Design method of quasi-zero stiffness vibration isolator

A quasi-zero stiffness and design method technology, applied in design optimization/simulation, instrumentation, geometric CAD, etc., can solve problems such as lack of design methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will now be further described with reference to the accompanying drawings and specific embodiments.

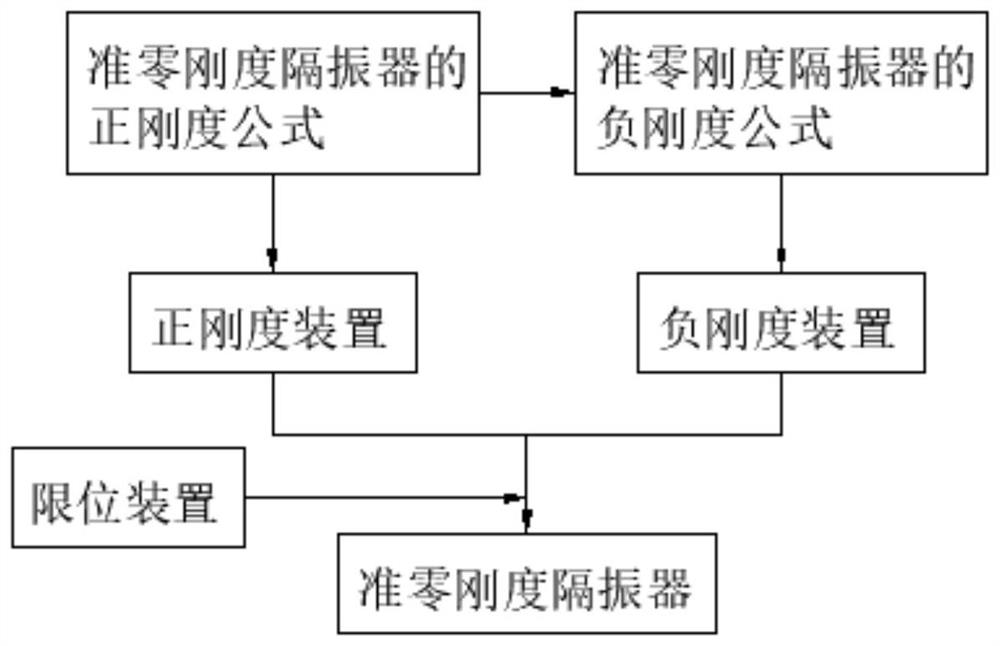

[0018] like figure 1 As shown, a method for designing a quasi-zero stiffness vibration isolator provided in this embodiment includes the following steps:

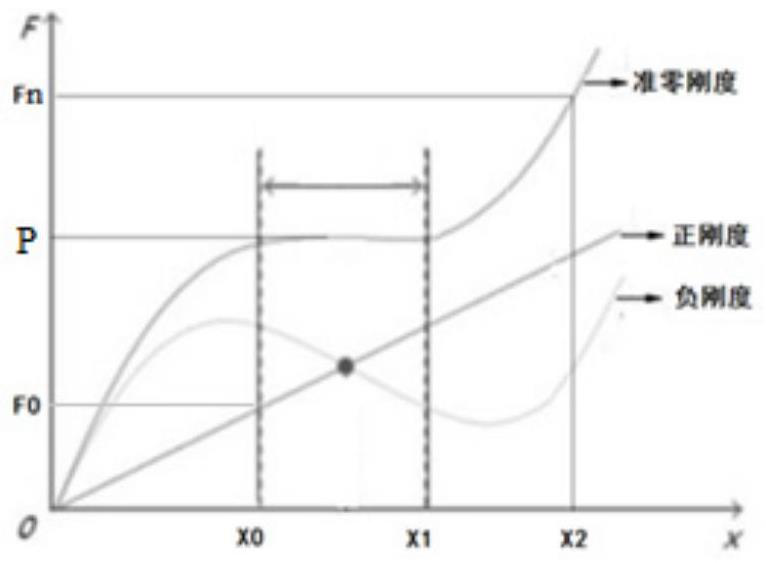

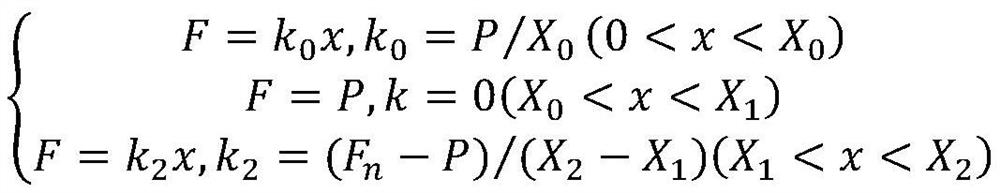

[0019] S1: Determine the bearing capacity requirement of the quasi-zero stiffness vibration isolator, and calculate the static load stiffness k of the quasi-zero stiffness vibration isolator through the bearing capacity and pre-compression of the quasi-zero stiffness vibration isolator 0 , k 0 =P / X 0 , and when 00 time, k 0 =k 1 +k 2 ; in the formula, P is the bearing capacity of the quasi-zero stiffness vibration isolator, x is the amount of compression of the quasi-zero stiffness vibration isolator relative to the original state, X 0 The pre-compression of the quasi-zero stiffness vibration isolator, that is, the lower limit of the working deformation of the quasi-zero stiffness vibratio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com