Test bench

A technology of test benches and test pieces, applied in the field of test benches, can solve problems such as single test methods, and achieve the effect of enriching test methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] In order to make the principles and technical solutions of the present application clearer, the embodiments of the present application will be further described in detail below with reference to the accompanying drawings.

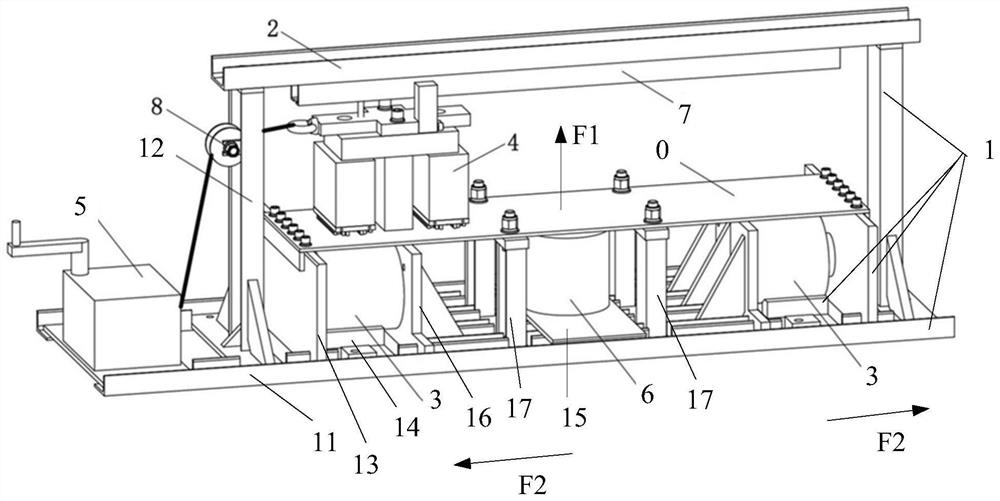

[0035] figure 1 It is a schematic structural diagram of a test bench provided by the embodiment of the present application. The test bench includes:

[0036] A test bed base 1 , a test bed beam 2 , a first pressure unit 3 , a stress signal acquisition unit 4 and a drive unit 5 .

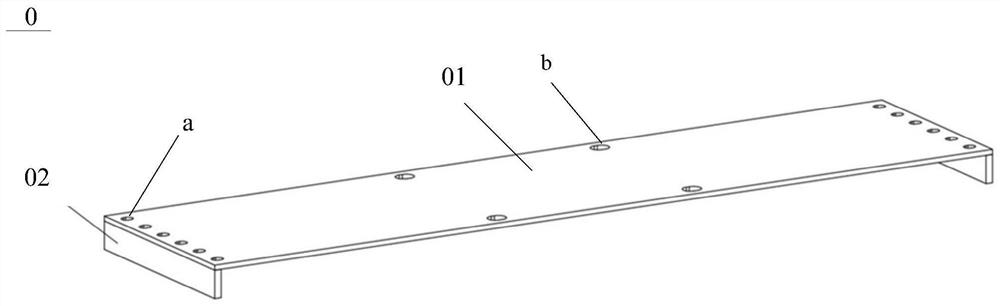

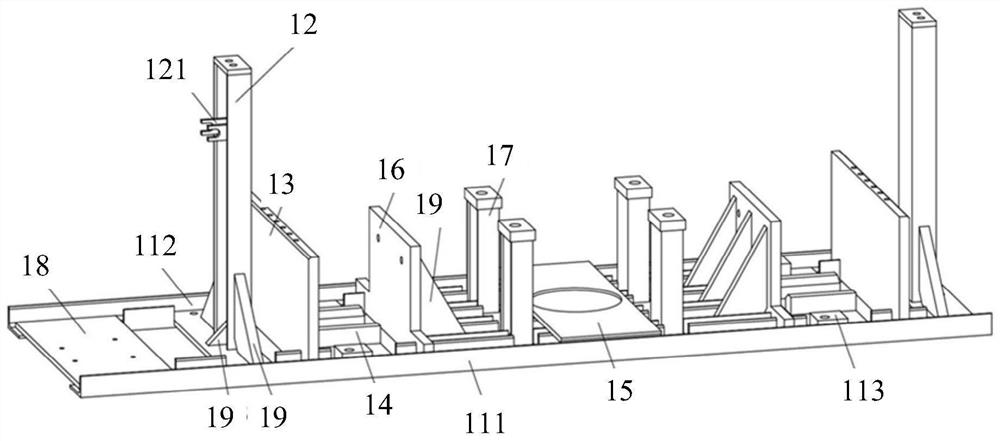

[0037] The test bed base 1 includes a bottom plate 11 , a beam fixing frame 12 and two test piece fixing frames 13 . One end of the beam fixing frame 12 is fixedly connected to the bottom plate 11 , and the other end is fixedly connected to the test bench beam 2 . Exemplarily, the test bed base 1 includes two beam fixing frames 12 , and the two beam fixing frames 12 are respectively fixed to both ends of the test bed beam 2 to stably support the test bed beam 2 . Exempl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com