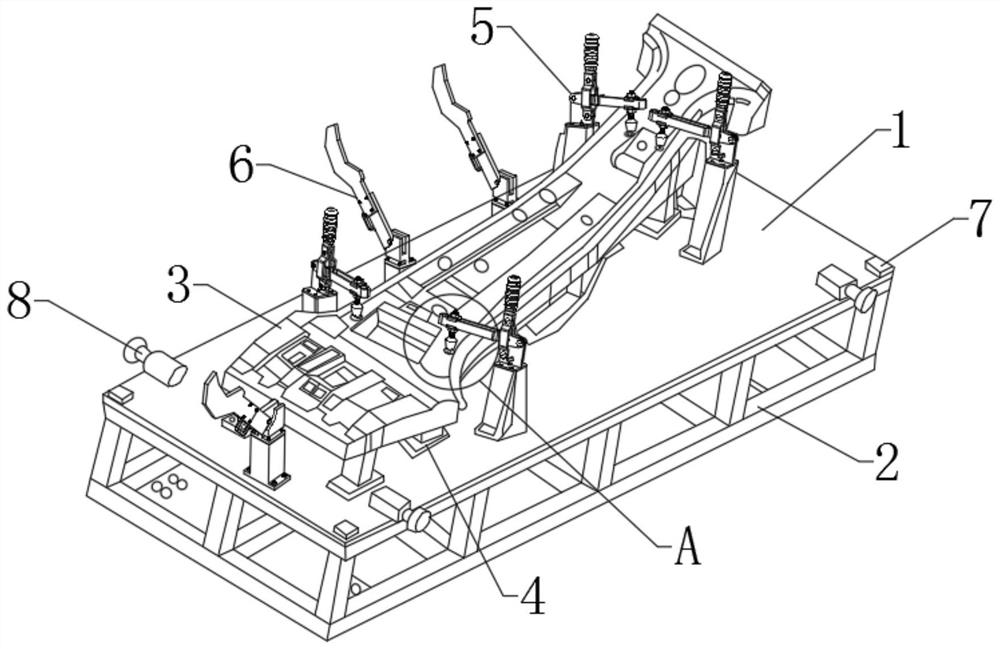

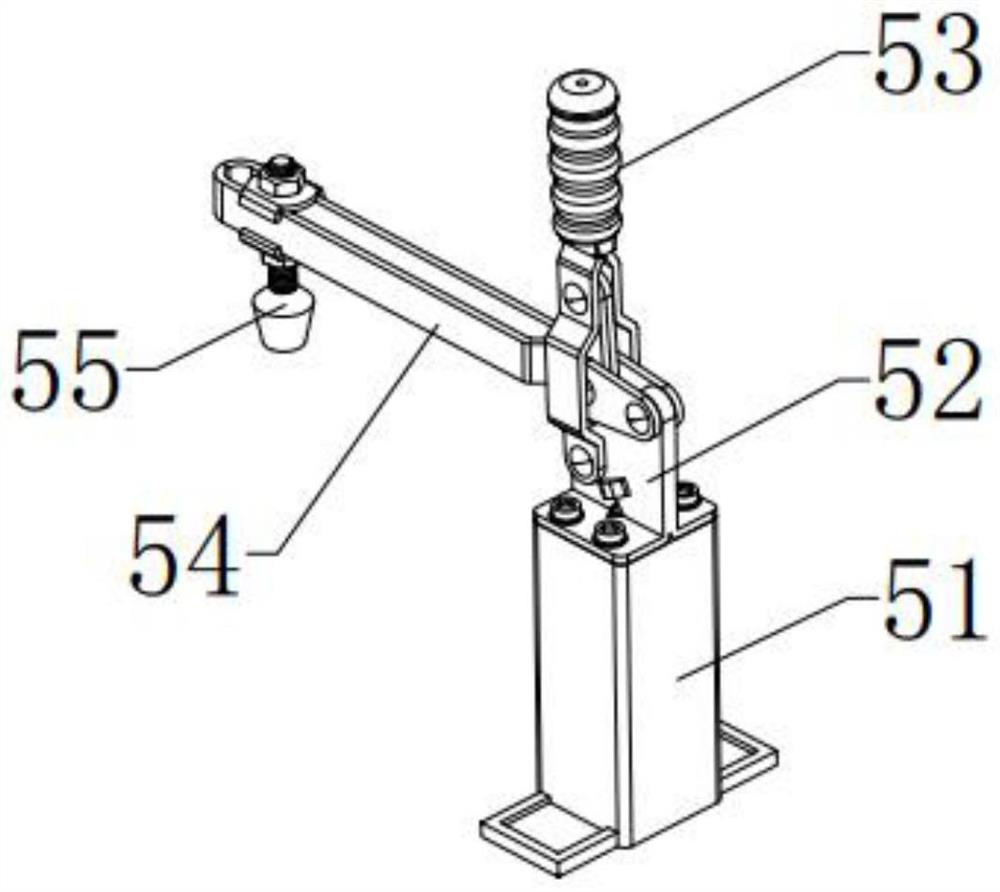

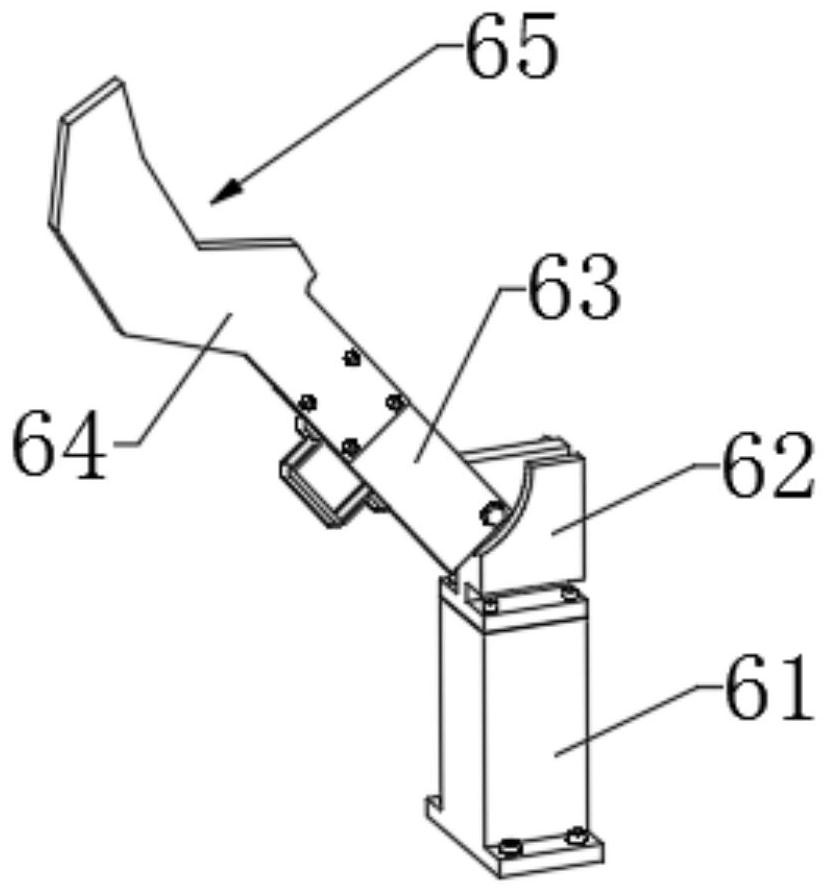

[0037] First, make sure that all the positioning pins 31 on the inspection tool are in a non-working state, and that each of the quick press clamps 5 and the inspe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com