Method for testing structural mechanical properties of polygonal building film

A thin-film structure and polygonal technology, which is applied in the field of testing the mechanical properties of polygonal building thin-film structures, can solve the problems of long test period, slow calculation and analysis of test data, and poor test results.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0077] In order to make the objectives, technical solutions and advantages of the present invention clearer, the present invention will be further described in detail below with reference to the embodiments. It should be understood that the specific embodiments described herein are only used to explain the present invention, but not to limit the present invention.

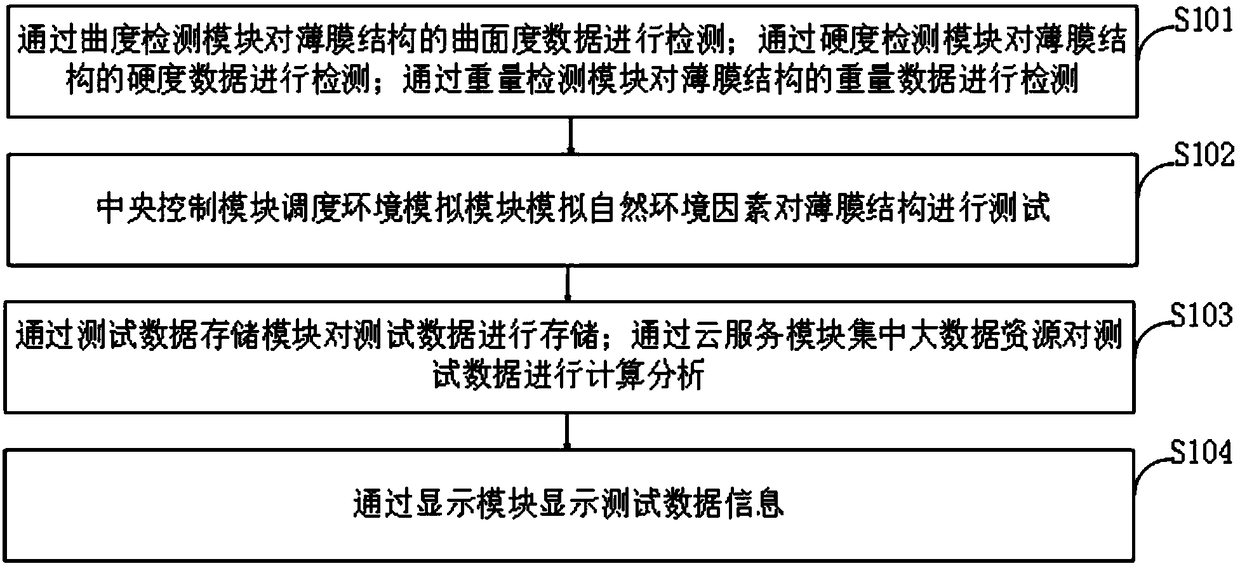

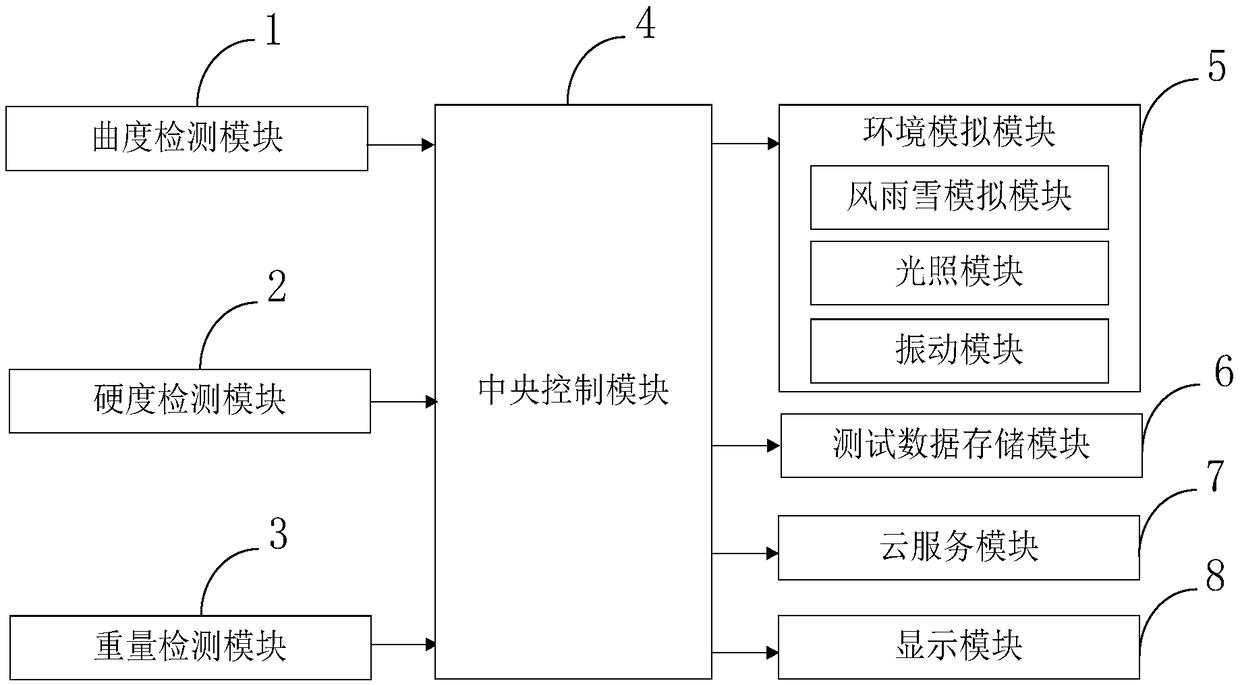

[0078] like figure 1 As shown, the method for testing the mechanical properties of a polygonal building membrane structure provided by the embodiment of the present invention includes the following steps:

[0079] S101, the curvature data of the thin film structure is detected by the curvature detection module; the hardness data of the thin film structure is detected by the hardness detection module; the weight data of the thin film structure is detected by the weight detection module;

[0080] S102, the central control module dispatches the environment simulation module to simulate natural environment factors to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com